Dec . 06, 2024 08:06 Back to list

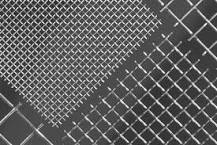

serrated stainless steel grating factories

Exploring Serrated Stainless Steel Grating Factories A Comprehensive Overview

In today's industrial landscape, the demand for durable, versatile, and reliable materials has led to the increased use of stainless steel grating. Among the various types available, serrated stainless steel grating stands out for its unique features that provide enhanced safety and functionality. As industries seek out quality materials, understanding the workings of serrated stainless steel grating factories becomes crucial.

What is Serrated Stainless Steel Grating?

Serrated stainless steel grating is a type of flooring material made from stainless steel, designed with serrated (or notched) edges. This design increases traction, making it safer for workers to walk on, especially in environments where water, oil, or other substances might create slippery conditions. The serrations create additional friction, significantly reducing the risk of slips and falls, making it an indispensable element in sectors such as manufacturing, food processing, oil and gas, and construction.

The Manufacturing Process

The production of serrated stainless steel grating involves several critical stages, starting with the selection of high-quality raw materials. Stainless steel's corrosion-resistant properties make it an ideal choice for grating applications exposed to harsh environmental conditions. Factories specializing in serrated stainless steel grating utilize different grades of stainless steel, such as 304 and 316, depending on the specific requirements of their clients.

Once the material is selected, the manufacturing process typically follows these steps

1. Cutting and Forming Large sheets of stainless steel are cut into manageable sizes. The factory uses advanced cutting technology to ensure precision. This stage may also involve forming the raw material into the desired shapes through bending or rolling equipment.

2. Serration Creation Serrated edges are created either through a dedicated serration process or by using CNC machines capable of delivering precise notches. This is a crucial step that determines the overall functionality and safety of the grating.

3. Welding and Assembly Once the individual pieces are serrated, they are assembled into larger grating panels. Welding is performed with high-quality techniques to ensure that the joints are strong and durable. This step is vital for maintaining the structural integrity of the grating.

4. Finishing and Treatment The final stage involves surface finishing processes, such as polishing or passivation, to enhance corrosion resistance and aesthetic appeal. Factories often conduct thorough quality control inspections at this stage to ensure that every panel meets industry standards.

serrated stainless steel grating factories

Benefits of Utilizing Serrated Stainless Steel Grating

Serrated stainless steel grating offers numerous advantages. Its robust nature makes it suitable for high-load applications, effectively supporting heavy machinery and pedestrian traffic. Additionally, the corrosion-resistant properties of stainless steel ensure longevity, reducing the need for frequent replacements, which translates to lower maintenance costs.

Moreover, the versatility of serrated stainless steel grating means it can be used in various applications, including walkways, platforms, drainage covers, and more. Its design can also provide better visibility for workers, as the unique serrated pattern allows for improved light diffusion, minimizing the chances of accidents in low-light conditions.

Choosing the Right Factory

When selecting a serrated stainless steel grating factory, several factors should be considered

- Reputation and Experience Look for factories with a proven track record and extensive experience in producing high-quality grating. Customer reviews and case studies can provide insights into the factory's reliability and service quality.

- Quality Standards Ensure that the factory adheres to international quality standards and certifications. This is crucial to guarantee durability and safety in the final products.

- Customization Options Many industries have specific requirements for grating sizes, materials, and load capacities. Choose a factory that offers customization to meet these unique needs.

- Technical Support A responsive factory that provides technical support and product advice can be invaluable, especially when navigating complex projects.

Conclusion

Serrated stainless steel grating factories play a vital role in various industries by producing essential components that enhance safety and efficiency. Understanding their manufacturing processes, benefits, and how to choose the right one is crucial for businesses seeking to optimize their operations while ensuring safety and durability. As industries continue to evolve, the importance of high-quality materials like serrated stainless steel grating will only increase, making it a smart investment for any industrial operation.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025