Dec . 06, 2024 08:20 Back to list

Manufacturers of High-Quality Welded Steel Mesh Panels for Various Applications

Understanding Welded Steel Mesh Panels A Comprehensive Guide to Manufacturers

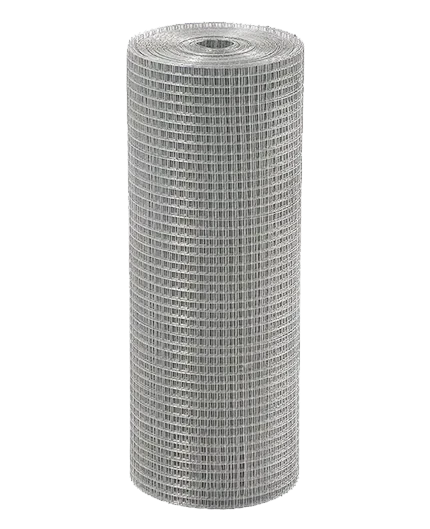

Welded steel mesh panels have become an indispensable component in various industrial and construction applications. They are known for their durability, strength, and versatility, making them a preferred choice for many builders and contractors. This article aims to provide insights into the production, benefits, and key considerations when selecting welded steel mesh panel manufacturers.

What are Welded Steel Mesh Panels?

Welded steel mesh panels are fabricated from intersecting steel wires that are welded together at their junctions. Typically, they come in various gauge sizes and are available in different mesh designs, ranging from small openings for fencing to larger gaps for supporting structures. These panels are widely used for applications such as reinforced concrete, agricultural fencing, animal enclosures, and security barriers. Their strength and structural integrity make them a reliable choice for both residential and industrial purposes.

The Importance of Quality Manufacturing

When it comes to welded steel mesh panels, the quality of the manufacturing process directly affects the performance and longevity of the product. Reliable manufacturers adhere to strict production standards and utilize high-grade materials to ensure that the panels can withstand harsh environments and heavy loads. Some key factors to consider when evaluating manufacturers include

1. Materials The quality of steel used in the welding process is crucial. Look for manufacturers that source their steel from reputable suppliers and ensure it meets industry standards, such as ASTM or EN certifications.

2. Welding Process The method used to weld the wires together plays a significant role in the strength of the mesh panels. High-quality manufacturers typically use robotic welding techniques for precision, consistency, and reliability. These processes reduce the risk of weaknesses that can occur in less-controlled environments.

3. Finishing Options The finishing touches on welded steel mesh panels can enhance their durability and aesthetic appeal. Common finishes include hot-dip galvanization, powder coating, and PVC coating. These treatments can help protect the panels from corrosion, rust, and environmental damage.

welded steel mesh panel manufacturers

4. Customization Different projects have different requirements. Leading manufacturers often offer customization options, allowing clients to specify mesh size, wire gauge, and panel dimensions to meet unique project needs.

Advantages of Choosing Reputable Manufacturers

Selecting a trusted and established welded steel mesh panel manufacturer can significantly benefit your project. Here are several advantages of working with reputable manufacturers

1. Consistent Quality Established manufacturers have a reputation to uphold. They employ quality control measures, ensuring that every batch of panels meets required specifications. This consistency in quality minimizes potential issues during installation and long-term use.

2. Technical Support Reliable manufacturers often provide expert guidance on product applications, installation techniques, and maintenance. Their support can be invaluable, especially for complex projects where the right specifications are critical.

3. Timely Delivery Established manufacturers typically understand the importance of timelines in construction projects. They are more likely to adhere to delivery schedules, which helps keep your project on track.

4. Warranty and Support Many reputable manufacturers offer warranties on their products, providing an added layer of security in case of defects or issues. This assurance is essential for clients looking to invest in long-term projects.

Conclusion

Welded steel mesh panels are vital components in modern construction and industrial applications. Understanding the significance of selecting a high-quality manufacturer can save you time, money, and ensure the success of your projects. When seeking welded steel mesh panels, always consider factors like material quality, welding techniques, and the manufacturer’s reputation. By doing so, you'll be well-equipped to make informed choices that enhance the safety and integrity of your constructions. As the industry continues to evolve, staying updated on the latest manufacturing techniques and offerings will further empower your decision-making process.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025