製品導入

冷間引抜鋼棒

Cold drawn steel can be found in many consumer products that we use on a daily basis, as it has the physical and appealing characteristics that make it useful for many products. We’ve answered some common questions asked when it comes to cold drawn steel, also known as cold finished steel.

冷間引抜鋼とは何ですか?

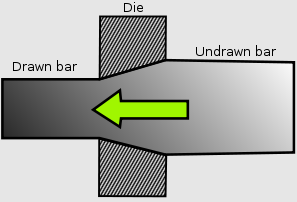

引き抜かれた鋼は、一連の金型を通過して所望の形状を達成し、引き抜き鋼として知られています。金型は機械プレスの助けを借りて指定された量の圧力を加えます。通常、鋼の出発素材はその金型または一連の金型を複数回通過する必要があります。冷間とは、引き抜き鋼が室温で製造されることを指します。これにより、鋼を成形するために追加の圧力が必要になりますが、鋼に特別な品質と視覚的な美的外観が与えられます。

What’s the Cold Drawn Steel Process?

Initially, a steel manufacturer starts with a starting stock of steel product – either hot rolled straight bars or hot rolled steel coils - that is brought down to room temperature. Regardless if the end product is bar, tube or wire, the undrawn steel product is drawn through a die, which stretches the starting stock into the desired shape and size. This is done with the help of a grip that attaches to the steel stock and pulls the steel through the die. To the naked eye, the steel does not change much in shape through a single pass through the die, and usually takes multiple passes before it takes on the desired end shape.

これが冷間引抜鋼線の利点です

· More accurate dimensional size tolerances.

· Increased Mechanical Properties, higher yield strengths, tensile strength and hardness.

· Improved Surface Finish, reduces surface machining and improves quality.

· Allows for higher machining feed rates.

· Superior Formability, responds better to spheroidization

· Maximizes machinability, thereby reducing yield loss.