PRODUCTEINTRODUCCIÓ

Barra d'acer embotit en fred

Cold drawn steel can be found in many consumer products that we use on a daily basis, as it has the physical and appealing characteristics that make it useful for many products. We’ve answered some common questions asked when it comes to cold drawn steel, also known as cold finished steel.

Què és l'acer estirat en fred?

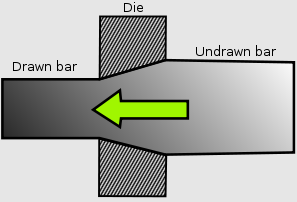

L'acer que s'estira passa per una sèrie de matrius per aconseguir la forma desitjada es coneix com a acer estirat. Les matrius apliquen una quantitat especificada de pressions amb l'ajuda d'una premsa de màquina, i el material inicial d'acer normalment s'ha de passar per la matriu o una sèrie de matrius més d'una vegada. El fred fa referència al fet que l'acer estirat es fabriquen a temperatura ambient, la qual cosa requereix una pressió addicional per donar forma a l'acer, però li dóna qualitats addicionals i un aspecte visualment estètic.

What’s the Cold Drawn Steel Process?

Initially, a steel manufacturer starts with a starting stock of steel product – either hot rolled straight bars or hot rolled steel coils - that is brought down to room temperature. Regardless if the end product is bar, tube or wire, the undrawn steel product is drawn through a die, which stretches the starting stock into the desired shape and size. This is done with the help of a grip that attaches to the steel stock and pulls the steel through the die. To the naked eye, the steel does not change much in shape through a single pass through the die, and usually takes multiple passes before it takes on the desired end shape.

Aquests són els avantatges del filferro d'acer estirat en fred

· More accurate dimensional size tolerances.

· Increased Mechanical Properties, higher yield strengths, tensile strength and hardness.

· Improved Surface Finish, reduces surface machining and improves quality.

· Allows for higher machining feed rates.

· Superior Formability, responds better to spheroidization

· Maximizes machinability, thereby reducing yield loss.