Dec . 03, 2024 14:40 Back to list

Top Manufacturers of Steel Square Bars for Construction and Industrial Use

The Growing Demand for Steel Square Bar Manufacturers

In the world of construction and manufacturing, steel square bars play a vital role due to their versatility and strength. As industries continue to expand, the demand for high-quality steel square bars has surged, leading to the emergence of various manufacturers specializing in their production. This article explores the significance of steel square bar manufacturers, the manufacturing process, and the factors driving demand in today’s market.

Importance of Steel Square Bars

Steel square bars are flat, rectangular bars that have a cross-section in the shape of a square. These bars are prevalent in a wide range of applications, from residential construction to industrial manufacturing. Their strength and durability make them ideal for structural components, support beams, frames, and even decorative elements. Given their uniform cross-section, they are also easily machinable, allowing for efficient customization to meet specific project requirements.

The Manufacturing Process

Steel square bar manufacturing involves several crucial steps, beginning with selecting high-quality raw materials. Most manufacturers use low-carbon steel, which provides excellent ductility and weldability, making it a preferred choice for various applications. The process typically starts with molten steel, which is cast into a semi-finished shape through processes like continuous casting.

Once the steel has cooled and solidified, it undergoes hot rolling or extruding to form a square shape. In hot rolling, the steel is heated above its recrystallization temperature and passed through rolling mills, effectively reducing its cross-sectional area while increasing its length. This process not only shapes the steel but also refines its internal structure, enhancing its mechanical properties.

After the initial shaping, the steel square bars may be subjected to additional processes like cold finishing, which improves dimensional accuracy and surface quality. Finally, bars may undergo treatments such as galvanizing or powder coating to provide corrosion resistance, further extending their lifespan and usability.

steel square bar manufacturers

Factors Driving Demand

Several factors contribute to the increasing demand for steel square bars and their manufacturers. Firstly, the ongoing urbanization and infrastructure development across the globe necessitate the use of durable materials like steel. As nations invest in building roads, bridges, and commercial buildings, the need for robust structural components continues to rise.

Moreover, the resurgence of manufacturing industries, particularly in emerging markets, has spurred a need for high-quality steel products. Industries such as automotive, aerospace, and machinery manufacturing rely heavily on steel square bars for various applications, from creating frames to forming intricate parts.

The construction sector is also a significant driver of demand. With the boom in residential and commercial construction projects, steel square bars find their use in a multitude of applications. Builders prefer them for their strength-to-weight ratio, making them easier to transport and install without compromising structural integrity.

Conclusion

The role of steel square bar manufacturers is indispensable in the current industrial landscape. As demand continues to rise, these manufacturers must adapt to changing market needs while maintaining quality standards. Emphasizing sustainability and technological improvements will also be crucial as industries strive to reduce their environmental impact.

In summary, the growth in demand for steel square bars is reflective of broader trends in construction and manufacturing. With continued advancements in production techniques and materials, steel square bar manufacturers are poised to meet the challenges of the future, contributing to the structural integrity and aesthetic appeal of various projects around the globe. As such, the steel square bar industry remains an essential pillar of modern infrastructure and manufacturing.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

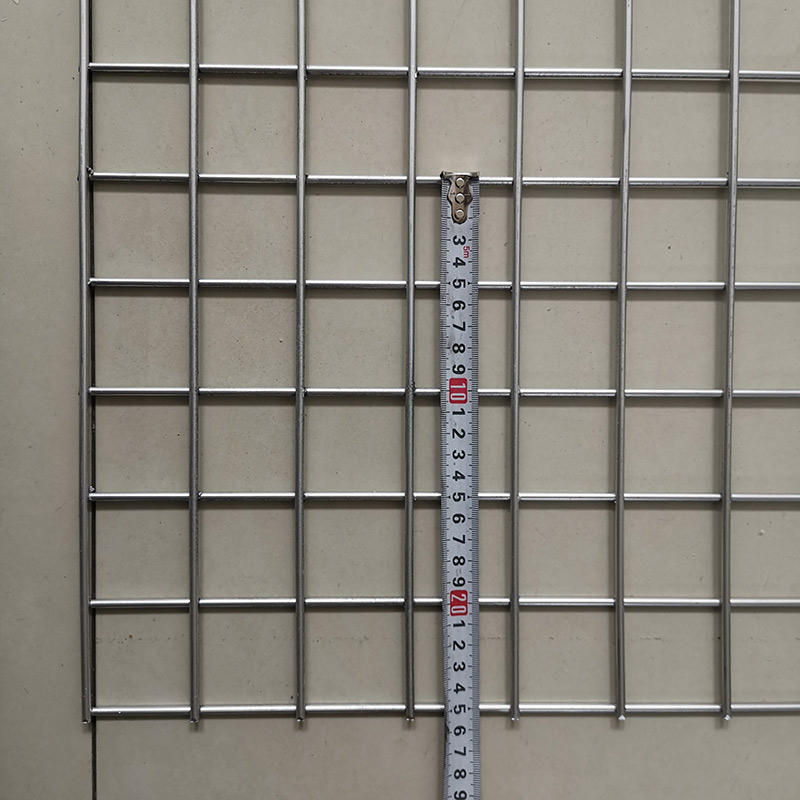

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025