Oct . 19, 2024 05:09 Back to list

china cold drawn flat steel

The Rise of Cold Drawn Flat Steel in China

Cold drawn flat steel has emerged as a significant product within the global steel industry, particularly in China, where it is rapidly gaining prominence. This innovative manufacturing process involves drawing steel at room temperature through a die, which not only refines its dimensions but also enhances its mechanical properties. The precision and quality of cold drawn flat steel make it a preferred choice for various applications, including automotive, construction, and machinery, thus reinforcing its importance in the competitive steel market.

The Rise of Cold Drawn Flat Steel in China

One of the key advantages of cold drawn flat steel is its superior mechanical properties. The cold drawing process leads to improvements in yield strength, tensile strength, and surface finish. This makes it particularly suited for applications that require high performance and durability. Industries such as automotive manufacturing, where precision and reliability are crucial, have increasingly adopted cold drawn flat steel components for their production lines. As a result, many Chinese manufacturers have begun to specialize in producing high-quality cold drawn products to meet the evolving demands of the automotive sector.

china cold drawn flat steel

Furthermore, the construction industry in China has also benefited from the use of cold drawn flat steel. This material is employed in various structural applications, including beams, frames, and reinforcements. The enhanced strength and dimensional accuracy of cold drawn flat steel contribute to safer and more reliable construction practices. As China's urbanization continues to accelerate, the demand for high-quality construction materials will likely rise, further propelling the cold drawn flat steel market.

Additionally, the global push towards sustainability and energy efficiency is fueling the growth of cold drawn flat steel. Manufacturers are increasingly prioritizing environmentally friendly practices, and cold drawn processes can be optimized to reduce waste and energy consumption. As international standards for sustainable manufacturing become stricter, China's cold drawn steel producers are well-positioned to comply with these regulations, gaining a competitive edge in the global market.

While the future looks promising for cold drawn flat steel in China, challenges remain. The industry must navigate fluctuating raw material costs, stringent environmental regulations, and intense competition from both domestic and international producers. Nevertheless, with continuous innovation and adaptation, China’s cold drawn flat steel sector is set to play a pivotal role in the global steel industry.

In conclusion, the rise of cold drawn flat steel in China represents a dynamic shift in the country's manufacturing landscape. As it meets the demands of various industries through high-quality and sustainable production methods, cold drawn flat steel is poised to make significant contributions to both domestic and global markets. The future of this product looks bright, driven by technological advancements and an unwavering commitment to quality.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

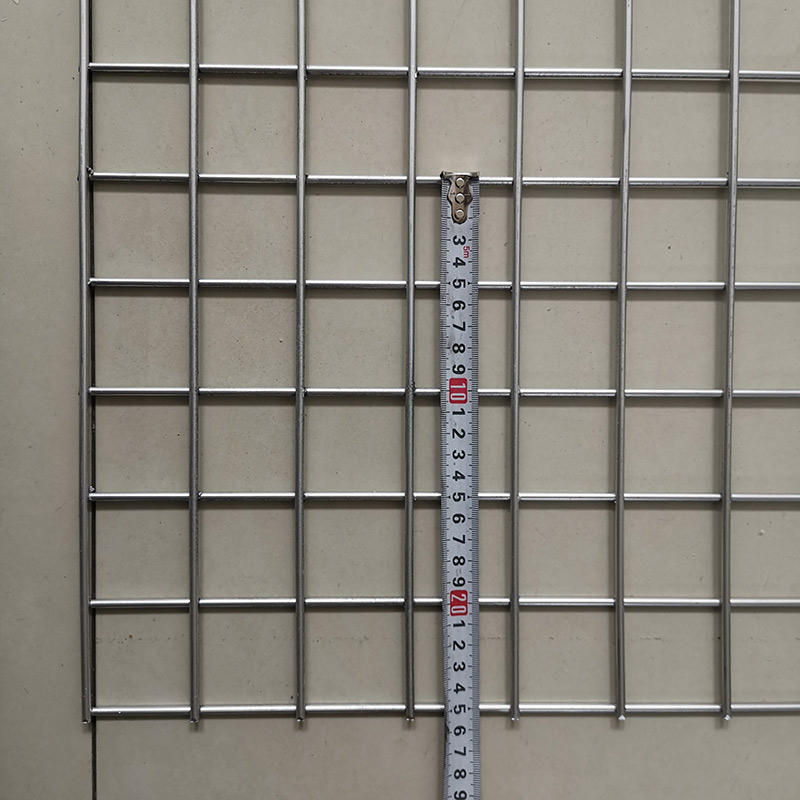

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025