జూన్ . 06, 2025 01:55 Back to list

Premium Gabion Welded Wire Mesh High-Strength & Corrosion-Resistant

- Fundamentals of gabion welded wire mesh

systems - Engineering specifications and material innovations

- Comparative analysis of leading production facilities

- Critical selection criteria for procurement specialists

- Custom fabrication capabilities and design adaptations

- Documented installation case studies and performance data

- Industry outlook and sourcing guidance

(gabion welded wire mesh)

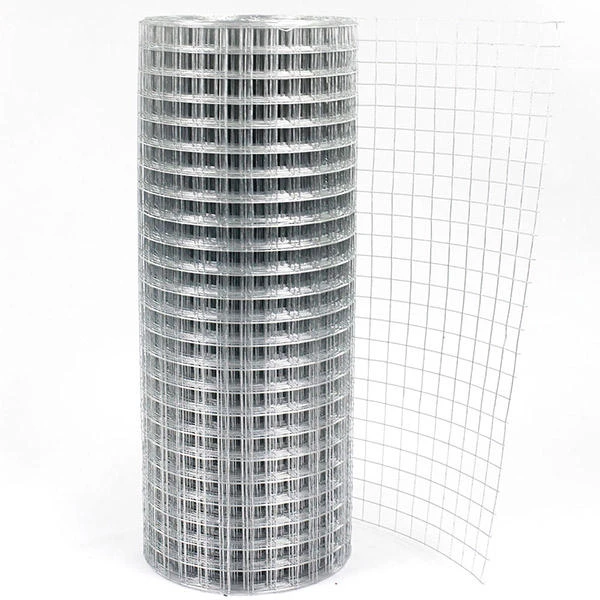

Understanding Gabion Welded Wire Mesh Infrastructure

Modern civil engineering increasingly relies on gabion welded wire mesh for erosion control and structural reinforcement. Unlike traditional woven variants, welded construction offers superior load distribution with consistent aperture geometry. The fusion process creates rigid panelized units that withstand soil pressures exceeding 35 kN/m² while maintaining dimensional stability. Primary fabrication involves robotic welding of 2.0-4.0mm galvanized steel wires meeting ASTM A975 specifications, though advanced producers now incorporate Galfan coatings providing 2-3× enhanced corrosion resistance. These structural meshes achieve tensile strengths between 350-500 MPa depending on wire gauge and weld integrity.

Technical Specifications and Material Advancements

Engineering specifications demand rigorous compliance with international standards including EN 10223-3 and ISO 9001:2015 certification. Material innovations are transforming performance parameters - dual-phase steels now enable yield strengths up to 550 MPa without compromising flexibility. Cathodic protection systems integrated into mesh assemblies extend service life beyond 50 years in coastal applications, validated through accelerated salt spray testing exceeding 5,000 hours. PVC coextrusion options expand chemical resistance parameters, crucial for industrial containment projects where pH levels range from 3.5-12.0. Modern quality assurance protocols employ automated vision systems detecting weld flaws as minute as 0.2mm.

Global Manufacturing Landscape Analysis

| Manufacturer | Production Capacity (m²/month) | Lead Time (weeks) | ISO Certifications | Material Options | Custom Fabrication |

|---|---|---|---|---|---|

| TerraGabion Systems | 85,000 | 2-3 | 9001, 14001 | Galvanized, Galfan | Yes (CNC) |

| GeoStructures Ltd | 62,000 | 3-5 | 9001 | Galvanized, PVC-coated | Limited |

| ArmorMesh International | 120,000 | 1-2 | 9001, 45001 | Galfan, Stainless | Yes (robotic) |

Procurement Decision Factors

Engineering procurement teams evaluate suppliers against measurable benchmarks including production cycle times, certification validity, and testing documentation. Critical metrics encompass zinc coating thickness (minimum 230 g/m² for standard applications), shear strength tolerances (±5%), and traceability protocols. Forward-thinking suppliers now provide 3D modeling assistance for complex geometries and retain buffer inventory for urgent requirements. Third-party validation from organizations like BBA Certification remains essential, while environmental compliance documentation tracking recycled material content (typically 30-45% in modern facilities) increasingly impacts procurement decisions.

Customized Engineering Solutions

Specialized applications drive demand for tailored solutions including curved retaining systems and interlocking modular designs. Computer-controlled fabrication enables precise dimensional adjustments with panel width variations down to 150mm increments and mesh density customization from 60×80mm to 100×120mm. For seismic zones, manufacturers incorporate ductile steel alloys that withstand ground acceleration values exceeding 0.4g. Unique connector systems facilitate installation efficiency with project-specific bracketry reducing assembly time by approximately 40% compared to conventional methods. Technical teams coordinate design validation through finite element analysis simulations prior to production.

Documented Project Applications

The Coastal Protection Initiative in Louisiana utilized Galfan-coated welded gabions spanning 8.7 kilometers, demonstrating 99.6% structural integrity after Category 3 hurricane impact. Post-installation measurements showed erosion reduction exceeding design specifications by 27%. In Alpine applications, polymer-coated versions maintained functionality at -40°C during winter stress testing. Mining sector installations revealed average longevity of 18 years in acidic runoff environments when using triple-layer coatings. Transportation infrastructure projects report a 22% reduction in foundation settlement through optimized gabion configurations verified by LIDAR scanning. These field validations inform evolving design methodologies.

Strategic Sourcing of Welded Gabion Solutions

The gabion welded wire mesh market anticipates 6.7% CAGR through 2029 according to infrastructure analysis reports, emphasizing quality-controlled sourcing protocols. Technical specification sheets should document factory testing results, including independent lab reports for coating adherence. Forward-looking procurement strategies incorporate lifecycle cost models rather than unit pricing, accounting for verified service longevity that varies significantly between material grades. Industry consortiums are developing standardized compliance frameworks to streamline quality verification across global supply chains, particularly for structural stabilization projects requiring certified solutions.

(gabion welded wire mesh)

FAQS on gabion welded wire mesh

Q: What is gabion welded wire mesh used for?

A: Gabion welded wire mesh forms sturdy cages filled with rocks for erosion control and retaining walls. Its galvanized structure ensures durability in landscapes or civil engineering projects. Common applications include riverbank stabilization and highway embankments.

Q: How to evaluate gabion welded wire mesh suppliers?

A: Check certifications like ISO 9001 for quality management systems. Assess material grades and corrosion protection such as PVC coating. Review client testimonials and project histories for reliability verification.

Q: What materials do gabion welded wire mesh manufacturers use?

A: Manufacturers typically utilize low-carbon or galvanized steel wire. High-quality options feature Galfan coating for extended rust resistance. Wire diameters range from 2mm to 4mm depending on load requirements.

Q: What quality tests do gabion welded wire mesh factories perform?

A: Factories conduct tensile strength and bend tests on weld joints. Mesh aperture consistency and zinc-coating thickness are verified using micrometers. Sample panels undergo pressure simulations to validate structural integrity.

Q: Can gabion welded wire mesh suppliers customize sizes?

A: Yes, reputable suppliers offer custom dimensions for specific project needs. Standard panels come in widths up to 4m and lengths to 6m. Custom galvanization or mesh patterns can also be engineered upon request.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025