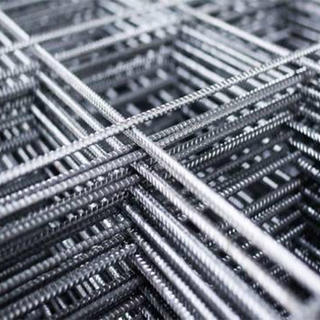

Reinforcing mesh, also known as welded wire mesh or rebar mesh, is a grid-like structure made from steel wires or bars welded together at intersections. It is widely used in construction to reinforce concrete structures, providing tensile strength and preventing cracks caused by shrinkage or external loads. The mesh is available in various sizes, wire diameters, and spacing configurations to suit different engineering requirements.

Commonly used in slabs, walls, pavements, and precast concrete elements, reinforcing mesh enhances structural integrity and distributes loads evenly. It offers advantages such as faster installation compared to traditional rebar, consistent spacing, and reduced labor costs. The material is typically made from carbon steel, stainless steel, or epoxy-coated steel to resist corrosion.

Reinforcing mesh improves durability and reduces the risk of structural failure, making it essential in modern construction. Its applications extend to industrial flooring, tunnel linings, and seismic-resistant structures. By integrating reinforcing mesh, builders ensure long-lasting, high-performance concrete projects with minimized maintenance needs.

What is reinforcing mesh used for?

Reinforcing mesh, also known as rebar mesh, is a grid-like structure made from steel wires or bars welded together at intersections. It is primarily used to strengthen concrete structures by providing tensile support, preventing cracks, and enhancing durability. Common applications include slabs, driveways, footings, and walls where concrete alone would be prone to cracking under stress. The mesh distributes loads evenly, reducing the risk of structural failure over time. It is widely used in residential, commercial, and industrial construction, as well as in infrastructure projects like bridges and roads. Reinforcing mesh is favored for its ease of installation, cost-effectiveness, and ability to improve the longevity of concrete elements. Additionally, it helps control shrinkage cracks that occur during the curing process. Whether for small DIY projects or large-scale engineering works, reinforcing mesh ensures that concrete maintains its integrity under pressure, weathering, and heavy use.

Galvanized vs Black Steel Reinforcing Mesh – Which One to Choose?

The choice between galvanized and black steel reinforcing mesh depends on the project's environmental conditions and corrosion resistance requirements. Galvanized mesh is coated with a protective zinc layer, making it highly resistant to rust and ideal for outdoor or high-moisture applications like coastal areas, swimming pools, and water treatment facilities. Black steel mesh, while more affordable, lacks corrosion protection and is best suited for indoor or dry environments where moisture exposure is minimal. Over time, unprotected black steel may rust, compromising structural integrity. For long-term durability in harsh conditions, galvanized mesh is the superior choice despite its higher upfront cost. However, if budget constraints are a priority and the structure is shielded from moisture, black steel can be a practical alternative. Engineers and contractors must evaluate exposure risks and project lifespan when selecting the appropriate type of reinforcing mesh.

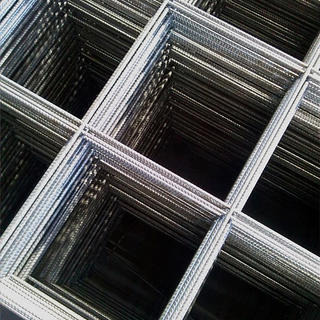

Custom Reinforcing Mesh Panels for Precast Concrete Applications

Custom reinforcing mesh panels are tailored to meet the specific dimensions and load-bearing requirements of precast concrete elements such as walls, beams, and columns. These panels are precision-engineered to fit exact design specifications, ensuring optimal reinforcement and reducing on-site labor. Precast concrete manufacturers benefit from custom mesh as it enhances production efficiency, minimizes material waste, and ensures consistent quality. The panels can be designed with varying wire thicknesses, spacing, and shapes to accommodate unique structural demands. Additionally, custom mesh improves the speed of assembly in precast plants, allowing for faster project completion. Whether for modular construction, tilt-up panels, or architectural precast elements, custom reinforcing mesh provides a reliable solution for reinforcing complex geometries. Its use contributes to the durability and performance of precast concrete, making it a preferred choice for modern construction projects that demand precision and scalability.