Jul . 27, 2024 04:55 Back to list

High-Quality F72 Reinforcing Mesh Production from Leading Manufacturer for Construction Needs

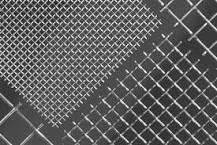

Exploring the F72% Reinforcing Mesh Factory Innovations in Construction Materials

In the ever-evolving landscape of construction, the demand for durable and high-quality materials is paramount. One such innovation in this field is the F72% reinforcing mesh, a product that has gained prominence for its structural integrity and versatility. This article delves into the intricacies of the F72% reinforcing mesh factory, shedding light on its manufacturing processes, applications, and the significance of this material in modern construction.

Understanding F72% Reinforcing Mesh

F72% reinforcing mesh is primarily composed of steel wire, strategically arranged to form a grid-like pattern. This mesh is designed to enhance the tensile strength of concrete structures, making it an essential component in a myriad of construction projects, from residential buildings to infrastructural developments. The designation “F72%” refers to the specific tensile strength and yield characteristics of the mesh, which meet the highest industry standards for safety and durability.

Manufacturing Process

The production of F72% reinforcing mesh takes place in state-of-the-art manufacturing facilities, often referred to as reinforcing mesh factories. These facilities are outfitted with advanced machinery capable of delivering precision and efficiency. The process typically begins with the sourcing of high-quality steel wires. These wires undergo stringent quality checks to ensure they meet the necessary specifications.

Once the raw materials are vetted, the wires are fed into specialized machines that cut and bend them into the desired dimensions. This stage is critical, as the configuration of the mesh can significantly influence its performance in real-world applications. The wires are then welded together at strategic intersections, forming a robust grid. This welding process employs high-frequency resistance welding technology, ensuring that the joints are strong and durable.

After the formation of the mesh, it undergoes a galvanization process to enhance its resistance to corrosion. By applying a protective zinc coating, the F72% reinforcing mesh can withstand exposure to harsh environmental conditions, making it ideal for outdoor and submerged applications.

f72 reinforcing mesh factory

Applications in Construction

The versatility of F72% reinforcing mesh is evident in its wide-ranging applications. It is commonly used in the reinforcement of concrete slabs, walls, and pavements. The mesh provides excellent support for structures undergoing various loads, thereby minimizing the risk of cracking and ensuring longevity.

In addition to traditional construction, F72% reinforcing mesh has found its place in roadways and bridges, where it plays a crucial role in distributing weight and enhancing structural resilience. Its use is also expanding into innovative construction methods, such as precast concrete elements and green building solutions, where sustainability plays a pivotal role.

Importance of Quality Control

Quality control is a cornerstone of the manufacturing process at the F72% reinforcing mesh factory. Each batch of mesh undergoes rigorous testing to ensure it meets the required specifications. This includes tensile tests, weld integrity checks, and surface treatment assessments. By adhering to these quality protocols, manufacturers can guarantee that their products will perform reliably in demanding construction environments.

Conclusion

The F72% reinforcing mesh factory represents a significant advancement in construction materials, showcasing how innovation can drive the industry forward. With its strong manufacturing process, versatility in applications, and unwavering focus on quality, F72% reinforcing mesh stands as a testament to the importance of robust materials in ensuring the safety and durability of structures. As the construction industry continues to adapt and grow, the role of high-performance materials like F72% reinforcing mesh will undoubtedly become even more critical in shaping our built environment.

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Thermal Resistance Eco-Friendly Airtight Seal

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.17,2025

-

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Premium Eco-Friendly Storage Solution|Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.16,2025