Jul . 27, 2024 04:54 Back to list

Top Quality Cold Drawn Steel Bar Suppliers for All Your Industrial Needs Online

Understanding Cold Drawn Steel Bars The Role of Manufacturers in Quality Production

Cold drawn steel bars are an essential component in various industries, including construction, automotive, and manufacturing. These bars are known for their superior mechanical properties, which result from the cold drawing process where steel is pulled through a die to reduce its diameter and improve its surface finish. The significance of this manufacturing technique cannot be overstated as it directly impacts the performance and longevity of the final products.

The cold drawing process generally begins with hot-rolled steel as the raw material. The hot-rolled bars are then cooled to room temperature before undergoing the cold drawing process. During this phase, manufacturers employ precise control over the temperature and deformation, allowing for the creation of steel bars that are not only stronger but also exhibit tighter tolerance levels than their hot-rolled counterparts.

Understanding Cold Drawn Steel Bars The Role of Manufacturers in Quality Production

The role of manufacturers in producing cold drawn steel bars is crucial. They must adhere to strict quality control standards throughout the entire production process. This involves not only selecting high-quality raw materials but also implementing rigorous testing protocols to ensure that the finished product meets specific industry standards. Manufacturers often perform a variety of tests, including tensile tests, hardness tests, and dimensional inspections, to verify that their products can withstand the demands of their intended applications.

cold drawn steel bar manufacturer

Moreover, the expertise of manufacturers plays a pivotal role in the customization of cold drawn steel bars. Different industries may require specific dimensions, shapes, and mechanical properties, and skilled manufacturers can produce custom bar sizes and shapes to meet these various requirements. This flexibility is essential for businesses that rely on precise specifications to optimize their production processes.

Additionally, manufacturers of cold drawn steel bars are increasingly adopting advanced technologies and techniques to enhance productivity and efficiency. For instance, the integration of automation and computer-controlled machinery has significantly improved precision in the drawing process. Such technologies not only reduce production time but also minimize the potential for human error, ultimately leading to better quality assurance.

Sustainability is another critical consideration for manufacturers in this industry. As environmental concerns grow, many manufacturers are seeking ways to reduce waste and improve energy efficiency in their production processes. This can involve optimizing the use of resources, employing recycling practices, and investing in energy-saving technologies that not only benefit the environment but also reduce operational costs.

In conclusion, the manufacturing of cold drawn steel bars is a complex process that requires a high level of skill, technology, and commitment to quality. Manufacturers play an indispensable role in delivering products that meet the rigorous demands of various applications. By focusing on quality control, customization, advanced technology, and sustainability, these manufacturers ensure that cold drawn steel bars continue to be a vital resource across numerous industries. As the demand for high-performance materials grows, the relevance of cold drawn steel bar manufacturers will undoubtedly increase, shaping the future of material production and application.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

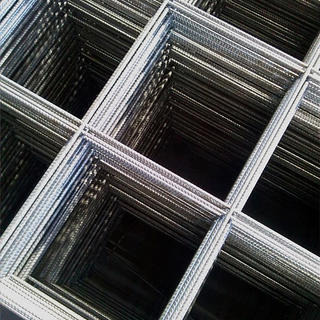

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025