ئىيۇل . 23, 2025 11:48 تىزىملىككە قايتىش

Hexagonal Wire Mesh Innovations for Coastal Protection Projects

Coastal regions worldwide face increasing threats from erosion, storm surges, and rising sea levels. Traditional methods like concrete seawalls and rock revetments are often costly, environmentally disruptive, and inflexible. In response, engineers and environmentalists are turning to innovative solutions such as hexagonal wire mesh systems. These versatile materials combine durability, adaptability, and eco-friendliness, making them ideal for modern coastal protection projects. This article explores four groundbreaking applications of hexagonal wire mesh technology, focusing on توقۇلغان ئالتە تەرەپلىك سىم تور, PVC hexagonal mesh wire fences, سۇلياۋ يوپۇق ئالتە تەرەپلىك سىم تور, and their role in safeguarding shorelines.

Woven Hexagonal Wire Mesh: Engineering Resilience Against Erosion

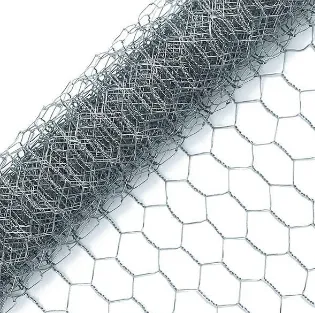

Woven hexagonal wire mesh is a cornerstone of coastal protection due to its unique structural integrity. Crafted from galvanized steel wires twisted into hexagonal patterns, this mesh offers exceptional tensile strength and flexibility. Unlike rigid barriers, it conforms to natural contours, reducing stress points and enhancing longevity.

In coastal projects, توقۇلغان ئالتە تەرەپلىك سىم تور is often filled with stones or organic materials to create gabions. These gabion structures dissipate wave energy, stabilize slopes, and prevent sediment loss. For example, in mangrove restoration initiatives, gabions made with توقۇلغان ئالتە تەرەپلىك سىم تور act as temporary barriers, allowing vegetation to take root while shielding saplings from tidal forces.

The mesh’s open design also promotes ecological balance. Water flows freely through the gaps, minimizing disruption to marine life and sediment transport. Additionally, its corrosion-resistant galvanized coating ensures decades of service in saltwater environments, making it a cost-effective, sustainable choice for large-scale projects.

PVC Hexagonal Mesh Wire Fences: Combating Coastal Debris and Habitat Protection

PVC hexagonal mesh wire fences are revolutionizing how coastal zones manage debris and protect fragile ecosystems. These fences consist of hexagonal wire mesh panels coated with polyvinyl chloride (PVC), adding a layer of resistance to saltwater corrosion, UV radiation, and abrasion.

Deployed along vulnerable shorelines, PVC hexagonal mesh wire fences act as barriers against floating debris, such as plastics and driftwood, which can damage habitats or exacerbate erosion. Their lightweight yet robust design allows for quick installation, even in remote areas. In turtle nesting sites, for instance, these fences prevent human interference while allowing hatchlings to pass through safely.

The PVC coating also enhances visibility, reducing the risk of entanglement for wildlife. Unlike traditional metal fences, the non-conductive nature of PVC hexagonal mesh wire fences makes them safe for use near electrical infrastructure or in areas prone to lightning strikes.

Hexagonal Wire Mesh: Adaptive Solutions for Dynamic Shorelines

The versatility of hexagonal wire mesh lies in its adaptability to diverse coastal challenges. From reinforcing dunes to creating artificial reefs, its applications are limited only by engineering creativity.

In dune stabilization, layers of hexagonal wire mesh are embedded into sand to anchor vegetation and prevent wind erosion. Over time, native grasses grow through the mesh, creating a natural barrier against storm surges. Similarly, submerged hexagonal wire mesh structures serve as artificial reefs, promoting coral growth and marine biodiversity. These reefs not only protect coastlines but also revive fisheries and tourism economies.

For temporary flood defenses, hexagonal wire mesh barriers filled with sand or gravel can be rapidly deployed during emergencies. Their modular design allows for easy reconfiguration, ensuring resources are used efficiently across multiple projects.

Plastic Coated Hexagonal Wire Mesh: Enhancing Durability in Harsh Environments

Plastic coated hexagonal wire mesh takes corrosion resistance to the next level. By enveloping galvanized steel wires in a polyethylene or PVC layer, this mesh withstands prolonged exposure to saltwater, acidic rain, and abrasive sands.

Coastal infrastructure such as breakwaters and groynes benefit immensely from سۇلياۋ يوپۇق ئالتە تەرەپلىك سىم تور. The coating prevents rust, reducing maintenance costs and extending service life. In tropical regions, where UV degradation is a concern, the plastic layer also protects against color fading and brittleness.

Another innovative use is in floating barriers. Plastic coated hexagonal wire mesh panels attached to buoyant frames create flexible breakwaters that attenuate wave energy without obstructing water circulation. These systems are particularly effective in protecting marinas, aquaculture farms, and low-lying communities.

FAQs About Hexagonal Wire Mesh Solutions

How does woven hexagonal wire mesh compare to traditional concrete in coastal projects?

Woven hexagonal wire mesh offers superior flexibility and environmental compatibility. Unlike concrete, it allows natural water flow and vegetation growth, reducing ecological disruption while maintaining structural stability.

Can PVC hexagonal mesh wire fences withstand hurricane-force winds?

Yes, PVC hexagonal mesh wire fences are designed to endure extreme weather. Their combination of flexible hexagonal wire mesh and impact-resistant PVC ensures durability even in Category 4 storms.

What is the lifespan of plastic coated hexagonal wire mesh in saltwater?

Properly installed سۇلياۋ يوپۇق ئالتە تەرەپلىك سىم تور can last over 25 years in marine environments, thanks to its dual-layer protection against corrosion and physical wear.

Are hexagonal wire mesh solutions customizable for complex terrains?

Absolutely. Manufacturers provide tailored dimensions, wire gauges, and coating options to suit specific project needs, from curved shorelines to steep cliffs.

Do hexagonal wire mesh products require specialized maintenance?

Routine inspections for debris accumulation or coating damage are sufficient. Their low-maintenance design makes them ideal for remote or large-scale installations.

From erosion control to habitat preservation, hexagonal wire mesh innovations are redefining coastal protection. Products like توقۇلغان ئالتە تەرەپلىك سىم تور, PVC hexagonal mesh wire fences, and سۇلياۋ يوپۇق ئالتە تەرەپلىك سىم تور offer scalable, sustainable solutions that balance human needs with environmental stewardship. As climate challenges intensify, these adaptable systems will play a pivotal role in safeguarding our shores for generations to come.

-

How PVC Welded Wire Mesh Enhances Industrial Safety Standards

خەۋەرلەرJul.23,2025

-

Hexagonal Wire Mesh Innovations for Coastal Protection Projects

خەۋەرلەرJul.23,2025

-

Galvanized Wire Fence Maintenance Tips for Harsh Weather Conditions

خەۋەرلەرJul.23,2025

-

Galvanized Steel Grating Applications in Industrial Flooring Solutions

خەۋەرلەرJul.23,2025

-

Energy Absorption Capabilities of Twisted Square Bars in Seismic-Resistant Structures

خەۋەرلەرJul.23,2025

-

Affordable Chain Link Fence Gate Options for Residential Security

خەۋەرلەرJul.23,2025