PRODUITAféierung

KALT gezunn Stol Bar

Cold drawn steel can be found in many consumer products that we use on a daily basis, as it has the physical and appealing characteristics that make it useful for many products. We’ve answered some common questions asked when it comes to cold drawn steel, also known as cold finished steel.

Wat ass Kalt Drawn Steel?

Stol dat gezeechent gëtt passéiert duerch eng Serie vu Stierwen fir eng gewënscht Form z'erreechen ass bekannt als gezeechent Stol. Stierwen applizéiert spezifizéierter Quantitéit vun Drock mat der Hëllef vun enger Maschinn Press, an de Stol ugefaangen Stock typesch muss duerch d'Stuerwe oder eng Serie vun stierwen méi wéi eemol. Kale bezitt sech op dat gezeechent Stahl, dee bei Raumtemperatur hiergestallt gëtt, wat zousätzlech Drock erfuerdert fir de Stol ze formen, awer dem Stol extra Qualitéiten a visuell ästhetesch Erscheinung gëtt.

What’s the Cold Drawn Steel Process?

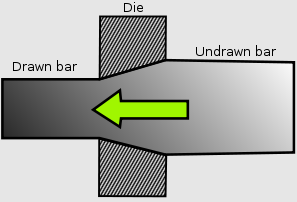

Initially, a steel manufacturer starts with a starting stock of steel product – either hot rolled straight bars or hot rolled steel coils - that is brought down to room temperature. Regardless if the end product is bar, tube or wire, the undrawn steel product is drawn through a die, which stretches the starting stock into the desired shape and size. This is done with the help of a grip that attaches to the steel stock and pulls the steel through the die. To the naked eye, the steel does not change much in shape through a single pass through the die, and usually takes multiple passes before it takes on the desired end shape.

Dëst sinn d'Virdeeler vum Cold Drawn Steel Wire

· More accurate dimensional size tolerances.

· Increased Mechanical Properties, higher yield strengths, tensile strength and hardness.

· Improved Surface Finish, reduces surface machining and improves quality.

· Allows for higher machining feed rates.

· Superior Formability, responds better to spheroidization

· Maximizes machinability, thereby reducing yield loss.