Oct . 19, 2024 05:23 Back to list

reinforcement weld wire mesh supplier

The Importance of Reinforcement Weld Wire Mesh in Construction Choosing the Right Supplier

In the world of construction, the materials used can significantly impact the safety, durability, and overall performance of a structure. One such critical component is reinforcement weld wire mesh. This specialized mesh, often made from high-quality steel, plays a pivotal role in reinforcing concrete structures, ensuring that they can withstand various loads and pressures throughout their lifespan. Choosing the right supplier for reinforcement weld wire mesh is essential, and here we explore its significance and how to select a reliable supplier.

Understanding Reinforcement Weld Wire Mesh

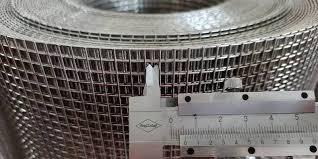

Reinforcement weld wire mesh is a grid-like structure created by welding intersecting steel wires together at various intervals. The mesh provides additional tensile strength to concrete, which is typically strong in compression but weak in tension. By incorporating this mesh into concrete slabs, walls, and other elements, engineers can enhance the integrity and longevity of the structures.

The applications of reinforcement weld wire mesh are diverse. It is commonly used in foundations, floors, bridge decks, and precast concrete products. With the increasing demand for durable and resilient structures in urban environments, the use of this mesh has become more prevalent.

Why Choosing the Right Supplier Matters

1. Quality Assurance The quality of reinforcement weld wire mesh directly affects the strength and stability of the concrete structure. A reliable supplier should provide products compliant with industry standards and certifications. This ensures that the materials can withstand the expected loads and environmental conditions over time.

reinforcement weld wire mesh supplier

2. Material Durability Not all wire meshes are created equal. Suppliers who offer high tensile strength and corrosion-resistant materials will provide better long-term performance. The use of galvanized steel or polymer-coated meshes can significantly extend the lifespan of the reinforcement.

3. Customization Options Depending on the specific requirements of a project, customized sizes, shapes, and configurations of weld wire mesh may be necessary. A reputable supplier will have the capability to offer customized solutions tailored to individual project needs.

4. Competitive Pricing While cost should not be the sole factor in supplier selection, it is important to compare pricing to ensure you are getting value for your investment. A good supplier will provide transparent pricing with no hidden costs and offer bulk purchase discounts.

5. Timely Delivery Construction projects operate on tight schedules, and delays in material supply can lead to increased costs and project overruns. Choosing a supplier with a proven track record of timely delivery is crucial to keeping your project on track.

6. Customer Support From initial inquiries to post-purchase support, having access to knowledgeable customer service can make a significant difference. A supplier that offers expert advice on product selection and installation can greatly enhance the overall project efficiency.

Conclusion

In summary, reinforcement weld wire mesh is an indispensable component in modern construction, providing essential support and stability to concrete structures. Selecting the right supplier is crucial to ensure that the mesh meets quality standards and provides the intended durability and strength. By focusing on quality assurance, material durability, customization options, competitive pricing, timely delivery, and customer support, contractors and builders can make informed decisions that contribute to the success of their projects. Ultimately, a reliable supplier not only helps to ensure structural integrity but also adds value to the overall project execution.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025