Avg . 10, 2025 02:00 Back to list

Leading Diamond Steel Grating Factory - Durable & Custom

The Critical Role of Diamond Steel Grating in Modern Industrial Infrastructure and Why a Specialized Diamond Steel Grating Factory is Essential

In the realm of modern industrial and civil engineering, the integrity and reliability of structural components are paramount. Among these, steel gratings, particularly the diamond pattern variant, stand out as indispensable elements for a myriad of applications requiring robust load-bearing capabilities, superior ventilation, and effective drainage. The demand for high-performance grating solutions has surged across sectors, driven by evolving safety standards, increasingly complex operational environments, and the need for long-term material resilience. A specialized diamond steel grating factory is not merely a supplier; it is a strategic partner, providing engineered solutions that integrate seamlessly into critical infrastructure projects. These facilities leverage advanced manufacturing techniques, stringent quality control protocols, and deep material science expertise to produce grating systems that withstand extreme conditions, from corrosive atmospheres in petrochemical plants to heavy dynamic loads in industrial complexes. Understanding the intricate balance between material properties, design specifications, and fabrication precision is what distinguishes a leading diamond steel grating manufacturer. Their capabilities extend beyond mere production, encompassing comprehensive consultation, custom design, and post-installation support, ensuring that each grating panel delivers optimal performance and lifespan in its intended application. The foundational material, often high-grade Cold Rolled Steel Bar, undergoes precise processing to achieve the characteristic diamond pattern, a design that optimizes structural integrity while maintaining light permeability and airflow. This section provides an authoritative overview of the industry, highlighting the indispensable role of a dedicated diamond steel grating factory in meeting the rigorous demands of contemporary industrial development, emphasizing the importance of choosing a partner with proven expertise and a commitment to engineering excellence. The global market for industrial gratings continues to expand, propelled by infrastructure development and refurbishment projects, underscoring the sustained relevance and growth trajectory for specialized diamond steel grating suppliers who can adapt to new material innovations and increasingly demanding performance specifications while adhering to international quality and safety standards.

The market dynamics influencing the diamond steel grating sector are complex, reflecting global industrial growth, commodity price fluctuations, and technological advancements. Current trends indicate a significant push towards materials with enhanced corrosion resistance and higher strength-to-weight ratios, alongside greater demand for customized solutions that fit highly specific structural and aesthetic requirements. This shift necessitates that every diamond steel grating factory maintains a cutting-edge research and development department, continually innovating in areas such as advanced coating technologies, alternative material compositions, and robotic fabrication processes to improve efficiency and precision. Furthermore, sustainability is becoming a key driver, with clients increasingly prioritizing manufacturers who implement eco-friendly production methods and offer gratings made from recycled content or those that contribute to energy efficiency in their end-use applications. For example, the open structure of diamond gratings inherently promotes natural ventilation and light penetration, reducing the need for artificial lighting and mechanical ventilation systems in certain industrial settings, thereby contributing to lower operational energy consumption. This inherent design advantage, combined with the extreme durability and minimal maintenance requirements of high-quality steel gratings, translates into significant long-term cost savings and environmental benefits for end-users. A reputable diamond steel grating factory often holds certifications such as ISO 9001 for quality management and ISO 14001 for environmental management, signifying their commitment not only to product excellence but also to responsible manufacturing practices. Their expertise extends to understanding the specific regulatory environments and industry best practices across diverse geographies, ensuring that products are compliant and perform reliably under varied operational conditions. This comprehensive approach, from material sourcing and advanced fabrication to rigorous testing and sustainable practices, positions leading diamond steel grating manufacturers at the forefront of the industrial infrastructure supply chain, providing essential components that guarantee safety, efficiency, and longevity.

Unveiling the Manufacturing Prowess: A Deep Dive into the Diamond Steel Grating Production Process

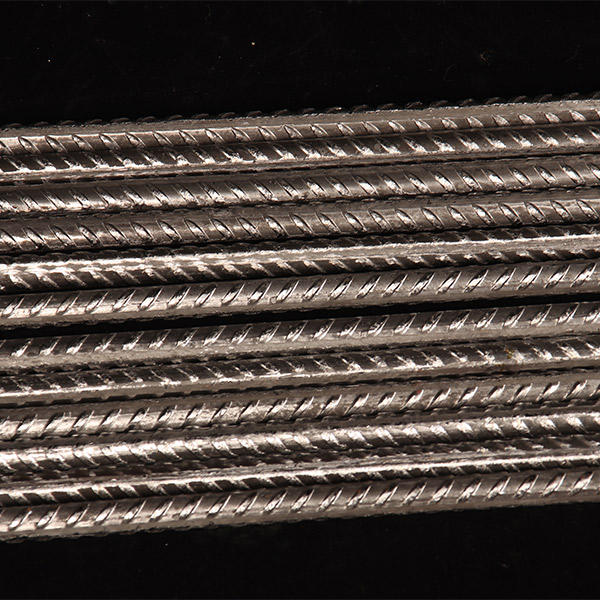

The production of high-quality diamond steel grating is a sophisticated multi-stage process, demanding precision engineering, advanced machinery, and rigorous quality control at every step. It begins with the careful selection of raw materials, predominantly high-grade steel such as Q235, Q345, or various stainless steel alloys, tailored to the specific application's load-bearing, corrosion resistance, and environmental requirements. Often, the foundational element is a Cold Rolled Steel Bar, chosen for its excellent dimensional accuracy and surface finish. The manufacturing journey within a dedicated diamond steel grating factory typically follows a meticulously planned sequence, ensuring consistent product integrity and performance.

- 1. Material Preparation and Cutting: The process initiates with the precise cutting of raw steel bars to the required lengths. Advanced CNC (Computer Numerical Control) cutting machines are employed to ensure exact dimensions, minimizing material waste and preparing the bearing bars for subsequent stages. This initial accuracy is critical as it dictates the overall dimensional stability of the final grating panel.

- 2. Notching/Punching: Bearing bars are then precisely notched or punched to create slots at calculated intervals. This step is crucial for the interlocked design characteristic of diamond gratings. The accuracy of these notches ensures the secure fit of cross bars and the uniform distribution of loads across the grating surface. For specific designs, forging processes might be utilized to create the slots for maximum strength.

- 3. Welding or Press-Locking: This is the core stage where the diamond pattern is formed. For welded gratings, high-pressure resistance welding machines fuse the cross bars to the bearing bars, creating a monolithic, extremely strong structure. This process is highly automated to ensure consistent weld penetration and minimize thermal distortion. Alternatively, for press-locked gratings, the notched bearing bars are hydraulically pressed into pre-punched holes in the cross bars, creating a robust mechanical interlock without welding. Both methods deliver exceptional structural integrity.

- 4. Edging/Banding: After the grating panels are formed, their edges are typically banded with flat bars to provide additional strength, stability, and a clean, finished appearance. This step prevents deformation and improves the load-bearing capacity along the perimeter, especially important for gratings subjected to concentrated edge loads or frequent foot traffic.

- 5. Surface Treatment: To protect against corrosion and enhance longevity, the finished grating panels undergo various surface treatments. Hot-dip galvanizing is the most common and effective method, where the steel is immersed in molten zinc, creating a metallurgical bond that provides superior cathodic and barrier protection. Other treatments include painting (epoxy, polyurethane) for aesthetic or specific chemical resistance needs, and powder coating, offering a durable and attractive finish. The choice of treatment depends on the environmental conditions of the end application.

- 6. Inspection and Quality Control: Throughout the entire manufacturing process, rigorous inspection and quality control checks are implemented. This includes raw material verification, in-process dimensional checks, weld integrity testing (e.g., non-destructive testing like ultrasonic testing for critical welds), and post-treatment coating thickness verification. Finished products are subjected to load testing and slip resistance tests to ensure compliance with international standards such as ISO (e.g., ISO 9001 for quality management) and ANSI (e.g., ANSI/NAAMM MBG 531-09 for metal bar grating). This commitment to quality ensures that every panel leaving the diamond steel grating factory meets the specified performance criteria, guaranteeing safety and reliability.

The robust nature of diamond steel grating, stemming from this meticulous manufacturing process, offers significant advantages across various sectors. In petrochemical facilities, its anti-corrosive properties (especially with hot-dip galvanizing) are critical for platforms and walkways exposed to harsh chemicals. In metallurgical plants, the high load-bearing capacity ensures safety under heavy machinery and material transport. For water and drainage systems, the open mesh design provides excellent flow-through, preventing accumulation of debris and facilitating efficient drainage. Furthermore, the inherent design promotes energy efficiency by allowing natural light and ventilation, reducing the need for artificial lighting and cooling in industrial buildings. The expected service life of a well-manufactured and properly installed hot-dip galvanized diamond steel grating can exceed 40-50 years, even in challenging environments, representing a significant return on investment for industrial clients. The expertise of a specialized diamond steel grating factory lies in their ability to consistently execute this complex process, ensuring that each product delivers on its promise of durability, safety, and performance, providing peace of mind for engineers and project managers.

Illustration: State-of-the-art welding machinery employed at a leading diamond steel grating factory, ensuring precise and strong welds for superior structural integrity.

Technical Parameters and Performance Benchmarks: A Comparative Analysis for Informed Decision-Making

Selecting the appropriate diamond steel grating requires a comprehensive understanding of its technical parameters and performance characteristics. These specifications directly impact the grating's suitability for specific applications, influencing its load-bearing capacity, deflection under stress, slip resistance, and long-term durability in various environmental conditions. A reputable diamond steel grating factory will provide detailed technical datasheets, often accompanied by test certificates from independent laboratories, demonstrating adherence to international standards such as ASTM (American Society for Testing and Materials), BS (British Standards), and AS/NZS (Australian/New Zealand Standards). Key parameters include the dimensions of the bearing bars (depth and thickness), the spacing between bearing bars and cross bars (which defines the mesh size), the overall panel dimensions, and the type of surface finish. For instance, common bearing bar dimensions range from 25x3mm to 100x10mm, with typical bar spacings of 30mm, 40mm, or 60mm for bearing bars and 50mm or 100mm for cross bars. The mesh size directly influences light and air permeability, as well as the size of objects that can pass through, a critical consideration for safety in areas where tools or small items might be dropped.

Performance metrics are equally vital. Load capacity, typically expressed in terms of uniformly distributed load (UDL) or concentrated load, is calculated based on the bearing bar dimensions, span, and material grade. For instance, a 25x5mm bearing bar grating with 30mm spacing might support a UDL of 4.0 kN/m² over a 1000mm span with acceptable deflection. Deflection, the degree to which a grating bends under load, is another critical factor, with most standards specifying maximum allowable deflection limits to ensure safety and comfort. Slip resistance is paramount for pedestrian walkways and industrial platforms; this is often enhanced through serrated bearing bars or abrasive grit coatings applied during surface treatment, evaluated by friction coefficient tests. Corrosion resistance, largely dependent on the chosen surface treatment (e.g., hot-dip galvanizing, which provides a zinc coating thickness typically between 65-100 microns, or specialized paint systems), determines the grating's longevity in harsh, corrosive environments like offshore platforms or chemical processing facilities. Understanding these parameters and their interplay allows engineers to specify the optimal grating for their project, ensuring structural integrity and operational safety. A professional diamond steel grating factory will have the expertise to guide clients through these technical considerations, offering solutions optimized for performance and cost-effectiveness. The table below presents representative technical data for various types of diamond steel gratings, illustrating how different specifications impact performance characteristics, thereby assisting in informed decision-making processes for industrial procurement and engineering design.

| Grating Type | Bearing Bar (Depth x Thickness) | Bearing Bar Pitch | Cross Bar Pitch | Max Span (Approx. @ 5kN/m² UDL) | Typical Surface Treatment | Primary Application |

|---|---|---|---|---|---|---|

| Standard Duty Welded | 25mm x 3mm | 30mm | 100mm | 1200mm | Hot-Dip Galvanized | Pedestrian Walkways, Light Platforms |

| Heavy Duty Welded | 50mm x 5mm | 40mm | 100mm | 2000mm | Hot-Dip Galvanized | Industrial Platforms, Vehicle Ramps |

| Press-Locked Industrial | 40mm x 5mm | 33mm | 50mm | 1800mm | Hot-Dip Galvanized / Painted | Architectural Features, Trench Covers |

| Serrated Slip-Resistant | 30mm x 3mm | 30mm | 50mm | 1400mm | Hot-Dip Galvanized | Oil & Gas Platforms, Wet Environments |

The detailed parameters, such as the material's yield strength and tensile strength, directly influence the calculated safe working loads. For instance, Q235 steel, a common choice, offers a minimum yield strength of 235 MPa, while Q345 provides 345 MPa, allowing for higher load capacities or lighter designs for the same load. The precision with which these parameters are controlled and tested within a diamond steel grating factory environment directly correlates with the safety coefficients and regulatory compliance of the final product. Finite Element Analysis (FEA) is often employed by advanced diamond steel grating manufacturers during the design phase to simulate load conditions and predict deflection, ensuring that the grating design meets or exceeds specified performance criteria before physical prototyping. This scientific approach to design and manufacturing underscores the expertise and authoritativeness expected from top-tier diamond steel grating factories, providing clients with data-driven assurances of product quality and reliability. The investment in robust engineering and comprehensive testing is what differentiates leading suppliers, offering peace of mind to project managers and facility owners who rely on these gratings for critical infrastructure.

Image: A detailed view of diamond steel grating showcasing precise manufacturing and uniform mesh size, indicative of high-quality production from a reputable manufacturer.

Beyond Fabrication: Diverse Applications and Sector-Specific Advantages of Diamond Steel Grating

The versatility of diamond steel grating extends far beyond its fundamental structural purpose, making it a preferred material across an extensive spectrum of industrial, commercial, and public applications. Its unique design, which optimizes strength-to-weight ratio while allowing for exceptional light, air, and fluid passage, makes it indispensable in environments where safety, ventilation, and maintenance are critical. A leading diamond steel grating factory understands these varied demands and customizes solutions for optimal performance in each specific context. For instance, in the energy sector, including power plants (thermal, nuclear, and renewable energy facilities) and oil & gas refineries, diamond steel grating is extensively used for platforms, walkways, stair treads, and trench covers. Here, the grating’s high load-bearing capacity supports heavy industrial equipment and personnel, while its open structure facilitates heat dissipation and prevents the accumulation of hazardous gases or liquids, crucial for operational safety and regulatory compliance. The hot-dip galvanized finish provides exceptional resistance to corrosive agents commonly found in these environments, ensuring longevity and reducing maintenance cycles.

In the metallurgy and mining industries, where abrasive materials and heavy machinery are prevalent, the robustness and impact resistance of diamond steel grating are highly valued for crushing plant floors, conveyor walkways, and inspection platforms. Its ability to withstand high dynamic loads and resist wear from continuous traffic is essential for maintaining operational efficiency and worker safety. Similarly, in the water treatment and wastewater management sectors, the self-cleaning properties of the open mesh, coupled with superior corrosion resistance, make it ideal for aeration basins, filter press platforms, and channel covers, minimizing clogging and facilitating easy inspection and maintenance. For the shipbuilding and offshore industries, diamond steel grating is critical for deck platforms, engine room access ways, and gangways due to its lightweight nature, excellent drainage capabilities, and resistance to marine environments. Its non-slip surface, especially when serrated, provides secure footing even in wet or oily conditions, a paramount safety feature in maritime operations.

Beyond heavy industry, diamond steel grating finds applications in more architectural and public utility settings. In municipal infrastructure, it is widely used for storm drain covers, tree grates, and public access ramps, offering durability and aesthetic appeal while managing water flow. For commercial buildings and architectural designs, customized diamond grating can serve as distinctive facades, sunscreens, or decorative elements, combining functionality with modern aesthetics. The flexibility offered by a specialist diamond steel grating factory in terms of material grades, panel sizes, and surface finishes allows for seamless integration into diverse design concepts. For example, a recent project for a large-scale data center required custom-fabricated diamond steel grating for raised flooring in server rooms to facilitate airflow and cable management while supporting heavy server racks. The client praised the precise fabrication and timely delivery, noting that the tailored solution significantly enhanced the facility's operational efficiency. Another instance involved supplying high-security diamond grating for perimeter fencing and access points at a utility plant, where the robust structure and climb-resistant design provided superior protection. These diverse applications underscore the critical role of diamond steel grating as a foundational element in safe, efficient, and resilient infrastructure across global industries, demonstrating the extensive experience and problem-solving capabilities inherent in a specialized diamond steel grating factory.

Photograph: Diamond steel grating utilized as robust industrial flooring, highlighting its structural integrity and ventilation capabilities in a demanding factory environment.

Selecting the Optimal Partner: Criteria for Evaluating Diamond Steel Grating Manufacturers and Suppliers

The selection of a reliable diamond steel grating factory is a critical decision that impacts project timelines, safety, and long-term operational costs. For B2B decision-makers, evaluating potential manufacturers goes beyond just price; it encompasses a holistic assessment of their capabilities, quality assurances, and service offerings. One of the foremost criteria is the manufacturer's production capacity and technological infrastructure. A leading diamond steel grating factory will possess modern, automated fabrication lines capable of handling large-volume orders while maintaining consistent precision and adhering to tight deadlines. This includes advanced welding equipment, CNC machinery for accurate cutting and notching, and comprehensive surface treatment facilities (like in-house hot-dip galvanizing plants) that ensure quality control throughout the entire production cycle. The scale of operation reflects their ability to manage complex projects and deliver on time, a crucial factor for large industrial or infrastructure developments where delays can incur significant financial penalties.

Another paramount consideration is the manufacturer's commitment to quality and adherence to international standards. This is best evidenced by certifications such as ISO 9001 (Quality Management System), CE marking (for products sold within the European Economic Area), and compliance with specific industry standards like ASTM A36 for structural steel, ASTM F1387 for grating manufacturing, and ANSI/NAAMM MBG 531-09 for metal bar grating. These certifications are not mere formalities; they represent a rigorous, independently audited commitment to consistent quality control, traceability, and continuous improvement in all manufacturing processes. Furthermore, inquire about their internal quality assurance protocols, including raw material inspection, in-process testing, and final product verification. A reputable diamond steel grating factory will readily provide material test certificates (MTCs), load test reports, and coating thickness reports for their products. Their experience and authoritativeness are often reflected in their service longevity and a portfolio of successfully completed projects in diverse, demanding sectors.

Customization capabilities and engineering support are also vital. Many industrial projects require bespoke grating solutions that cannot be met by standard off-the-shelf products. A top-tier diamond steel grating factory will offer extensive customization options, including specific bearing bar sizes and spacing, unusual panel dimensions, various cutouts and penetrations for pipes or equipment, and specialized surface treatments beyond standard galvanization (e.g., custom paint colors, anti-skid coatings). Their engineering team should be capable of providing technical consultation, design assistance, and even finite element analysis (FEA) to optimize grating designs for specific load requirements and structural integrity. This level of technical partnership ensures that the chosen grating solution is perfectly tailored to the project's unique demands, preventing costly redesigns or compromises during installation. Finally, assess their after-sales support, including warranty policies, technical assistance for installation, and responsiveness to any potential issues. A strong network of customer support and readily available technical experts reflects a manufacturer’s commitment to client satisfaction and product longevity, building trust and fostering long-term partnerships. This comprehensive evaluation framework helps B2B buyers make informed decisions, ensuring they partner with a diamond steel grating factory that delivers not just products, but reliable, high-performance solutions.

Visual: A close-up of a diamond steel grating panel highlighting the precision of fabrication and surface finish, indicative of a quality-certified manufacturer.

Ensuring Longevity and Reliability: Quality Assurance and After-Sales Support from Leading Diamond Steel Grating Factories

The commitment to quality assurance and comprehensive after-sales support is a hallmark of a truly trustworthy diamond steel grating factory. It extends beyond the mere production of steel gratings to encompass a holistic approach to customer satisfaction and product performance over its entire lifecycle. A robust Quality Management System (QMS), often certified to ISO 9001, forms the backbone of their operations. This system mandates stringent checks at every stage, from the reception of raw materials like Cold Rolled Steel Bar to the final dispatch of finished products. Raw materials are verified against specifications through mill certificates and, if necessary, independent laboratory testing to confirm chemical composition and mechanical properties. During the manufacturing process, in-process inspections are conducted to monitor dimensional accuracy, welding integrity (for welded gratings), and the quality of cutting and notching. Robotic welding systems, for instance, are regularly calibrated to ensure consistent weld penetration and minimal heat distortion, critical for maintaining the structural integrity of the diamond pattern.

Upon completion, every batch of diamond steel grating undergoes rigorous final product testing. This includes visual inspection for defects, dimensional checks against design drawings, and critical performance tests such as load-bearing capacity tests, deflection tests, and anti-slip evaluations. For hot-dip galvanized gratings, coating thickness is meticulously measured using specialized equipment to ensure optimal corrosion protection as per industry standards like ASTM A123/A123M. Any product failing to meet these strict criteria is quarantined and addressed, underscoring the factory's unwavering commitment to delivering only top-tier products. This meticulous attention to detail at every phase guarantees that gratings supplied by a leading diamond steel grating factory will meet or exceed the performance expectations in even the most demanding industrial environments, providing an unparalleled level of safety and operational efficiency. The authoritative nature of a manufacturer is not just in their ability to produce, but in their transparent and verifiable quality control processes, which instill confidence in their clientele.

Beyond manufacturing excellence, the mark of a reliable diamond steel grating factory is its dedication to after-sales support. This typically includes comprehensive warranty provisions that cover material and manufacturing defects, offering clients peace of mind. The length and scope of these warranties often reflect the manufacturer's confidence in their product's durability. Furthermore, proactive customer support is crucial. This involves providing detailed installation guides, technical consultation for complex projects, and rapid response to inquiries or unforeseen challenges during project execution. Many leading suppliers offer dedicated technical support teams accessible via multiple channels, ensuring that clients receive timely and expert assistance. For instance, if a project encounters specific site conditions that affect installation, the factory's engineers should be available to provide guidance or suggest modifications. Delivery logistics and lead times are also transparently communicated, with robust supply chain management ensuring on-time delivery even for large or complex orders, minimizing project delays. This holistic approach, from stringent quality control and authoritative certifications to responsive customer service and clear warranty promises, fosters trustworthiness and builds lasting partnerships, making the chosen diamond steel grating factory an indispensable asset to any major industrial or civil engineering project.

Control point: An experienced technician conducting a final quality inspection on diamond steel grating panels before dispatch, ensuring adherence to strict specifications and client requirements.

Client Success Stories and Future Outlook: Paving the Way with Advanced Diamond Steel Grating Solutions

The true measure of a leading diamond steel grating factory lies in the tangible success and satisfaction of its clients across diverse and demanding projects. These success stories are not merely anecdotal; they are empirical validations of the manufacturer's expertise, product reliability, and commitment to customer partnership. For example, a major client in the Middle Eastern oil and gas sector recently undertook an expansion of their offshore drilling platform. They required thousands of square meters of heavy-duty diamond steel grating, specifically engineered for extreme marine corrosion resistance and high load capacity, capable of supporting both heavy equipment and continuous personnel movement. Our selected diamond steel grating factory collaborated closely with their engineering team from the initial design phase, providing bespoke solutions that included specialized anti-slip serrations and a triple-layer marine-grade coating system, exceeding the client’s stringent safety and durability requirements. The project was delivered on schedule, and the client reported significantly reduced installation times due to the precise fabrication and modular design, praising the grating’s exceptional performance under harsh operating conditions, reinforcing their confidence in our supplier's capabilities.

Another notable case involved a large-scale municipal wastewater treatment plant upgrade in North America. The challenge was to replace aging, corroded walkways and trench covers with a durable, maintenance-friendly solution that could withstand constant exposure to corrosive chemicals and moisture. The diamond steel grating factory provided a solution utilizing stainless steel diamond grating with electro-polished finishes, ensuring maximum corrosion resistance and ease of cleaning, which minimized biofilm buildup. The project’s success was further highlighted by the factory’s ability to pre-fabricate panels with complex cutouts for existing pipework and machinery, leading to seamless installation and minimal disruption to the plant's operations. The facility manager noted that the new gratings not only improved safety for their staff but also significantly reduced the need for frequent repairs and replacements, contributing to substantial long-term cost savings. These examples underscore the real-world impact of partnering with a diamond steel grating factory that combines technical prowess with a deep understanding of industry-specific challenges and client needs, consistently delivering solutions that enhance operational safety, efficiency, and longevity.

Looking ahead, the future of diamond steel grating technology is characterized by continuous innovation driven by evolving industry demands and environmental considerations. Emerging trends include the development of lighter, yet stronger, grating solutions through advanced material composites or novel steel alloys with superior mechanical properties. There's also a growing focus on "smart gratings" that could potentially integrate sensors for structural health monitoring, providing real-time data on load, deflection, and corrosion levels, allowing for proactive maintenance and enhanced safety. Furthermore, sustainability will remain a key driver, with manufacturers exploring greener production methods, increased use of recycled materials, and coatings with lower environmental footprints. The push towards modular and easily installable grating systems will also continue, reducing on-site labor costs and accelerating project completion times. A forward-thinking diamond steel grating factory is not content with current achievements but actively invests in R&D, collaborating with academic institutions and industry bodies to push the boundaries of what steel grating can achieve. This proactive approach ensures that they remain at the forefront of providing cutting-edge, high-performance grating solutions that meet the challenges of tomorrow's infrastructure, reaffirming their authoritative position and commitment to industry leadership and client success.

Showcase: An industrial walkway constructed with diamond steel grating, exemplifying its critical function in ensuring safety and accessibility within large-scale operations.

Frequently Asked Questions (FAQ) about Diamond Steel Grating Factories

-

Q1: What types of steel do leading diamond steel grating factories typically use?

Leading diamond steel grating factories primarily utilize high-quality steel grades such as Q235 (equivalent to ASTM A36) and Q345 (equivalent to ASTM A572 Grade 50) for standard applications due to their excellent strength and weldability. For environments requiring superior corrosion resistance, stainless steel grades like 304, 316, or 316L are commonly employed. The choice of steel is critical and is often dictated by the specific load requirements, environmental conditions (e.g., exposure to chemicals, salt water), and project budget, ensuring optimal performance and longevity for the application.

-

Q2: What surface treatments are available for diamond steel grating to enhance durability?

The most common and highly effective surface treatment is hot-dip galvanizing, which provides a robust zinc coating that offers superior corrosion protection and extends the grating’s lifespan significantly, often for several decades in typical industrial environments. Other available treatments include various painting systems (e.g., epoxy, polyurethane, or specialized anti-corrosion paints) for specific aesthetic requirements or chemical resistance, and powder coating, which offers a durable and aesthetically pleasing finish. A professional diamond steel grating factory can advise on the best treatment based on the intended application and environmental exposure.

-

Q3: How do diamond steel grating manufacturers ensure slip resistance?

To ensure high slip resistance, especially in wet, oily, or icy conditions, diamond steel grating manufacturers offer gratings with serrated bearing bars. These bars have notched or tooth-like top surfaces that provide enhanced traction. Additionally, some specialized gratings can be fitted with abrasive grit surfaces, providing an even higher coefficient of friction. Compliance with international standards for slip resistance, such as those defined by ASTM or relevant national safety regulations, is typically verified through specific friction coefficient tests conducted by the diamond steel grating factory or third-party laboratories.

-

Q4: What customization options are available from a diamond steel grating factory?

Leading diamond steel grating factories offer extensive customization options to meet specific project requirements. These include bespoke panel dimensions, various mesh sizes, specific bearing bar sizes (depth and thickness) and spacing, and different cross bar configurations. They can also incorporate complex cutouts, holes, and banding for pipe penetrations, equipment integration, or staircase landings. Furthermore, custom finishes, special material grades (e.g., duplex stainless steel), and the inclusion of toe plates or special fixings can be provided upon request, ensuring the grating fits perfectly into the project’s design.

-

Q5: What is the typical delivery timeline for custom diamond steel grating orders?

Delivery timelines for custom diamond steel grating orders can vary significantly based on the complexity, volume, and current production schedule of the diamond steel grating factory. Generally, lead times can range from 2 to 4 weeks for standard custom orders, while very large or highly specialized projects might require 6-8 weeks or more. Reputable manufacturers will provide clear and realistic timelines during the quotation phase and maintain transparent communication throughout the production process, informing clients of any potential adjustments to ensure efficient project planning and execution. Expedited options may be available for urgent requirements.

-

Q6: How does a diamond steel grating factory ensure compliance with international safety standards?

A responsible diamond steel grating factory ensures compliance through multiple layers of quality assurance and certification. This includes adherence to internationally recognized manufacturing standards like ISO 9001 (Quality Management System) and product-specific standards such as ASTM F1387 (Standard Specification for Metal Bar Grating), ANSI/NAAMM MBG 531-09 (Metal Bar Grating Manual), and relevant European or local building codes. They conduct internal testing (load capacity, deflection, slip resistance) and often engage independent third-party laboratories for verification. Providing official test reports and material certificates is standard practice, demonstrating their authoritative commitment to safety and regulatory compliance.

-

Q7: What kind of warranty and customer support can I expect?

Leading diamond steel grating factories typically offer comprehensive warranties covering manufacturing defects and material integrity for a specified period, often ranging from 1 to 5 years, depending on the product and application. Beyond the warranty, you can expect robust customer support, including technical assistance for product selection, installation guidance, and troubleshooting. Many factories provide dedicated account managers and technical teams accessible via phone or email, ensuring prompt and expert responses to inquiries, reinforcing their trustworthiness and commitment to long-term client relationships.

References and Further Reading:

- ASTM International: "Standard Specification for Steel Bar Grating, Welded, Press Locked, or Mechanically Locked." Available at: https://www.astm.org/

- National Association of Architectural Metal Manufacturers (NAAMM): "Metal Bar Grating Manual (ANSI/NAAMM MBG 531-09)." This provides comprehensive guidelines for the design, fabrication, and installation of metal bar grating. Available at: https://www.naamm.org/

- NACE International (AMPP): "Corrosion Basics: An Introduction." Offers fundamental understanding of corrosion mechanisms and prevention methods relevant to steel structures. Available at: https://www.ampp.org/

- ISO (International Organization for Standardization): "ISO 9001: Quality management systems – Requirements." Essential for understanding quality assurance in manufacturing processes. Available at: https://www.iso.org/standards/iso-9001-quality-management.html

- Galvanizers Association: "The Durability of Hot Dip Galvanizing." Provides insights into the lifespan and protective qualities of galvanized coatings. Available at: https://www.galvanizing.org.uk/

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Cost-Effective

NewsAug.10,2025

-

Leading Diamond Steel Grating Factory - Durable & Custom

NewsAug.10,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Durable, Versatile, Reliable

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen | Durable Fencing Solution

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable, Versatile, Cost-Effective

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd. | Durable, Versatile, Reliable

NewsAug.09,2025