IMVELISOINTSHAYELELO

Ibha yentsimbi ENGANDAYO

Cold drawn steel can be found in many consumer products that we use on a daily basis, as it has the physical and appealing characteristics that make it useful for many products. We’ve answered some common questions asked when it comes to cold drawn steel, also known as cold finished steel.

Yintoni iCold Drawn Steel?

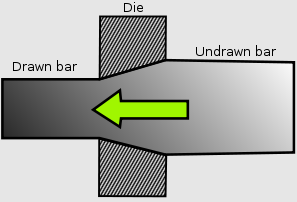

Intsimbi ezotyiweyo idlula kuthotho lweentsizi ukufikelela kwimilo efunekayo yaziwa ngokuba yintsimbi ezotyiweyo. Abafayo basebenzise inani elichaziweyo loxinzelelo ngoncedo lomatshini wokushicilela, kwaye isitokhwe sokuqala sentsimbi ngokuqhelekileyo kufuneka sidluliselwe kwi-die okanye uchungechunge lokufa ngaphezu kwexesha elilodwa. Ukubanda kubhekiselele kwintsimbi ezotyiweyo eyenziwa kubushushu begumbi, obufuna uxinzelelo olongezelelweyo lokubumba intsimbi, kodwa inika intsimbi iimpawu ezongezelelweyo kunye nenkangeleko yobuhle obubonakalayo.

What’s the Cold Drawn Steel Process?

Initially, a steel manufacturer starts with a starting stock of steel product – either hot rolled straight bars or hot rolled steel coils - that is brought down to room temperature. Regardless if the end product is bar, tube or wire, the undrawn steel product is drawn through a die, which stretches the starting stock into the desired shape and size. This is done with the help of a grip that attaches to the steel stock and pulls the steel through the die. To the naked eye, the steel does not change much in shape through a single pass through the die, and usually takes multiple passes before it takes on the desired end shape.

Ezi ziinzuzo zeCold Drawn Steel Wire

· More accurate dimensional size tolerances.

· Increased Mechanical Properties, higher yield strengths, tensile strength and hardness.

· Improved Surface Finish, reduces surface machining and improves quality.

· Allows for higher machining feed rates.

· Superior Formability, responds better to spheroidization

· Maximizes machinability, thereby reducing yield loss.