Aug . 07, 2024 17:30 Back to list

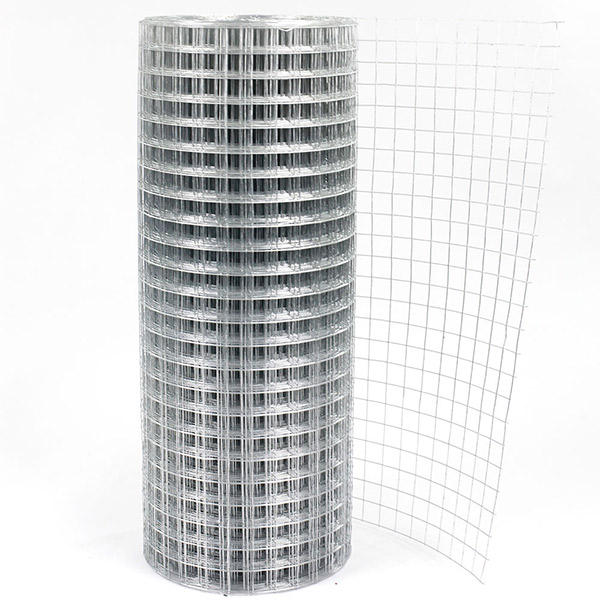

Leading Manufacturer of Galvanized Reinforced Concrete Nets for Enhanced Construction Solutions

Galvanized Reinforced Concrete Net Manufacturer Ensuring Durability and Strength

In the world of construction and civil engineering, the materials we choose can make a significant difference in the strength, durability, and longevity of structures. One such material that has gained immense popularity is the galvanized reinforced concrete net. As a manufacturer of these nets, we play a critical role in ensuring that construction projects benefit from innovative, reliable, and sustainable products.

What is Galvanized Reinforced Concrete Net?

Galvanized reinforced concrete nets are a combination of steel reinforcement bars (rebar) and galvanized wire mesh. This unique composition provides several advantages over traditional concrete reinforcements. The process of galvanization involves coating the steel with a layer of zinc, which protects it from rust and corrosion. This is particularly beneficial for structures exposed to harsh environmental conditions, such as moisture, chemicals, and temperature fluctuations.

The concrete net itself serves as a crucial structural element, enhancing the tensile strength and overall load-bearing capacity of concrete. It maintains the integrity of the material by preventing cracking and shifting, particularly in areas subject to significant stress or movement.

Benefits of Galvanized Reinforced Concrete Nets

1. Corrosion Resistance The galvanization process ensures a longer lifespan for the steel components of the net. Unlike traditional uncoated steel, galvanized nets can withstand corrosion for many years, making them an ideal choice for bridge construction, roadways, and other external structures.

2. Enhanced Load-Bearing Capacity Galvanized reinforced concrete nets contribute to improved load distribution throughout the concrete, which is vital for structures that bear heavy weights or are subject to heavy traffic.

galvanized reinforced concrete net manufacturer

3. Versatile Applications These nets are suitable for a diverse range of applications, including but not limited to foundations, walls, floors, and even precast elements. They can be custom-designed to meet the specific requirements of any project.

4. Cost-Effectiveness While the initial investment might be higher than alternative materials, the long-term savings on maintenance, repairs, and replacement make galvanized reinforced concrete nets a cost-effective solution.

5. Sustainability In today's world, sustainability is a priority. The durable nature of galvanized nets means less frequent replacements and reduced waste. Moreover, the recyclability of steel makes it an excellent choice for environmentally conscious construction practices.

The Role of Manufacturers

As a manufacturer of galvanized reinforced concrete nets, our responsibility extends beyond just producing the materials. We prioritize research and development to keep pace with advancements in technology and construction techniques. Quality control is paramount; we ensure that every net produced meets industry standards for strength, durability, and safety.

Moreover, we understand that collaboration with architects, engineers, and contractors is essential. By working closely with our clients, we can develop customized solutions that meet specific project needs, thus ensuring optimal performance.

Conclusion

In summary, galvanized reinforced concrete nets are becoming indispensable in modern construction due to their strength, durability, and versatility. As manufacturers, we are committed to providing high-quality materials that not only enhance the safety and lifespan of structures but also contribute to a more sustainable future. By embracing innovation and maintaining strict quality standards, we aim to lead the way in this essential segment of the construction industry, ensuring that each project is completed successfully with our reliable products.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025