Aug . 07, 2024 17:50 Back to list

Manufacturers of Galvanized Wire Mesh for Brick Masonry and Construction Applications

The Role of Galvanized Brick Coil Wire Mesh in Modern Masonry Construction

In the ever-evolving world of construction, the selection of materials plays a crucial role in determining the durability, efficiency, and aesthetics of a building. One such material that has garnered significant attention in masonry construction is the galvanized brick coil wire mesh. This innovative product combines strength, flexibility, and corrosion resistance, making it an ideal choice for modern construction needs.

Understanding Galvanized Brick Coil Wire Mesh

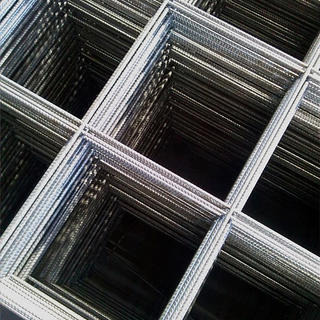

Galvanized wire mesh is created by coating steel wire with a layer of zinc, providing enhanced resistance against rust and corrosion. This makes it particularly suitable for applications exposed to harsh environmental conditions. In the context of masonry, galvanized wire mesh is often used to support brick and stone structures, providing a robust framework that helps to maintain the integrity of the masonry over time.

The coil form of the wire mesh offers convenience in handling and application. When unrolled, it can cover extensive areas, allowing for faster installation and reducing the need for multiple seams. This is especially beneficial in large-scale construction projects, where time efficiency is a top priority. Moreover, the flexibility of the mesh allows it to be easily shaped to fit various architectural designs, catering to both functional and aesthetic requirements.

Advantages of Using Galvanized Brick Coil Wire Mesh

1. Corrosion Resistance The zinc coating on galvanized wire mesh significantly prolongs its lifespan. Unlike standard steel, which can quickly rust when exposed to moisture, galvanized wire maintains its integrity even in damp environments. This is particularly important in masonry work, where moisture infiltration can lead to structural degradation over time.

galvanized brick coil wire mesh masonry factories

2. Strength and Stability Galvanized wire mesh provides excellent tensile strength, helping to distribute loads evenly across the masonry structure. This reinforcement is vital in preventing cracks and ensuring the overall stability of walls, especially in areas prone to seismic activity.

3. Versatility The varied applications of galvanized brick coil wire mesh extend beyond traditional masonry. It can be used in fences, partitions, and even as a base for plastering. This multipurpose nature empowers builders and architects to incorporate it into a wide range of construction scenarios.

4. Cost-Effectiveness Although the initial investment might be higher than that of traditional materials, the longevity and reduced maintenance costs associated with galvanized mesh can lead to significant savings over time. The decreased need for repairs and replacements results in a better return on investment for project stakeholders.

Environmental Considerations

As sustainability becomes a focal point in construction, the use of galvanized wire mesh aligns with eco-friendly practices. The longevity of the material reduces waste, and since it's made from recyclable steel, it contributes positively to the circular economy. Additionally, its efficiency in maintaining structural integrity can lessen the need for extra materials, promoting resource conservation.

Conclusion

Galvanized brick coil wire mesh is revolutionizing the way masonry is approached in modern construction. Its unique properties—such as corrosion resistance, strength, versatility, and cost-effectiveness—make it an essential component in building resilient structures. As the industry continues to prioritize sustainability and efficiency, the adoption of advanced materials like galvanized wire mesh will likely become more prevalent, paving the way for innovative construction practices that meet the demands of today's complex architectural landscapes. As builders and architects embrace these advancements, the future of masonry looks brighter and more resilient than ever before.

-

Chain Link Fence: Comprehensive Guide to Features, Applications, and Specifications - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.08,2025

-

100x100cm Square Reinforcing Mesh - Direct Factory Supply

NewsAug.08,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Chain Link Fence - Durable, Versatile Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Chain Link Fence: Durable, Versatile, Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Galvanized Steel Fence Factory: Durable & Rust-Proof Fencing

NewsAug.07,2025