Jul . 25, 2024 06:43 Back to list

High-Quality Galvanized Steel Grating Manufacturing for Industrial and Commercial Applications Worldwide

The Importance of Galvanized Steel Grating in Modern Industry

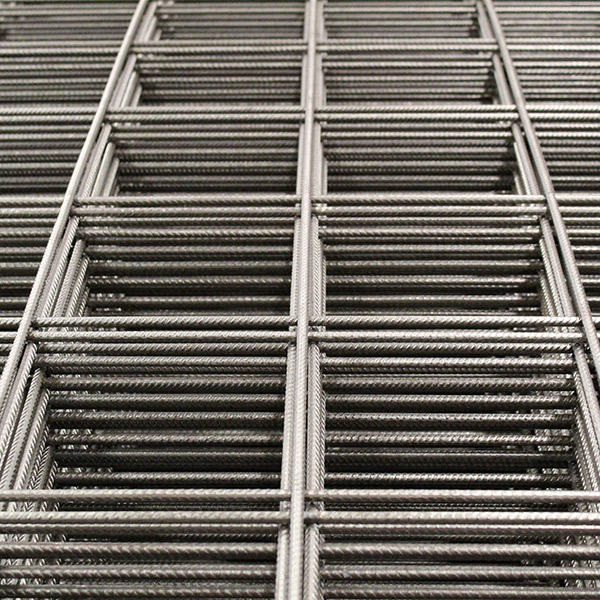

Galvanized steel grating is an essential material in various industrial applications, known for its strength, durability, and resistance to corrosion. This versatile product is fabricated from a set of twisted steel bars, which are then coated with a layer of zinc to protect them from environmental factors. The galvanization process extends the life of the steel, making it an ideal choice for various settings, including manufacturing plants, commercial facilities, and outdoor environments.

The Importance of Galvanized Steel Grating in Modern Industry

Another significant benefit of galvanized steel grating is its versatility. Steel grating is available in various shapes, sizes, and configurations, making it adaptable to a wide range of applications. It can be customized to meet specific load-bearing requirements or fitting particular installation dimensions. Common uses include floor grating in factories, trench covers, drainage covers, and stair treads in industrial plants. The open design of steel grating allows for excellent drainage and ventilation, making it suitable for environments where moisture buildup could lead to safety hazards.

galvanzied steel grating factory

Safety is a critical concern in any industrial setting. Galvanized steel grating helps to enhance workplace safety by providing a slip-resistant surface, reducing the risk of accidents and falls. The serrated or galvanized finish offers improved traction, which is especially important in areas that may become wet or oily. Furthermore, the visibility provided by the open design helps workers identify potential hazards, contributing to a safer working environment.

The cost-effectiveness of galvanized steel grating is another factor that makes it a preferred choice in many industries. While the initial investment may be higher than for some alternative materials, the long lifespan and low maintenance requirements of galvanized grating translate to reduced total costs over time. Regular maintenance is simplified, as the zinc coating requires minimal upkeep compared to uncoated steel, which would demand frequent inspections and potential replacements due to rust damage.

In addition to practical benefits, galvanized steel grating also supports sustainability initiatives within industries. By opting for a durable material like galvanized steel, companies can reduce waste and the need for frequent replacements, which aligns with environmental goals. The recyclability of steel further emphasizes its eco-friendliness, as it can be recycled multiple times without losing its inherent properties.

In conclusion, galvanized steel grating is an invaluable asset in various industrial applications due to its durability, versatility, safety features, cost-effectiveness, and eco-friendly characteristics. As industries continue to prioritize safety and sustainability, the demand for high-quality galvanized steel grating is expected to rise. Companies investing in this robust material can enhance their operational efficiency while ensuring a safe working environment for their employees. Whether in manufacturing, construction, or any industrial sector, the importance of galvanized steel grating cannot be overstated.

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Thermal Resistance Eco-Friendly Airtight Seal

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.17,2025

-

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Premium Eco-Friendly Storage Solution|Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.16,2025