Jul . 27, 2024 04:55 Back to list

Exploring Leading Manufacturers of Reinforcement Mesh A193 for Construction and Industrial Applications

Reinforcement Mesh A193 Factories An Overview

Reinforcement mesh, often referred to as wire mesh or rebar mesh, plays a crucial role in construction and structural engineering. Among the various grades and types of reinforcement mesh available in the market, A193 is noteworthy due to its high strength and versatility. This article will explore the significance of Reinforcement Mesh A193 factories, their production processes, and the importance of quality standards in manufacturing.

Importance of Reinforcement Mesh A193

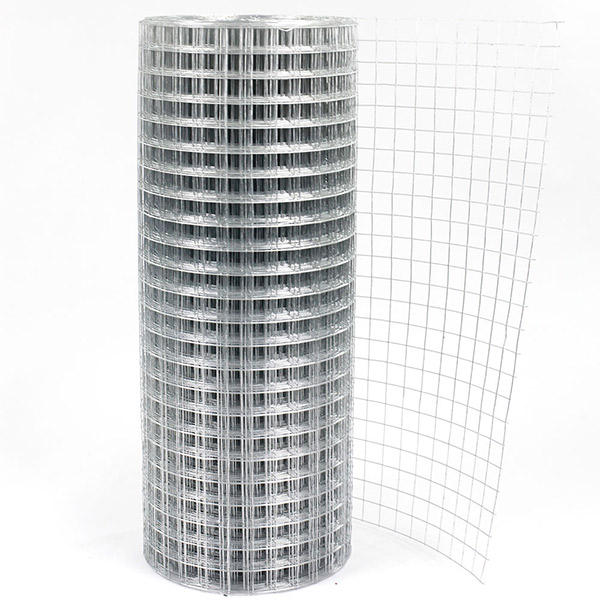

Reinforcement mesh A193 is primarily used in concrete construction to enhance the strength and stability of structures. It is made from high-quality steel wires that are welded together in a grid pattern. This mesh is designed to bear the tensile loads that concrete alone cannot handle, thereby preventing cracking and extending the lifespan of buildings, pavements, and bridges. The widespread application of A193 mesh in residential, commercial, and industrial constructions underscores its importance in modern architecture.

Production Process in Factories

The production of Reinforcement Mesh A193 involves several critical steps. The process begins with the selection of raw materials, which are usually high-tensile steel wires. These wires are subjected to rigorous testing to ensure they meet the required mechanical properties defined by various standards. Once the materials are verified, they undergo wire drawing, a process that reduces the diameter of the wire while increasing its length and strength.

reinforcement mesh a193 factories

Next, the wires are arranged in a grid pattern and are then welded at the intersections. This welding process can be performed using various techniques, including resistance welding and laser welding, depending on the specifications and requirements of the project. After welding, the mesh is cut to size and is often treated with coatings for enhanced durability, such as galvanization to prevent corrosion.

Quality control is a crucial aspect of manufacturing reinforcement mesh. Factories must adhere to stringent quality standards, often guided by international norms such as ASTM and ISO certifications. Regular testing for tensile strength, elongation, and ductility is essential to ensure the product’s reliability and safety. These measures not only assure product quality but also boost the confidence of contractors and engineers who utilize A193 mesh in their projects.

Environmental Considerations

In addition to technological advancements, many Reinforcement Mesh A193 factories are shifting towards sustainable practices. The steel industry is one of the most energy-intensive sectors; thus, implementing energy-efficient processes and recycling scrap materials can significantly reduce the environmental impact. Factories are exploring innovative methods to optimize resource use, lower emissions, and manage waste effectively. By adopting these practices, manufacturers can contribute to sustainable construction efforts while bolstering their reputation in the market.

Conclusion

Reinforcement Mesh A193 factories are pivotal in the construction industry, providing essential products that ensure the safety and longevity of structures. The meticulous production processes, rigorous quality control, and commitment to sustainability highlight the importance of these factories in modern architecture. As the demand for high-quality construction materials continues to rise, the role of Reinforcement Mesh A193 in ensuring structural integrity remains indispensable. By continually innovating and adhering to high standards, these factories will not only meet current industry demands but also pave the way for a more sustainable future in construction.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025