Dec . 03, 2024 14:40 Back to list

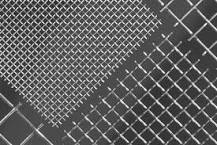

slabs reinforcement mesh manufacturer

The Importance of Slabs and Reinforcement Mesh in Modern Construction

In the realm of modern construction, ensuring structural integrity and longevity is paramount. One of the essential components that contribute to this is the use of slabs and reinforcement mesh. Manufacturing high-quality slabs and reinforcement mesh has become a cornerstone of the construction industry, as they play critical roles in providing stability and support for various structures.

Understanding Slabs and Reinforcement Mesh

Slabs are flat, horizontal surfaces that form the foundation or flooring of buildings, bridges, and other structures. They can be made from various materials, including concrete, which is favored for its durability and strength. Reinforcement mesh, commonly made from steel, is employed to enhance the tensile strength of concrete slabs. When concrete hardens, it can withstand compressive forces well but is weak against tension. By integrating reinforcement mesh, construction professionals ensure that slabs can endure stress and prevent cracking, ultimately enhancing the lifespan of the structure.

The Role of Reinforcement Mesh Manufacturers

The development and provision of high-quality reinforcement mesh are crucial for builders and contractors across the industry. Manufacturers of reinforcement mesh focus on precision engineering and adherence to safety standards to deliver products that meet the specific needs of various construction projects. The various types of reinforcement mesh, such as welded wire fabric and fiber mesh, cater to different applications and requirements, allowing for versatility in construction methodologies.

Quality Assurance in Production

slabs reinforcement mesh manufacturer

Reputable manufacturers adhere to strict quality control measures during the production process to ensure that their reinforcement mesh meets industry standards. This involves rigorous testing of materials to verify their strength, ductility, and resistance to corrosion. By utilizing advanced manufacturing techniques and equipment, manufacturers can produce mesh that offers optimal performance and reliability.

Innovations in Slab Design

In addition to producing high-strength reinforcement mesh, many manufacturers are at the forefront of innovation in slab design. New techniques such as post-tensioning and the use of composite materials are becoming increasingly common in the industry. These innovations allow for slimmer slabs, reduced weight, and improved load-bearing capacities, ultimately leading to more efficient construction practices and cost savings for builders.

Sustainability and Environmental Considerations

With a growing emphasis on sustainability in construction, many manufacturers are also focusing on eco-friendly practices. The use of recycled materials in the production of reinforcement mesh and slabs can significantly reduce the environmental impact of construction projects. Furthermore, designing structures that utilize materials efficiently and reduce waste reflects a commitment to sustainable development.

Conclusion

In conclusion, slabs and reinforcement mesh are indispensable components of modern construction, providing the strength and stability necessary for safe and durable structures. Manufacturers that specialize in these products play a vital role in the construction industry, ensuring that high-quality materials are available to meet the evolving needs of builders and architects. As we move forward, innovations in material science and a commitment to sustainability will continue to shape the future of slabs and reinforcement mesh, making them even more integral to the development of resilient infrastructure. Ultimately, investing in quality slabs and reinforcement mesh is an investment in the safety and longevity of our built environment, underscoring the importance of reliable manufacturers in this essential sector.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025