Jul . 25, 2024 06:42 Back to list

Manufacturers Offering Various Sizes of Standard Welded Wire Mesh for Diverse Applications

Understanding Standard Welded Wire Mesh Sizes A Guide for Manufacturers

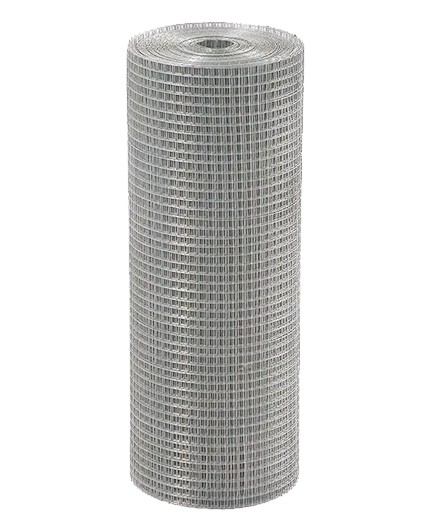

Welded wire mesh, a versatile construction material, is widely used across various industries for a range of applications, including construction, agriculture, and reinforcement. The mesh is constructed from steel wires that are welded at their intersections, creating a robust and durable product. For manufacturers, understanding the standard sizes of welded wire mesh is crucial for meeting customer demands and ensuring quality control.

What is Welded Wire Mesh?

Welded wire mesh consists of a grid of wires that are welded together at regular intervals. This process not only enhances the strength of the material but also provides a uniform and consistent product. The mesh is available in various materials, including galvanized steel, stainless steel, and PVC-coated wire, making it suitable for both indoor and outdoor applications. Common uses include animal enclosures, fencing, construction reinforcement, and even decorative projects.

Standard Sizes of Welded Wire Mesh

One of the key aspects manufacturers should consider is the standard sizes of welded wire mesh. These sizes primarily refer to the spacing between the wires, the diameter of the wires, and the overall dimensions of the mesh sheets or rolls. Typically, welded wire mesh is available in various configurations, such as

1. Mesh Opening Size The size of the openings can vary significantly, usually ranging from 1 inch to 6 inches. Common sizes include 2x2 inches, 4x4 inches, and 6x6 inches, which are frequently used in construction and agricultural applications.

2. Wire Diameter The diameter of the wire can also vary, with standard sizes typically ranging from 14 gauge to 6 gauge. Thicker wires (lower gauge numbers) provide more strength and durability, making them suitable for heavy-duty applications.

3. Sheet Dimensions Welded wire mesh is generally available in sheets (e.g., 4x8 feet) or rolls, allowing manufacturers to choose the most appropriate format for their needs.

standard welded wire mesh size manufacturers

Factors to Consider When Choosing Mesh Size

When selecting the appropriate standard welded wire mesh size, manufacturers should consider several factors

1. Application Requirements Different applications have different requirements; for instance, fencing for livestock may require stronger, thicker wire, while a wire mesh for concrete reinforcement may have different specifications.

2. Load-Bearing Capacity The load-bearing requirements of the project will influence the choice of mesh. Thicker wires and smaller openings provide greater load-bearing capacity.

3. Environmental Conditions For outdoor applications, corrosion resistance is essential. Galvanized or stainless steel options are preferable for environments prone to moisture and corrosive elements.

4. Aesthetic Preferences For decorative projects, manufacturers may also need to consider the aesthetic aspects of the welded wire mesh, choosing sizes and designs that complement the overall look of the project.

Conclusion

Understanding the standard sizes of welded wire mesh is essential for manufacturers aiming to deliver quality products that meet customer needs. By considering factors such as application requirements, load-bearing capacity, environmental conditions, and aesthetic preferences, manufacturers can make informed decisions about the sizes and specifications of welded wire mesh. This awareness not only aids in product selection but also enhances customer satisfaction, leading to long-term business success in the competitive market of welded wire mesh manufacturing.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025