PRODUCTINTRODUCTION

Barbed wire introduction

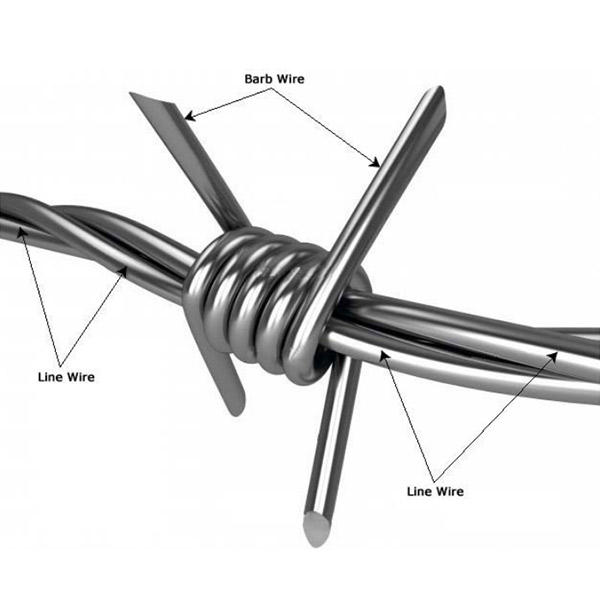

Barbed wire, a crucial element in the realm of fencing and security systems, is primarily crafted from high-quality low carbon steel wire or PVC wire. Offering a spectrum of colors like blue, green, yellow, and more, its versatility extends beyond mere functionality into the realm of aesthetics. The weaving process involves a specialized technique of twisting and weaving, lending barbed wire its unique, formidable characteristics.

This form of fencing material finds extensive utility across various landscapes and purposes. It is widely employed in farms, grasslands, boundary demarcations, railways, highways, prisons, and private venues. The multifaceted application of barbed wire spans from boundary demarcations to providing separation and protection in diverse settings.

Barbed wire emerges as an indispensable accessory in constructing woven wire fences, crucial in forming robust fencing and security systems. When used independently, it serves as a reliable means of protection along walls or buildings, where it is referred to as barbed wire fences or barbed obstacles. Its application extends beyond mere fencing; barbed wire is often referred to as barbed tape when employed in linear formations to create a type of tape configuration, emphasizing its adaptability in various security arrangements.

The properties of barbed wire make it an essential part of security infrastructure, ensuring both functional and visual significance. Its installation alongside fencing systems significantly enhances security measures, providing a formidable deterrent against unauthorized access and offering a sense of protection in diverse environments.

The choice of materials and colors not only ensures robustness but also allows for customization to match specific requirements. The range of colors provides an added layer of versatility, allowing barbed wire to integrate seamlessly into its surroundings, whether rural or urban, emphasizing both functionality and visual harmony. This adaptability extends its application further into varied domains, underscoring its significance in securing and demarcating spaces effectively and efficiently.

|

Barbed Wire Specification |

|||

|

Type |

Wire Gauge(SWG) |

Barbed Space(cm) |

Barbed Length(cm) |

|

Electric Galvanized Barbed wire; Hot dip zinc plating barbed wire |

10#×12# |

7.5-15 |

1.5-3 |

|

12#×12# |

|||

|

12#×14# |

|||

|

14#×14# |

|||

|

14#×16# |

|||

|

16#×16# |

|||

|

16#×18# |

|||

|

PVC coated barbed wire; PE barbed wire |

before coating after coating |

7.5-15 |

1.5-3 |

|

1.0-3.5mm 1.4-4.0mm |

|||

|

BWG11#-20# BWG8#-17# |

|||

|

BWG11#-20# BWG8#-17# |

|||

|

PVC/PE coating thickness: 0.4-0.6mm; Customization is available |

|||

Application: Barbed wire can be widely used as accessories for woven wires fences to form a fencing system or security system. It is called barbed wire fences or barbed obstacles when it is used simply by itself along the wall or the building to give a kind of protection. Barbed wire is also written as barbed tape as it is always used in a line to form a kind of tape