Jan . 16, 2025 04:18 Back to list

Twisted Square Bar

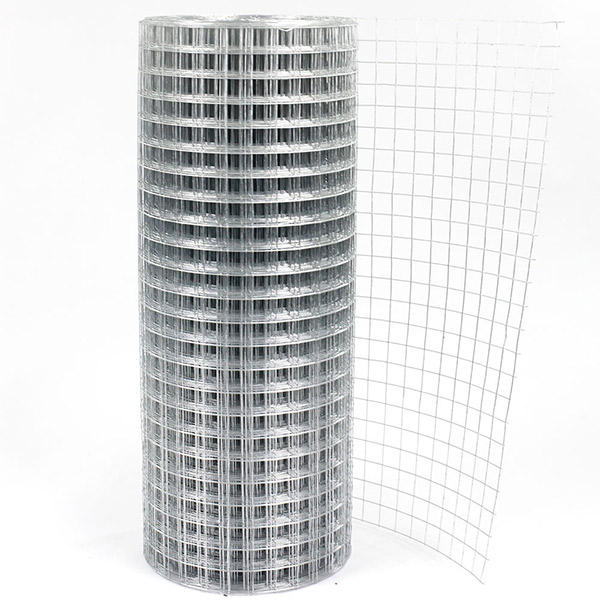

Reinforcing mesh, particularly the 100x100 variant, is rapidly becoming an essential component in modern construction projects. Its structural integrity and flexibility make it a go-to solution for enhancing the strength and longevity of concrete structures. This article will delve into the mechanics and benefits of 100x100 reinforcing mesh, providing industry insights and affirming its place as a critical material in contemporary infrastructure.

Reflecting on real-world experiences, construction professionals consistently acknowledge the transformative impact of using robust materials like 100x100 reinforcing mesh. Case studies frequently highlight projects where its implementation significantly extended the lifespan of structures, reduced maintenance costs, and enhanced overall safety. These outcomes not only provide peace of mind to stakeholders but also demonstrate tangible returns on investment through improved asset durability. Moreover, the environmental benefits should not be overlooked. By enhancing longevity and reducing the need for frequent repairs and reconstructions, the 100x100 reinforcing mesh contributes to sustainable building practices. It helps in minimizing resource wastage and carbon footprints associated with construction and demolition activities. For those seeking a reliable and authoritative material in slab and wall reinforcement, the 100x100 reinforcing mesh offers an optimal solution that fuses traditional engineering principles with modern requirements for efficiency and sustainability. Its practical application is extensive, earning it the trust of professionals who constantly pursue excellence in building performance. In conclusion, the 100x100 reinforcing mesh stands as a testament to the advancements in construction technology, marrying ease of use with exceptional strength and reliability. Whether one views it through the lens of experience, where countless successful projects bear its mark, or through the eyes of an expert understanding its fundamental engineering benefits, this mesh is indisputably a cornerstone of contemporary construction. Its authoritative presence in the market, backed by stringent compliance with safety standards, establishes its trustworthiness, ensuring that new buildings aren’t just constructed, but invested in for a future of stability and durability.

Reflecting on real-world experiences, construction professionals consistently acknowledge the transformative impact of using robust materials like 100x100 reinforcing mesh. Case studies frequently highlight projects where its implementation significantly extended the lifespan of structures, reduced maintenance costs, and enhanced overall safety. These outcomes not only provide peace of mind to stakeholders but also demonstrate tangible returns on investment through improved asset durability. Moreover, the environmental benefits should not be overlooked. By enhancing longevity and reducing the need for frequent repairs and reconstructions, the 100x100 reinforcing mesh contributes to sustainable building practices. It helps in minimizing resource wastage and carbon footprints associated with construction and demolition activities. For those seeking a reliable and authoritative material in slab and wall reinforcement, the 100x100 reinforcing mesh offers an optimal solution that fuses traditional engineering principles with modern requirements for efficiency and sustainability. Its practical application is extensive, earning it the trust of professionals who constantly pursue excellence in building performance. In conclusion, the 100x100 reinforcing mesh stands as a testament to the advancements in construction technology, marrying ease of use with exceptional strength and reliability. Whether one views it through the lens of experience, where countless successful projects bear its mark, or through the eyes of an expert understanding its fundamental engineering benefits, this mesh is indisputably a cornerstone of contemporary construction. Its authoritative presence in the market, backed by stringent compliance with safety standards, establishes its trustworthiness, ensuring that new buildings aren’t just constructed, but invested in for a future of stability and durability.

Next:

Latest news

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Eco-Friendly, Heat-Resistant, Durable

NewsAug.17,2025