PRODUCTINTRODUCTION

|

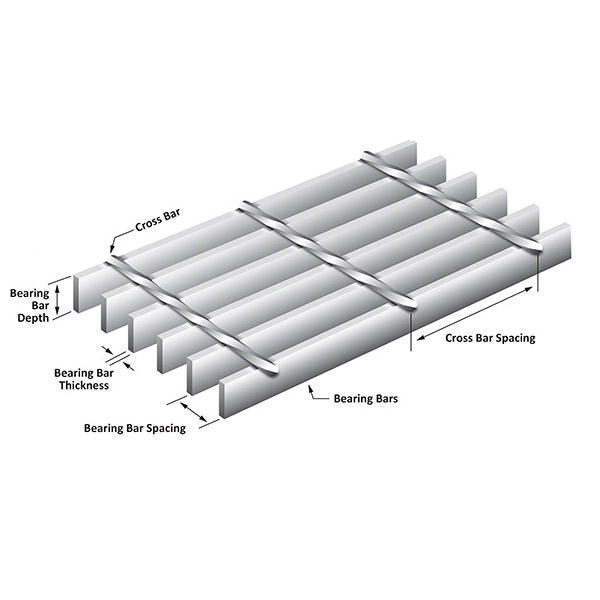

Item |

Description |

|

Bearing bar |

20x5, 25x3, 25x4, 25x5, 30x3, 30x4, 30x5, 32x3, 32x5, 40x5, 50…75x8mm, etc. |

|

Bearing bar pitch |

25, 30, 30.16, 32.5, 34.3, 40, 50, 60, 62, 65mm, etc. |

|

Cross bar |

5x5, 6x6, 8x8mm (twisted bar or round bar) |

|

Cross bar pitch |

40, 50, 60, 65, 76, 100, 101.6, 120, 130mm or as customers’ requirement. |

|

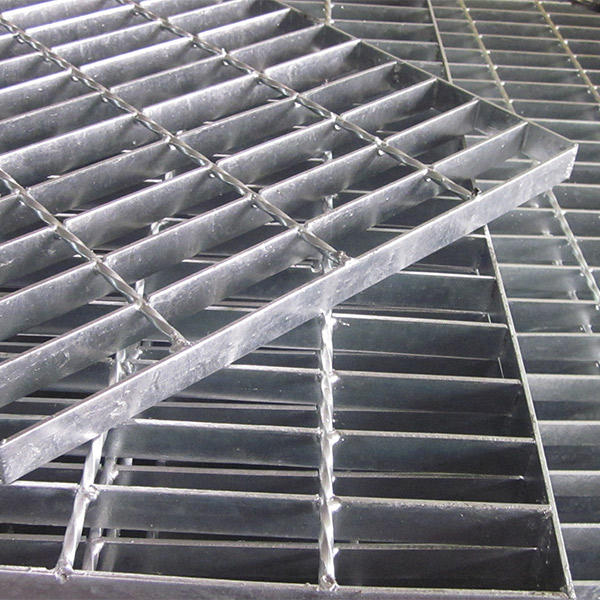

Surface treatment |

Untreated, Hot dip galvanized, Cold dip galvanized, Painted, Powder coated, or as customers’ requirement. |

|

Flat bar type |

Plain, Serrated (tooth-like), I bar (I section) |

|

Material standard |

Low carbon steel (CN: Q235, US: A36, UK: 43A) |

|

Galvanization standard |

CN: GB/T13912, US: ASTM (A123), UK: BS729 |

|

Steel grating standards |

A. China: YB/T4001-1998 |

|

B. USA: ANSI/NAAMM (MBG 531-88) |

|

|

C. UK: BS4592-1987 |

|

|

D. Australia: AS1657-1988 |

|

|

E: Japan: JJS |

Steel grating, also recognized as bar grating or metal grating, stands as an open grid assembly consisting of metal bars. Within this grid, the bearing bars, running unidirectionally, are strategically spaced through rigid attachment to cross bars running perpendicular to them or by bent connecting bars extending between these bearers. This design is specifically engineered to endure heavy loads while maintaining a minimal weight profile, enhancing its overall structural efficiency.

The versatility of steel grating spans across a multitude of industrial applications and environments. Primarily, it serves as an integral element in various settings such as floors, mezzanines, stair treads, and fencing systems. It is adeptly used in diverse contexts, including trench covers and maintenance platforms, offering support and stability while ensuring a safe environment.

The robust construction and high load-bearing capacity of steel grating make it an indispensable component in factories, workshops, and motor rooms, where its durability is crucial for withstanding regular heavy foot traffic and industrial equipment. Furthermore, its application extends to trolley channels, proving instrumental in facilitating the seamless movement of trolleys and heavy loading areas.

In industrial sectors such as boiler equipment and heavy machinery areas, steel grating's resilient nature plays a vital role in providing sturdy flooring and platforms, ensuring safety in high-risk and heavy-load environments. Its exceptional durability and corrosion resistance make it a reliable choice in such demanding settings, where structural integrity and safety are paramount.

The adaptability and reliability of steel grating, owing to its construction and load-bearing capacity, ensure it's an essential and versatile element across a diverse array of industries. Whether it's for industrial, commercial, or heavy-duty applications, steel grating remains an ideal choice, offering a balance between strength, durability, and minimal weight for various infrastructural needs.