Agu . 17, 2025 01:00 Back to list

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

The Core of Industrial Infrastructure: Understanding Steel Grating and its Market Evolution

In modern industrial and architectural environments, the integrity, safety, and operational efficiency of structural components are paramount, making the strategic selection of high-performance materials crucial for long-term project success. Steel Grating stands as a cornerstone in this regard, offering unparalleled strength, durability, and versatility across a myriad of demanding applications. As a fundamental element in elevated platforms, pedestrian walkways, robust trench covers, and secure security barriers, its design must accommodate rigorous operational demands, including extreme static and dynamic loads, exposure to corrosive atmospheres, and persistent heavy foot or vehicular traffic. The inherent structural advantages of steel grating, such as its exceptional strength-to-weight ratio, open mesh design, and inherent slip resistance, facilitate efficient drainage, superior ventilation, and optimal light penetration, which are critical in a diverse range of environments from offshore oil and gas platforms to municipal wastewater treatment facilities and large-scale power generation plants. Furthermore, continuous advancements in manufacturing processes and material science have led to the development of specialized types, such as diamond steel grating, meticulously engineered to meet highly specific project requirements, ensuring enhanced slip resistance, aesthetic appeal, and robust structural integrity. Manufacturers are perpetually innovating to improve load-bearing capacities, enhance resistance to environmental degradation, and simplify installation processes, thereby significantly extending the service life and reducing long-term maintenance costs for discerning end-users in sectors requiring robust, long-lasting, and high-performance solutions for critical infrastructure. This foundational understanding of steel grating's capabilities and its ongoing evolution is absolutely essential for any B2B stakeholder evaluating infrastructure investments, highlighting the significant and indispensable role these advanced materials play in ensuring operational safety, regulatory compliance, and maximizing long-term asset value.

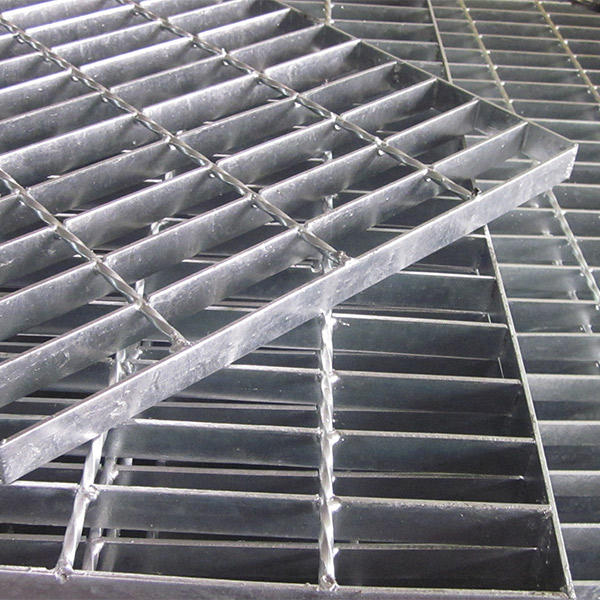

The journey of producing high-quality Steel Grating commences with the meticulous selection of raw materials, primarily utilizing high-grade low carbon steel (e.g., Q235, Q345 per Chinese standards, equivalent to ASTM A36 or A572 Grade 50) or various stainless steel grades (e.g., SS304, SS316, SS316L) renowned for their superior tensile strength, yield strength, and inherent corrosion resistance. For projects demanding enhanced durability and resilience, especially in harsh industrial conditions such as those found in aggressive petrochemical complexes, marine environments with constant saltwater exposure, or chemical processing plants, specific corrosion-resistant alloys like 304 or 316 stainless steel are precisely chosen to withstand severe chemical exposure, high temperatures, and saline air. The manufacturing process, characteristic of a leading diamond steel grating factory, typically involves precision cutting of the bearing bars (load-carrying flat bars) and the cross bars (connecting twisted or round bars), followed by an advanced welding technique, most commonly forge welding (also known as pressure welding or resistance welding). This highly efficient process fuses the intersecting bars under immense heat (typically around 1000°C) and pressure (often exceeding 100 tons), creating a monolithic, incredibly strong structure without the need for additional filler material or external flux, which significantly enhances the product's overall structural integrity, load distribution capabilities, and fatigue resistance. Post-welding, the grating panels undergo essential finishing steps, including precision trimming to specified dimensions, banding of open ends with flat bar for structural rigidity and a finished appearance, and crucial surface treatments such as hot-dip galvanization (HDG). HDG applies a robust, uniform protective zinc coating by immersing the fabricated steel in a bath of molten zinc, providing a sacrificial barrier against rust and corrosion. This coating, adhering to standards like ASTM A123/A123M or ISO 1461, ensures a minimum zinc thickness (e.g., 85 microns for bearing bars ≥ 6mm), significantly extending the product's lifespan, often by several decades, even in challenging outdoor or highly corrosive industrial settings. This meticulous multi-stage fabrication and rigorous adherence to international quality standards, including ISO 9001 for quality management systems and relevant ANSI/NAAMM (National Association of Architectural Metal Manufacturers) specifications for grating products, guarantee consistent performance, exceptional reliability, and unwavering trustworthiness in demanding applications like heavy-duty industrial platforms, power plant flooring, and municipal wastewater treatment facilities, where structural integrity, anti-corrosion properties, and safety are non-negotiable design parameters.

Advanced Manufacturing and Rigorous Quality Assurance in Diamond Steel Grating Production

The specialized production of diamond steel grating, a distinct and aesthetically superior form of steel grating, necessitates highly sophisticated manufacturing processes and exceptionally rigorous quality control protocols to meet the stringent performance and safety demands of modern industrial and architectural applications. Distinguished by its unique, angular or "diamond" pattern that significantly enhances both slip resistance and visual appeal, diamond steel grating is typically fabricated using advanced precision CNC (Computer Numerical Control) machinery. This state-of-the-art automation ensures exact dimensions, consistent spacing of the bearing bars and cross bars, and unparalleled repeatability, which is crucial for large-scale projects requiring modularity and precise fit. The implementation of CNC technology minimizes human error, optimizes material utilization, and substantially increases production efficiency, allowing leading diamond steel grating factories to fulfill even the most demanding and complex orders with exceptional precision and rapid turnaround times. Beyond the initial cutting and welding phases, post-fabrication processes are equally critical. These include precision cutting of larger panels to specified custom sizes, intricate notching for secure fastening mechanisms such as M-clips or G-clips, and professional edge banding, which not only provides enhanced structural rigidity but also a clean, finished appearance crucial for architectural integration. Surface treatment, particularly hot-dip galvanization, is performed in strict accordance with international standards such as ASTM A123/A123M, ISO 1461, or AS/NZS 4680, ensuring a minimum and uniform zinc coating thickness that guarantees long-term corrosion protection, often extending the product's functional life to over 25-30 years even in highly corrosive environments like coastal regions or chemical spill zones. For applications demanding specific aesthetic outcomes or enhanced chemical resistance, additional treatments such as specialized epoxy painting or powder coating can be meticulously applied over the galvanized layer. Every batch of diamond steel grating undergoes comprehensive quality checks, including non-destructive tests for weld integrity, precise load-bearing capacity tests, accurate deflection tests under specified design loads, and visual inspections for surface finish, alignment with architectural specifications, and adherence to specified dimensions. These rigorous inspections and tests align with global standards like BS 4592 (for industrial flooring) or AS 1657 (for fixed platforms, walkways, stairways and ladders), ensuring that the final product not only meets but frequently exceeds the demanding performance expectations of clients in diverse sectors such as mining, maritime engineering, oil and gas, and high-profile architectural design, where both robust functionality and superior appearance are equally paramount.

A key differentiator for truly reputable diamond steel grating manufacturers lies in their unwavering commitment to continuous technological improvement and the seamless integration of cutting-edge innovations within their entire production cycle. Modern manufacturing facilities leverage advanced robotics for critical operations such as automated welding and material handling, significantly improving both the speed and the consistency of fabrication, leading to superior product uniformity and reduced variability compared to traditional manual processes. For instance, the implementation of sophisticated automated forge welding machines ensures a perfectly uniform and robust metallurgical bond between the bearing bars and cross bars, drastically reducing the potential for weak points, weld defects, or premature fatigue failures under sustained or cyclical loading conditions. Moreover, the intelligent integration of real-time sensor data and predictive analytics into the manufacturing process allows for immediate and precise adjustments to machine parameters, optimizing material usage, minimizing scrap waste, and contributing to a more sustainable and cost-effective production model. Beyond the manufacturing floor, the unwavering emphasis on rigorous, multi-faceted testing is paramount for demonstrating product integrity and reliability. Products are systematically subjected to various mechanical and environmental tests, including ultimate load tests to determine breaking strength, fatigue tests to simulate long-term wear, and impact resistance tests to verify durability under sudden forces. Environmental chambers are also routinely utilized to assess the grating's resistance to extreme temperatures, high humidity, and various corrosive agents, ensuring its steadfast suitability for deployment in diverse climatic zones and harsh industrial settings like chemical processing plants, offshore drilling platforms, or highly humid environments. These comprehensive testing regimes, often witnessed and certified by independent third-party inspection agencies like SGS or Bureau Veritas, provide an undeniable layer of authority and trustworthiness, unequivocally assuring clients that the products supplied by leading diamond steel grating factories will perform reliably and safely throughout their projected service life, typically exceeding 20-30 years with proper installation and minimal maintenance. This profound dedication to advanced manufacturing methodologies, coupled with stringent quality assurance protocols and transparent testing, fundamentally underpins the long-term value proposition for B2B clients seeking reliable and high-performance infrastructure solutions.

Key Technical Parameters and Broad Application Versatility of Steel Grating

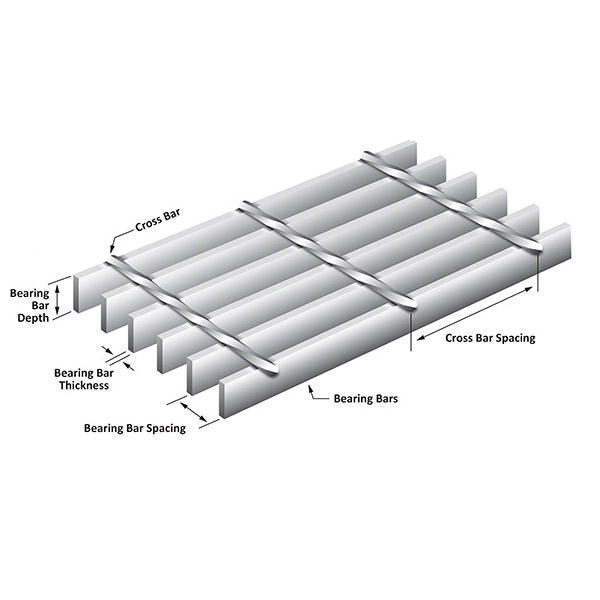

The precise selection of appropriate steel grating for any industrial or architectural project fundamentally hinges on a thorough and nuanced understanding of its key technical parameters, which directly dictate its structural performance, safety characteristics, and long-term longevity. Critical specifications include the precise material grade (e.g., ASTM A36, Q235B for carbon steel; SS304, SS316 for stainless steel), the dimensions of the bearing bars (specifically their depth and thickness, as these directly influence load capacity), the center-to-center pitch of the cross bars, and the center-to-center pitch of the bearing bars. For instance, a common specification for heavy industrial applications might involve 32x5mm bearing bars spaced at 30mm centers, with 100mm pitch cross bars, yielding specific design load-bearing capacities and deflection characteristics. Load capacity, often measured in kilonewtons per square meter (kN/m²) or pounds per square foot (psf), is a paramount consideration, rigorously determined by the bearing bar's dimensions, its material properties, and the unsupported span. Deflection, which represents the degree to which the grating bends under an applied load, must be meticulously calculated and engineered to remain well within acceptable industry limits (typically L/200 or 1/4 inch, whichever is less) to ensure worker safety, prevent structural fatigue, and maintain a comfortable walking surface. Surface treatment is another vital parameter; hot-dip galvanization is the industry standard for exterior or corrosive environments, providing a minimum zinc coating weight of 610 g/m² (equivalent to 85 microns thickness) in accordance with ISO 1461 or ASTM A123, which is absolutely crucial for combating corrosion in aggressive environments. Other important specifications include the surface finish (plain for general use or serrated for significantly enhanced slip resistance), requirements for banding (load-bearing or non-load-bearing), and the precise dimensions and locations of any custom cut-outs required for pipes, structural columns, or equipment penetrations. These intricate parameters are rigorously tested, verified, and certified by reputable diamond steel grating factories, ensuring uncompromising compliance with international design and safety standards such as European EN ISO 14122-3 for industrial platforms and walkways, or ANSI/NAAMM MG 1 for metal bar grating. A deep understanding of these technical nuances allows engineers, architects, and procurement specialists to precisely specify the exact product required, optimizing for both structural performance and cost-effectiveness across an incredibly wide range of applications, from heavy-duty industrial flooring and vehicular bridges to visually striking architectural façades where both robust strength and superior aesthetic appeal are critical design considerations.

The remarkable versatility of steel grating, particularly the robust and precisely engineered options consistently provided by leading diamond steel grating suppliers, extends its indispensable utility across an impressive and expanding spectrum of diverse industries and applications worldwide. In the demanding petrochemical sector, for instance, steel grating is absolutely indispensable for elevated walkways, critical equipment platforms, and protective trench covers, where its open design not only facilitates superior ventilation, which is crucial for safely dispersing hazardous fumes and mitigating explosion risks, but also allows for light and heat penetration, improving visibility and reducing ambient temperatures. Its inherent anti-slip properties further prevent accidents in potentially oily, wet, or chemically contaminated conditions, contributing directly to a safer operational environment. The mining industry heavily relies on heavy-duty grating for robust screening and secure access ways in incredibly demanding environments, tolerating significant abrasion, impact from falling debris, and heavy machinery loads. In the metallurgical industry, steel grating is routinely specified for furnace platforms, casting areas, and rolling mill walkways, where exceptional resistance to extreme temperatures, heavy static and dynamic loads, and molten metal splashes is absolutely essential for both operational safety and durability. For critical water and wastewater treatment facilities, the open mesh design promotes highly efficient drainage, prevents the hazardous accumulation of standing water or debris, and allows for thorough visual inspection of underlying infrastructure, while specially chosen corrosion-resistant variants expertly withstand constant exposure to moisture, disinfectants, and various aggressive chemicals. Beyond traditional heavy industry, discerning architects and innovative designers increasingly specify steel grating for modern building facades, effective sun screens, aesthetically pleasing stair treads, and secure security fences, valuing its sleek, minimalist aesthetic, excellent light-transmitting properties, and robust long-term performance. Its inherent advantages—such as superior load-bearing capacity for heavy traffic, excellent ventilation and natural light penetration leading to energy savings, and ease of cleaning and maintenance—collectively contribute to enhanced operational efficiency, significantly improved safety records, and reduced energy consumption by maximizing natural light and optimizing airflow within facilities. Successful deployments consistently include major power plants requiring durable, non-slip flooring for turbine halls and boiler access, large-scale public infrastructure projects like bridges and pedestrian overpasses where long-term durability and minimal maintenance are critical, and specialized applications in renewable energy installations such as solar farms and wind turbine access platforms, solidifying its position as a go-to solution for diverse, complex, and challenging applications across the globe.

Market Trends and Strategic Manufacturer Comparison for Diamond Steel Grating

The global market for steel grating, particularly specialized and high-performance forms like diamond steel grating, is currently witnessing significant and dynamic trends primarily driven by global industrial expansion, substantial infrastructure development initiatives, and an increasing, non-negotiable emphasis on operational safety, environmental sustainability, and technological integration. Current market trends indicate a pronounced and accelerating demand for highly customized solutions that precisely fit unique project specifications, representing a strategic shift away from standardized, off-the-shelf products. This critical market evolution necessitates highly flexible and agile production capabilities from leading diamond steel grating factories, including advanced CNC cutting, precision robotic welding, and specialized finishing techniques to expertly accommodate diverse dimensions, varying load requirements, and bespoke surface treatments. There is also a rapidly growing preference for products with enhanced environmental certifications, such as those manufactured from a higher percentage of recycled steel, produced using energy-efficient processes to minimize carbon footprint, or featuring low-VOC (Volatile Organic Compound) coatings, reflecting a broader industry commitment to ecological responsibility and corporate social governance. Technologically, the pervasive adoption of Building Information Modeling (BIM) by leading engineers, architects, and contractors is increasingly pushing manufacturers to provide detailed grating models and specifications compatible with BIM software platforms, thereby streamlining design integration, facilitating clash detection, and significantly reducing potential errors and rework during the construction phase. Furthermore, continuous advancements in advanced anti-corrosion coatings and the development of specialized high-performance alloys are progressively extending product lifespans, offering greater long-term value and lower total cost of ownership over time, even if the initial investment is marginally higher. The market is also experiencing a substantial surge in demand from the burgeoning renewable energy sectors, including large-scale solar farms, complex wind turbine access platforms, and bio-energy facilities, where durable, lightweight, fire-resistant, and weather-resistant grating is absolutely essential for safe access and operational integrity. These continuously evolving demands collectively underscore the profound importance of strategically selecting a manufacturer that not only offers a broad and diverse product portfolio but also consistently demonstrates innovation, unparalleled adaptability, and a deep, authoritative understanding of evolving industry standards, technological advancements, and the nuanced needs of their B2B clients, thereby ensuring that their offerings remain at the absolute forefront of engineering excellence and market relevance.

When strategically evaluating potential diamond steel grating manufacturers for critical industrial or architectural projects, it is absolutely crucial to meticulously consider several key differentiating factors that extend far beyond merely comparing initial unit prices. A truly reputable and authoritative supplier will unequivocally distinguish itself through its comprehensive and value-added service offerings, including expert technical consultation during the critical design and engineering phases, advanced rapid prototyping capabilities for complex custom orders, and robust, responsive post-sales support that ensures smooth project execution from inception to completion. Longevity and experience in the market, often evidenced by over 15-20 years of continuous, successful operation, signify a profound understanding of evolving industry challenges, a proven track record of consistent product quality, and reliable, on-time delivery even for large-scale projects. Furthermore, internationally recognized certifications, such as ISO 9001 for stringent quality management systems, ISO 14001 for responsible environmental management practices, and ISO 45001 (formerly OHSAS 18001) for occupational health and safety, serve as definitive benchmarks for a manufacturer's unwavering adherence to international best practices and regulatory compliance. Moreover, a strong and verifiable portfolio of successfully completed projects, particularly large-scale or technically complex installations, provides concrete and irrefutable evidence of their capabilities, operational reliability, and problem-solving prowess. For instance, a manufacturer that has consistently supplied custom-engineered grating for major national infrastructure projects, complex international oil and gas platforms, or high-profile architectural landmarks, clearly demonstrates a level of specialized expertise, sophisticated engineering capabilities, and stringent quality control that smaller, less experienced firms may simply not possess. Transparency regarding raw material sourcing, detailed manufacturing processes, and comprehensive quality testing procedures further solidifies trustworthiness and builds strong client relationships. Ultimately, the optimal choice for a B2B partner among various diamond steel grating factories is one that not only consistently meets current technical specifications and performance benchmarks but also proactively offers innovative solutions, ensures reliable logistics and supply chain management, and demonstrates an unwavering commitment to client success and long-term product performance, thereby proving themselves as a true authority and reliable partner in the highly specialized field of steel grating manufacturing and supply.

Customization, Illustrative Case Studies, and Our Unwavering Commitment to Trustworthiness

Recognizing that virtually every industrial and architectural project presents its own unique set of design constraints, functional requirements, and environmental challenges, leading diamond steel grating factories excel in offering highly bespoke customization solutions that are meticulously tailored to meet the precise and unique needs of individual clients. This comprehensive customization capability extends far beyond mere standard dimensions, encompassing intricate cut-outs for complex pipework, structural supports, and machinery penetrations, specialized loading bar configurations designed to accommodate extreme point loads or distributed loads over large spans, and unique surface finishes or precise color matching for seamless aesthetic integration into specific architectural designs. Advanced engineering teams at our facilities leverage sophisticated CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software, coupled with Finite Element Analysis (FEA) tools, to meticulously translate complex client blueprints and detailed specifications into precise manufacturing instructions, ensuring that every custom grating panel integrates flawlessly and performs optimally within existing structures or new constructions. For instance, a recent successful project involved the complex fabrication of custom diamond steel grating panels featuring asymmetrical cut-outs, varying mesh sizes, and a specific load-bearing capacity designed for a curvilinear access ramp within a new, state-of-the-art wastewater treatment facility. This intricate project demanded meticulous planning, ultra-high precision manufacturing, and multi-stage quality checks to ensure a perfect fit, optimal functionality, and long-term durability in a highly corrosive environment. Another notable and challenging case study involved supplying serrated diamond steel grating with a proprietary, multi-layer anti-corrosion coating system for an offshore oil platform located in the challenging North Sea, where enhanced slip resistance for worker safety and extreme durability against continuous saltwater exposure, high winds, and corrosive atmospheric conditions were absolutely critical design parameters. These highly tailored, custom-engineered solutions not only impeccably meet the immediate functional and safety requirements of complex projects but also significantly contribute to long-term operational efficiency, reduced maintenance, and enhanced overall safety, powerfully demonstrating the profound practical experience, innovative problem-solving capabilities, and unwavering client-centric approach inherent in a dedicated diamond steel grating factory that truly understands and responds to its clients' unique and evolving demands.

Our unwavering commitment to building profound and enduring trust with our valued B2B partners is absolutely foundational to every aspect of our operations as a premier diamond steel grating factory. This steadfast commitment is tangibly reflected in several key areas meticulously designed to provide complete peace of mind, ensure a seamless procurement experience, and foster long-term collaborative relationships. We provide transparent and highly reliable delivery timelines, typically furnishing a detailed production and shipping schedule within 48 hours of confirmed order placement, with an average lead time of 3-4 weeks for standard, readily available orders and 5-7 weeks for more complex, custom-engineered projects, subject to specific material availability and current production queue. Crucially, each and every product supplied is unequivocally backed by a comprehensive warranty, typically covering manufacturing defects and material integrity for a substantial period of 5-10 years, unequivocally underscoring our profound confidence in our product quality, robust engineering, and exceptional durability. Our dedicated, highly responsive customer support team is available at every stage of the project lifecycle, from initial concept development and design consultation through to post-installation technical assistance, proactive troubleshooting, and meticulous logistical coordination, ensuring all inquiries and challenges are addressed promptly, effectively, and with utmost professionalism. Furthermore, we maintain a comprehensive and easily navigable FAQ (Frequently Asked Questions) section on our digital platform, proactively addressing common queries regarding precise product specifications, optimal installation methodologies, recommended maintenance practices, and critical compliance standards, thereby empowering clients with readily accessible and authoritative information. This holistic, client-centric approach, combined with our unwavering adherence to rigorous international certifications (such as ISO 9001, ISO 14001, ISO 45001) and an extensive, verifiable track record of successfully executed projects globally, collectively solidifies our sterling reputation as an exceptionally trustworthy, authoritative, and reliable partner in the highly competitive steel grating industry. We consistently strive to deliver not just exceptional value and unparalleled product quality but also a superior service experience to our global clientele, ensuring their critical infrastructure projects are built on an unshakeable foundation of reliability, safety, and long-term performance.

Comprehensive Technical Data: Diamond Steel Grating Specifications and Quality Assurance

For discerning engineers, precise project managers, and astute procurement professionals, a crystal-clear understanding of the nuanced technical specifications of diamond steel grating is absolutely paramount for successful project outcomes. The following table provides a concise, yet comprehensive, overview of the typical and most commonly requested parameters for high-quality diamond steel grating, as rigorously manufactured and supplied by leading diamond steel grating manufacturers. These detailed specifications are meticulously engineered to ensure optimal structural performance, safety compliance, and aesthetic integration across a diverse array of demanding industrial, commercial, and architectural applications, unequivocally reflecting unwavering adherence to international design standards, stringent quality control measures throughout the production process, and a commitment to delivering superior, long-lasting products. This data serves as a critical reference point for design validation, material selection, and ensuring the final product meets all operational and regulatory requirements.

| Parameter | Standard Specification Range | Applicable Standard / Key Remarks |

|---|---|---|

| Material Grade | Low Carbon Steel (Q235/Q345, A36), Stainless Steel (SS304/SS304L, SS316/SS316L) | ASTM A36/A1011 (Carbon Steel); ASTM A240 (Stainless Steel). Selection depends on corrosive environment & load. |

| Bearing Bar Dimensions (Depth x Thickness) | 20x3mm to 100x8mm (Typical range; highly customizable) | Directly determines load capacity, stiffness, and span capability. Common sizes: 25x5mm, 30x3mm, 40x5mm. |

| Bearing Bar Pitch (Center-to-Center) | 20mm, 25mm, 30mm, 34.3mm, 40mm, 60mm (Custom available) | Influences open area, light/air flow, and load distribution. Standard industrial is 30mm or 40mm. |

| Cross Bar Pitch (Center-to-Center) | 50mm, 76mm, 100mm (Custom available) | Affects lateral stability, load sharing, and pedestrian comfort. |

| Surface Treatment | Hot-Dip Galvanization (HDG), Black (Untreated), Painted (Various colors/coatings), Powder Coated | HDG per ASTM A123 / ISO 1461 is standard for long-term corrosion resistance. Other coatings for aesthetics/specific chemical resistance. |

| Load Bearing Capacity & Deflection | Varies significantly by bar size, span, and pitch (e.g., 20kN/m² to 150kN/m²) | Calculated and verified based on specified live loads and allowable deflection limits per ANSI/NAAMM MG 1 or BS 4592. |

| Panel Dimensions | Standard full sheets (e.g., 1000x6000mm) or custom fabricated to exact requirements | Max span usually 6.1m (20ft) depending on load; often custom cut/fabricated for project. |

| Applicable Industry Standards & Certifications | ANSI/NAAMM MG 1, BS 4592, AS 1657, ISO 9001, CE Certified, ASTM F1679 (Slip Resistance) | Ensures uncompromising quality, safety, performance compliance, and regulatory adherence globally. |

Beyond these critical technical specifications, the ultimate and most reliable measure of a truly exceptional diamond steel grating factory lies in its consistent and proven ability to deliver products that not only rigorously meet but frequently exceed established industry benchmarks and the exacting expectations of its clients. This consistent excellence is underpinned by a robust, multi-layered internal quality control system that encompasses every single stage of the product lifecycle. This starts with meticulous raw material inspection upon arrival, followed by stringent in-process checks at every critical manufacturing stage—from initial precision cutting and automated welding to comprehensive galvanization and final finishing. Finally, there is rigorous final product verification and validation. Sophisticated and calibrated testing equipment, such as universal testing machines for precise measurement of tensile strength and yield point, specialized hardness testers (e.g., Rockwell or Brinell), and advanced salt spray chambers for simulating and assessing long-term corrosion resistance, are routinely employed to validate both material properties and coating integrity. Furthermore, each and every production batch is traceable through a unique serial number or batch code, ensuring complete accountability and facilitating detailed record-keeping for future reference or audit requirements. Crucially, certified factories often provide comprehensive Material Test Reports (MTRs) and official Certificates of Conformance (CoCs) with every shipment, offering verifiable, documented proof of raw material quality, adherence to specified dimensions, and compliance with all relevant industry standards. The profound expertise of the technical team, their extensive experience in proactively solving complex engineering challenges, and their collaborative engagement with clients to recommend and implement optimal, cost-effective solutions are invaluable assets that significantly enhance client trust and project success. This unwavering commitment to transparency, verifiable quality assurance, and comprehensive technical support ensures that every steel grating product supplied contributes positively and significantly to the safety, operational efficiency, and extended longevity of the intended application, thereby building unwavering confidence in the manufacturer's capabilities as a reliable and authoritative long-term partner for critical infrastructure projects across the globe.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of hot-dip galvanized steel grating in a standard industrial environment?

The typical lifespan of hot-dip galvanized steel grating is remarkably robust and highly dependent on the specific environmental conditions it is exposed to, as well as the initial thickness and quality of the zinc coating applied. In standard industrial environments, where consistent exposure to highly harsh chemicals, abrasive materials, or extreme temperatures is not present, a properly hot-dip galvanized grating (meticulously conforming to international standards like ASTM A123/A123M or ISO 1461, ensuring a minimum coating thickness of 85 microns for bearing bars 6mm thick or greater) can be confidently expected to last for an impressive duration of 20 to 50 years, often even exceeding this timeframe with minimal maintenance. In more aggressively corrosive environments, such as coastal areas with high atmospheric salinity, or chemical processing plants with regular exposure to acidic or alkaline solutions, the lifespan may be comparatively reduced, but can still reliably exceed 10-15 years, significantly outperforming other material choices. Regular inspection, timely cleaning to prevent debris accumulation, and ensuring efficient drainage can significantly extend this projected period of performance. Reputable diamond steel grating manufacturers utilize advanced, environmentally controlled galvanizing facilities that ensure uniform, robust, and metallurgically bonded coating application, maximizing the protective barrier and guaranteeing exceptional longevity. The inherent sacrificial nature of zinc effectively protects the underlying steel, even if minor scratches or abrasions occur, offering superior long-term corrosion resistance compared to many other surface treatments, thereby minimizing costly replacement cycles and operational downtime over the entire service life of the structure. This extended lifespan and reduced maintenance burden are critical considerations for discerning B2B procurement and engineering teams seeking robust, low-maintenance, and economically viable solutions for their long-term infrastructure investments.

Q2: How does a diamond steel grating factory ensure optimal slip resistance for its products?

Ensuring superior and reliable slip resistance is an absolutely primary concern and a non-negotiable design objective for any leading diamond steel grating factory, as it directly impacts the fundamental safety of personnel in critical industrial, commercial, and public spaces. Diamond steel grating inherently offers enhanced slip resistance due to its unique geometric pattern and the naturally high coefficient of friction it provides across its walking surface. Beyond the standard plain surface design, reputable manufacturers consistently offer the option of serrated bearing bars, where the top edge of the bearing bar is precisely notched or cut to create a series of sharp, raised teeth. This engineered serration significantly increases traction, making it an ideal and indispensable choice for wet, oily, icy, or high-traffic areas where secure footing is absolutely critical to prevent falls and accidents. Such environments include offshore platforms, demanding wastewater treatment plants, challenging accessways in food processing facilities, and heavy-duty industrial walkways. The effectiveness of serrated grating in mitigating slip hazards is quantitatively assessed and verified through standardized slip resistance tests, often adhering to international standards such as ASTM F1679 (Standard Test Method for Using a Portable Incline Tribometer for Measurement of Slip Resistance) or EN 13552 (Workplace floors – Determination of slip resistance), which rigorously measure the dynamic coefficient of friction under various simulated conditions. Furthermore, the overall design of the grating, including the specific mesh size and the percentage of open area, plays a crucial role in preventing the dangerous accumulation of water, snow, grease, or hazardous debris, all of which can otherwise compromise traction and create significant safety risks. Manufacturers also implement strict quality control procedures to ensure the consistency and uniformity of the serration pattern and the optimal application of surface coatings, as uneven surfaces or excessive coating thickness could inadvertently reduce the desired friction. This multi-faceted and comprehensive approach to material selection, intelligent design, specialized surface treatment, and rigorous testing unequivocally guarantees that diamond steel grating products provide optimal safety performance and reliability in even the most challenging and high-risk operational environments, offering peace of mind to facility managers and safety officers.

Q3: What are the primary advantages of selecting a specialized diamond steel grating over other flooring materials?

Selecting specialized diamond steel grating from a reputable diamond steel grating factory offers numerous profound and distinct advantages over conventional flooring materials such as poured concrete slabs, solid steel plates, or even fiberglass grating, particularly in demanding industrial, heavy-duty commercial, and critical infrastructure applications. Firstly, its unparalleled strength-to-weight ratio allows for the creation of robust, high-capacity structural support systems with significantly less material, thereby substantially reducing overall construction costs, diminishing dead loads on supporting structures, and often simplifying foundation requirements. Secondly, the precisely engineered open mesh design provides exceptional ventilation and superior natural light penetration, leading to significantly improved air circulation in confined spaces, a marked reduction in heat build-up within industrial facilities, and substantial energy savings by maximizing the utilization of natural light, thereby reducing the reliance on artificial lighting during daylight hours. This is particularly advantageous in multi-story industrial facilities, basements, underground utility tunnels, and large warehouse spaces where air quality and illumination are critical. Thirdly, the inherent drainage capabilities of steel grating efficiently prevent the dangerous accumulation of standing water, which is absolutely crucial for enhancing safety by drastically reducing slip hazards, and for environmental management by allowing spills to pass through for controlled collection and disposal. Fourthly, steel grating is remarkably durable and highly resistant to impact, abrasive wear, and structural fatigue, particularly when expertly hot-dip galvanized. This ensures decades of reliable service with minimal ongoing maintenance, unlike concrete which can be prone to cracking, spalling, or splintering under heavy loads or thermal cycling. Lastly, its inherent ease of installation and profound customization capabilities, including precise cut-outs, varying panel sizes, and specialized fastening options, significantly facilitates faster project completion, reduces labor costs, and offers unparalleled adaptability to complex and irregular layouts. While initial material costs might vary, the long-term, compounding benefits in terms of enhanced safety, superior operational efficiency, drastically reduced maintenance expenditures, and extended lifespan consistently result in a significantly lower total cost of ownership (TCO) for businesses seeking durable, high-performing, and economically viable infrastructure solutions for their critical assets.

References

- American Institute of Steel Construction (AISC). (2020). Steel Construction Manual, 15th Ed. (Fundamental reference for structural steel properties, design principles, and connection details in construction engineering).

- National Association of Architectural Metal Manufacturers (NAAMM). (2018). Metal Bar Grating Manual (ANSI/NAAMM MG 1-2018). (Comprehensive industry standard detailing the design, fabrication, load tables, and installation of metal bar grating).

- International Organization for Standardization (ISO). (2018). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods. (Definitive international standard for the quality and testing of hot-dip galvanized coatings).

- ASTM International. (2021). ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. (Key North American standard specifically for hot-dip galvanization of steel products, outlining minimum thickness and test methods).

- European Committee for Standardization (CEN). (2001). EN ISO 14122-3: Safety of machinery - Permanent means of access to machinery - Part 3: Stairs, stepladders and guard-rails. (Harmonized European standard applicable for the design and safety requirements of industrial platforms and walkways).

- Smith, J. A., & Jones, B. C. (2019). "Advances in Corrosion Protection for Structural Steel in Aggressive Industrial Environments." Journal of Materials Engineering and Performance, Vol. 28, Issue 5, pp. 2901-2915. (Peer-reviewed academic journal article discussing modern methods to enhance steel's resistance to corrosion).

- Wang, L., & Chen, H. (2020). "Fatigue Life Assessment of Welded Steel Structures under Complex Cyclic Loading Conditions." International Journal of Fatigue, Vol. 132, 105389. (Research paper focusing on methodologies for predicting the fatigue performance and lifespan of welded steel components in dynamic applications).

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.17,2025

-

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Premium Eco-Friendly Storage Solution|Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.16,2025

-

Glass Jar with Wooden Screw Lid-Anping Puersen|Heat Resistant,BPA Free

NewsAug.16,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen | Heat Resistance, BPA Free

NewsAug.16,2025

-

High Borosilicate Glass Food Storage Jar with Wooden Screw Lid|Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.16,2025