Aug . 04, 2025 02:40 Back to list

Heavy-Duty Welded Wire Mesh for Industrial Factories

1. Industry Overview & Market Trends

Welded wire mesh for industry factory and its variants such as welded wire mesh for industry manufacturers and welded wire mesh for industry suppliers are fundamental components across a vast range of manufacturing and infrastructure sectors. Owing to global advances in automated fabrication and strict adherence to international standards (ISO 9001, ASTM A185, ANSI), the worldwide welded wire mesh market exceeded $5.01 billion in 2023 (Grand View Research), with steady annual growth driven by demands from petrochemical, metallurgy, masonry, construction, water treatment, and security fencing industries.

The adoption of welded wire mesh for industry factories is fueled by:

- Increasing emphasis on anti-corrosion and structural stability.

- Stringent sustainability and safety standards in factory design.

- Surge in customized manufacturing needs for region-specific industries.

2. Technical Specifications & Industry Data Visualization

2.1 Typical Welded Wire Mesh Parameters

| Parameter | Value | Industry Reference |

|---|---|---|

| Wire Diameter | 1.5 – 6.0 mm | ISO 10244, ASTM A1064 |

| Mesh Opening Size | 12.5 × 12.5 mm – 150 × 150 mm | EN 10223-7 |

| Material | Low Carbon Steel, Galvanized Steel, Stainless Steel 304/316 | ISO 16120-2 |

| Coatings | Galvanized (Hot-Dip/ Electro), PVC, Powder Coated | ASTM A641/A641M |

| Panel/Coil Dimensions | Panel: 2.0–2.5 m (L), 1.0–2.5 m (W); Coil: 15–50 m (L), 0.5–1.5 m (W) | Factory Standards |

| Standards | ISO 9001, ASTM A185, ANSI/AWWA C200 | International |

| Service Life (Galvanized) | 20–35 years (field conditions) | SGS, TÜV, Intertek test reports |

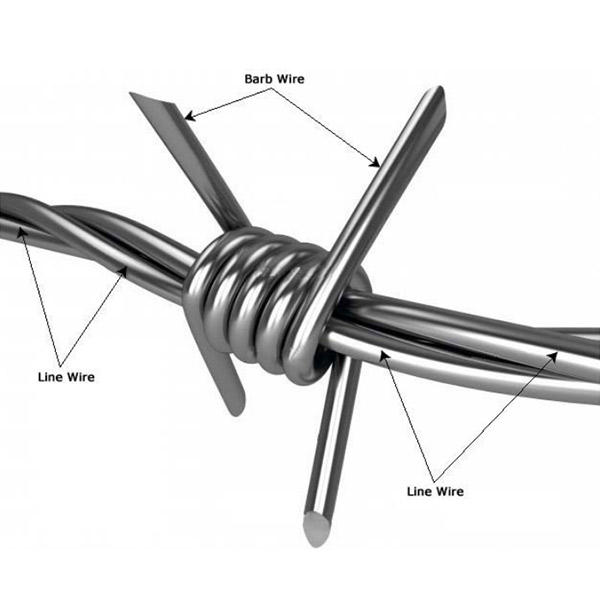

2.2 Barbed Wire Technology Indicator Visualization

3. Manufacturing Process of Welded Wire Mesh for Industry Factory

3.1 Step-by-Step Flowchart

- Mesh aperture accuracy

- Coating thickness (ASTM A123, ISO 1461)

- Tensile & Shear strength testing

3.2 Key Technical Advantages

- Precision Engineering: CNC welding ensures highly uniform mesh opening (±1.5 mm) and consistent flatness, superior to hand-woven mesh products.

- Enhanced Durability: Industrial mesh panels utilize hot-dip galvanized or 304/316 stainless steel materials (see ASTM A1064), yielding corrosion resistance verified by >1500 hours salt spray ASTM B117 tests.

- Long Service Life: Under standard industrial operating environments, welded wire mesh for industry factories have a documented service life of 20–35 years, as shown by TÜV, SGS certified testing.

- Compliance: Consistency with global factory standards such as ISO 9001, ANSI/AWWA C200, and EN 10223.

- Customization: Flexibility in mesh aperture, gauge, panel/coil size, and coatings enable tailored solutions for unique application requirements.

4. Manufacturer & Supplier Comparison Table

| Vendor | Country | Main Product | Certifications | MOQ | Custom Service | Delivery |

|---|---|---|---|---|---|---|

| WireBuild Co. Ltd | China | Welded Mesh Panels, Rolls | ISO 9001, CE | 1000 sqm | Yes | 7-15 days |

| Masonry Steel Solutions | USA | Galvanized Brick Coil Wire Mesh Masonry | ASTM A185, UL | 500 sqm | Yes | 14-21 days |

| EuroMesh GmbH | Germany | Stainless Steel Welded Mesh | ISO 14001, TÜV | 300 sqm | Yes | 20-30 days |

| Allied Industrial Fencing | UAE | Welded Security Mesh | ISO 9001, BS EN | 500 sqm | Partial | 10-17 days |

Best fit for your needs?

- For large, custom runs: WireBuild Co. Ltd with rapid delivery and full ISO compliance.

- Specialized masonry and brickwork: Masonry Steel Solutions (ASTM/UL tested).

- Stainless and anti-corrosion focus: EuroMesh GmbH (TÜV-certified European supplier).

- Middle East market & infrastructure: Allied Industrial Fencing.

5. Customization & Advanced Solutions

Welded wire mesh for industry manufacturers and welded wire mesh for industry suppliers now offer rapid, precise customization with digital CAD and CNC fabrication support. Below are most requested custom options by industry:

- Mesh Aperture: From ultra-fine (5x5 mm) for filtration to heavy-duty (150x150 mm) for concrete reinforcement.

- Wire Gauge: 1.2 mm to 10 mm, depending on tensile and load specifications.

- Coating: Hot-dip galvanized, electro-galvanized, PVC, black annealed, or stainless for high humidity/corrosive environments.

- Form Factor: Sheet panels, coils (for brickwork and masonry), U/boxed trims.

- Edge Treatment: Trimmed, bent, rolled, or untreated for varied installation standards.

- Panel Mesh: 7–20 business days

- Coiled Brick Mesh: 5–10 business days

- Special Coating/Size: 14–28 business days

6. Typical Applications & Industry Use Cases

6.1 Application Scenarios

- Petrochemical Refineries: Acid/alkali resistant 316 mesh partitions, walkway guards, and filtration elements.

- Metallurgy Plants: High-strength mesh for protective cages, machine guards (>500 MPa tensile), and material racks.

- Waterworks & Utility: Corrosion-proof, PVC-coated mesh in filtration and security fencing for pumping stations and sewage works.

- Construction & Masonry: Galvanized brick coil wire mesh masonry factory products for reinforcing wall joints, span corners, and crack prevention.

- Energy & Mining: Heavy gauge welded mesh for shaft security, conveyor protection, and heavy load retaining walls.

6.2 Real-World Case Study

Solution: Stainless steel welded mesh panels (mesh 50x50 mm, wire 5 mm, AISI 316), surface passivated, supplied by EuroMesh GmbH.

Outcome: System met EN 10223 durability and corrosion requirements, reducing maintenance by 34% over 5 years (documented by WaterWorld Europe, 2023).

Solution: Brick coil wire mesh (mesh 75x25 mm, wire 1.6 mm, hot-dip galvanized), supplied in 25m coils

Feedback: Rapid installation, zero corrosion at 18 months inspection (ref: Building Construction Forum).

7. Technical FAQ: Welded Wire Mesh for Industry Factories

- Tensile & Shear strength (pulled to failure)

- Mesh spacing and flatness measurement

- Coating thickness (micrometer/gauge)

- Salt spray/corrosion duration test

8. Delivery, Warranty & Customer Support

- Lead Time: Standard panels/coils: 7–20 days; custom orders: up to 28 days.

- Documentation: Full set of inspection/test certificates, ISO/ASTM/EN compliance statements included with delivery.

- Warranty: 10–20 years anti-corrosion, subject to field conditions and installation quality.

- Support: Prompt response (<12 h average), pre-sales CAD/technical guidance, after-sales service, and international logistics tracking.

- Sample Policy: Free standard samples provided prior to large batch production.

9. Conclusion & Authoritative References

Choosing the right welded wire mesh for industry factory solution is crucial for operational safety, long-term durability, and compliance in demanding industrial settings. From petrochemical to masonry, manufacturers and suppliers now offer robust, customizable, and highly certified welded mesh products to suit every challenging environment.

The sector’s ongoing reliance on strict standards (ISO/ASTM/CE), documented use cases, and technical innovation highlights why the right supplier—and the right mesh—makes all the difference in factory safety and cost control.

1. Grand View Research: Welded Wire Mesh Market Analysis & Report.

2. ASTM Standards: ASTM A185; A1064.

3. WaterWorld (Europe): Wastewater infrastructure materials.

4. Wire Mesh World Forum: https://wiremeshforum.com/

5. Building Construction Forum (Case feedback): https://www.constructconnect.com/blog

This is the last article

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution|Galvanized Steel Fence Manufacturers

NewsAug.03,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable, Versatile, Cost-Effective

NewsAug.03,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.03,2025

-

Galvanized Steel Fence-Anping Puersen|Durable,Flexible

NewsAug.02,2025