제품소개

냉간 인발 강철 바

Cold drawn steel can be found in many consumer products that we use on a daily basis, as it has the physical and appealing characteristics that make it useful for many products. We’ve answered some common questions asked when it comes to cold drawn steel, also known as cold finished steel.

냉간압연강판이란 무엇입니까?

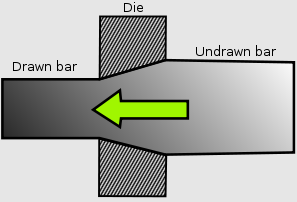

인발된 강철은 일련의 다이를 통과하여 원하는 모양을 얻기 위해 인발된 강철로 알려져 있습니다. 다이는 기계 프레스의 도움으로 지정된 양의 압력을 가하며 강철 시작 스톡은 일반적으로 다이 또는 일련의 다이를 두 번 이상 통과해야 합니다. 콜드(Cold)는 실온에서 제조되는 인발강을 말하며, 이는 강을 성형하기 위해 추가 압력이 필요하지만 강에 추가 품질과 시각적으로 미적인 외관을 제공합니다.

What’s the Cold Drawn Steel Process?

Initially, a steel manufacturer starts with a starting stock of steel product – either hot rolled straight bars or hot rolled steel coils - that is brought down to room temperature. Regardless if the end product is bar, tube or wire, the undrawn steel product is drawn through a die, which stretches the starting stock into the desired shape and size. This is done with the help of a grip that attaches to the steel stock and pulls the steel through the die. To the naked eye, the steel does not change much in shape through a single pass through the die, and usually takes multiple passes before it takes on the desired end shape.

냉간인발강선의 장점은 다음과 같습니다.

· More accurate dimensional size tolerances.

· Increased Mechanical Properties, higher yield strengths, tensile strength and hardness.

· Improved Surface Finish, reduces surface machining and improves quality.

· Allows for higher machining feed rates.

· Superior Formability, responds better to spheroidization

· Maximizes machinability, thereby reducing yield loss.