ఆగ . 08, 2025 01:40 Back to list

100x100cm Square Reinforcing Mesh - Direct Factory Supply

In the rapidly evolving landscape of modern construction, the demand for robust, reliable, and efficient building materials is paramount. Among these, reinforcing mesh stands out as a critical component for enhancing the structural integrity of concrete elements. This article delves into the specifics of 100x100 cm square reinforcing mesh product factory operations, exploring their role, technological advancements, and the significant advantages they offer. As a leading 100x100 cm square reinforcing mesh product factory, we are committed to providing insights into the quality, precision, and innovation that define this essential construction material.

Industry Trends and Market Dynamics for Reinforcing Mesh

The global construction market is experiencing unprecedented growth, driven by urbanization, infrastructure development, and increased investment in residential and commercial sectors. This surge directly impacts the demand for reinforcing materials like the 100x100 cm square mesh. Key trends include:

- Sustainable Construction: Growing emphasis on eco-friendly materials and processes, leading to the adoption of recycled steel and optimized production methods.

- Digitalization & Automation: Integration of BIM (Building Information Modeling) and automated manufacturing processes in 100x100 cm square reinforcing mesh product manufacturers to improve precision, reduce waste, and enhance efficiency.

- High-Strength Materials: Demand for mesh products with higher tensile and yield strengths to meet stringent structural requirements and reduce material volume.

- Customization: Increased need for tailor-made mesh sizes and specifications to optimize project costs and timelines.

According to a recent report by Grand View Research, the global reinforcing mesh market size was valued at USD 8.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030, highlighting the robust growth trajectory for this sector. This strong market outlook underscores the importance of choosing reliable 100x100 cm square reinforcing mesh product suppliers.

Technical Parameters of 100x100 cm Square Reinforcing Mesh

The "100x100 cm" refers to the square grid spacing of the mesh, which is a common and highly effective configuration for distributing load and preventing cracking in concrete slabs, walls, and foundations. Key technical parameters define the performance and suitability of this product:

- Mesh Size: 100mm x 100mm (or 10cm x 10cm). This uniform spacing ensures consistent load transfer and crack control.

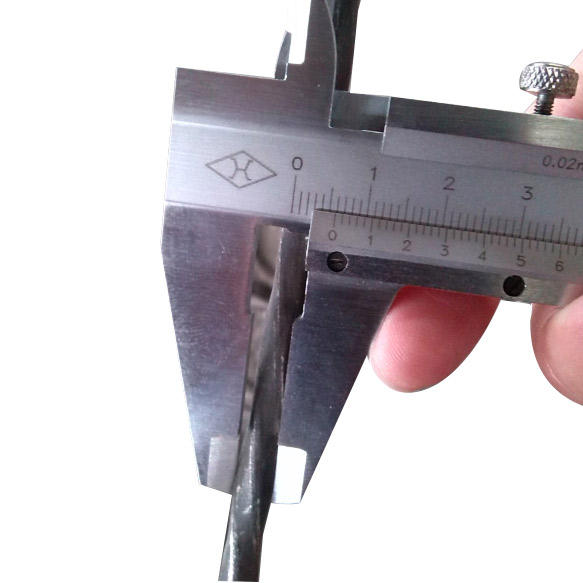

- Wire Diameter: Typically ranges from 4mm to 12mm, with common sizes being 5mm, 6mm, 8mm, and 10mm. The choice depends on the structural load and concrete thickness.

- Material Grade: Usually high-tensile steel wire, such as Grade 500B (equivalent to ASTM A615 Grade 60 or BS 4449 Grade B500B). This provides excellent strength-to-weight ratio.

- Tensile Strength: The maximum stress the material can withstand before breaking. For Grade 500B, it's typically 550 MPa (MegaPascals).

- Yield Strength: The stress at which the material begins to deform plastically. For Grade 500B, it's 500 MPa. This is a critical parameter for structural design.

- Sheet Dimensions: Standard sheet sizes often include 2.4m x 4.8m or custom dimensions based on project requirements.

- Weight per Square Meter: Varies significantly based on wire diameter and mesh size. For a 100x100 mm mesh with 6mm wires, the weight is approximately 3.7 kg/m².

The precise engineering of these parameters ensures optimal performance. Here's a comparative table of typical specifications from a leading 100x100 cm square reinforcing mesh product factory:

| Parameter | Standard (Metric) | Typical Range | Notes |

|---|---|---|---|

| Mesh Opening Size | 100mm x 100mm | 50x50mm to 200x200mm | Common for slab reinforcement. |

| Wire Diameter (d) | 5mm - 10mm | 4mm - 12mm | Determines strength. |

| Material Grade | Grade 500B (B500B) | Grade 250, 460, 500 | High yield strength steel. |

| Yield Strength (min) | 500 MPa | 250-500 MPa | Critical for structural design. |

| Tensile Strength (min) | 550 MPa | 400-600 MPa | Resistance to breaking. |

| Elongation at Break (min) | 5% - 8% | 5% - 12% | Ductility. |

| Standard Sheet Size | 2.4m x 4.8m | Custom sizes available. | Efficient for large areas. |

Application Scenarios of 100x100 cm Square Reinforcing Mesh

The versatility of 100x100 cm square reinforcing mesh makes it indispensable across a multitude of construction applications, from residential projects to heavy industrial infrastructure. Its primary function is to distribute tensile stress within concrete, preventing cracking and enhancing load-bearing capacity.

- Concrete Slabs: Widely used in ground slabs for residential, commercial, and industrial buildings, including driveways, patios, and warehouse floors. It ensures even load distribution and prevents thermal cracking.

- Foundations: Integral to the structural integrity of raft foundations, strip footings, and retaining walls, providing essential reinforcement against differential settlement and hydrostatic pressure.

- Roads & Pavements: Utilized in concrete roads, airport runways, and heavy-duty pavements to withstand traffic loads and minimize crack propagation due to fatigue.

- Pre-fabricated Elements: Incorporated into precast concrete components such as panels, beams, and columns, enabling faster construction and higher quality control.

- Mining & Tunnelling: Employed as ground support in tunnels and mines, offering rockfall protection and enhancing the stability of excavated areas.

- Agricultural Structures: Used in shed floors, silage pits, and other farm infrastructure requiring durable concrete surfaces.

Its ease of installation and ability to conform to various shapes make it a preferred choice for architects and engineers globally. The consistency offered by a reputable 100x100 cm square reinforcing mesh product factory ensures reliable performance in these diverse scenarios.

Technical Advantages and Benefits

Beyond its fundamental role in reinforcement, 100x100 cm square reinforcing mesh offers several compelling technical advantages that contribute to cost-effectiveness, durability, and project efficiency:

- Superior Crack Control: The small, uniform mesh opening effectively distributes stress, minimizing the formation and propagation of cracks caused by drying shrinkage, thermal expansion/contraction, and structural loads.

- Enhanced Structural Integrity: Increases the flexural strength and overall load-bearing capacity of concrete, making structures more resilient to heavy loads and seismic activity.

- Reduced Construction Time & Labor: Pre-fabricated mesh sheets significantly reduce on-site cutting, bending, and tying of individual rebar. This accelerates installation, lowers labor costs, and improves project timelines.

- Consistency & Quality: Factory-produced mesh ensures precise wire spacing and welding quality, eliminating variations often found in manual rebar installation. This adherence to strict standards, often ISO 9001 certified, guarantees reliable performance from every 100x100 cm square reinforcing mesh product factory.

- Cost Efficiency: While initial material costs might vary, the overall project cost savings from reduced labor, faster concrete pouring, and minimized material waste make mesh a highly economical choice.

- Optimized Material Usage: High-strength mesh allows for the use of thinner concrete sections in some applications, reducing concrete volume and overall dead load.

- Corrosion Resistance (Optional): For specific applications, the mesh can be galvanized or epoxy-coated, significantly extending its service life in corrosive environments (e.g., coastal areas, industrial facilities). This enhancement contributes to a longer product lifespan, often exceeding 50-70 years in typical applications, making it ideal for industries like petrochemical, marine, and wastewater treatment.

The advantages are clear: a well-manufactured 100x100 cm square reinforcing mesh from a reputable 100x100 cm square reinforcing mesh product factory offers not just reinforcement, but a pathway to more efficient, durable, and cost-effective construction.

Manufacturer Comparison: Choosing the Right 100x100 cm Square Reinforcing Mesh Product Factory

Selecting the right **100x100 cm square reinforcing mesh product factory** is crucial for project success. While many suppliers exist, discerning buyers look beyond just price. Here's what sets leading manufacturers apart:

- Quality Certifications: Look for factories with internationally recognized certifications like ISO 9001 for quality management, and adherence to specific product standards such as ASTM A1064/A1064M (Standard Specification for Carbon-Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete), BS 4483 (Steel fabric for the reinforcement of concrete), or AS/NZS 4671 (Steel reinforcing materials). Our factory proudly adheres to these stringent global standards.

- Raw Material Sourcing: Top manufacturers use prime quality, certified high-tensile steel wire coils. Transparency in sourcing ensures product integrity and traceability. We partner with established steel mills to guarantee consistent material quality.

- Manufacturing Technology: Advanced automatic welding lines (e.g., resistance welding) ensure strong, consistent welds and precise mesh dimensions. Older, less sophisticated equipment can lead to variations in mesh size and weld strength.

- Capacity & Lead Times: A large, well-equipped 100x100 cm square reinforcing mesh product factory can handle large orders efficiently, offering shorter and more reliable delivery schedules. We maintain substantial inventory and production capacity to meet urgent demands.

- Customization Capabilities: The ability to produce mesh in non-standard sizes, wire diameters, or with specific coatings (e.g., galvanized, epoxy) is a significant advantage for complex projects.

- Technical Support & Experience: A manufacturer with deep industry experience (e.g., 20+ years in operation) can offer valuable technical advice, engineering support, and problem-solving assistance. Our team comprises seasoned experts dedicated to client success.

- Reputation & Client Feedback: Positive client testimonials, repeat business, and a strong market reputation are indicators of a reliable supplier. We pride ourselves on long-standing relationships with major construction firms and our consistent track record of excellence.

Our Manufacturing Process Explained: From Wire to Reinforcing Mesh

As a leading 100x100 cm square reinforcing mesh product factory, our commitment to quality starts with a meticulously controlled manufacturing process. Our product, the Twisted Square Bar, is a testament to this precision.

Manufacturing Process Flow:

-

Raw Material Inspection (Steel Wire Rods):

Incoming high-carbon steel wire rods are rigorously inspected for chemical composition, tensile strength, and surface defects (e.g., rust, scale) to meet ASTM A615 or equivalent standards. (Key Node: Material Purity & Strength Verification)

-

Wire Drawing:

The wire rods are drawn through a series of dies to achieve the precise final wire diameter (e.g., 5mm, 6mm, 8mm). This "cold drawing" process significantly increases the tensile and yield strength of the steel, making it ideal for reinforcement. (Key Node: Diameter & Strength Optimization)

-

Straightening & Cutting:

The drawn wire is fed into automated machines that straighten it and cut it to the required length for both longitudinal and transverse wires. Precision is critical here to ensure mesh dimension accuracy. (Key Node: Dimensional Accuracy)

-

Resistance Welding (Automated Mesh Production):

Longitudinal and transverse wires are fed into a highly automated resistance welding machine. At each intersection, a precise electrical current creates localized heat and pressure, forming a strong, durable weld. This is a crucial step that ensures the structural integrity of the mesh. Our machines can produce mesh with the exact 100x100 cm spacing reliably. (Key Node: Weld Strength & Grid Consistency)

-

Quality Control & Inspection:

Each mesh sheet undergoes stringent quality control. This includes visual inspection for weld integrity, measurement of mesh opening and wire diameter, and destructive testing for weld shear strength and tensile properties. Adherence to ISO standards (e.g., ISO 15630-2 for mesh testing) and national standards (e.g., ANSI/AWS D1.4 for structural welding) is strictly maintained. (Key Node: Performance Verification)

-

Surface Treatment (Optional):

For enhanced corrosion resistance, mesh can be hot-dip galvanized or epoxy-coated. This extends the product's lifespan, especially in harsh environments, reducing maintenance costs and ensuring long-term durability, crucial for applications in petrochemical or marine settings. (Key Node: Durability Enhancement)

-

Packaging & Dispatch:

Finished mesh sheets are stacked, bundled, and securely packaged to prevent damage during transit. They are then dispatched to construction sites worldwide. (Key Node: Safe Delivery)

You can visualize a typical mesh manufacturing process through this schematic: [Click for Process Diagram] (Please note: This is a placeholder link for illustrative purposes only. A real diagram or video would be inserted here).

Customization Solutions from a Leading 100x100 cm Square Reinforcing Mesh Product Factory

While 100x100 cm is a standard, many projects require specific adjustments. As an adaptable 100x100 cm square reinforcing mesh product factory, we offer comprehensive customization solutions:

- Non-Standard Dimensions: We can produce mesh sheets in lengths and widths tailored to your project's precise footprint, minimizing waste and site cutting.

- Varied Wire Diameters: While 100x100 cm spacing is fixed, the wire diameter can be varied (e.g., 4mm, 5mm, 6mm, 8mm, 10mm, 12mm) to meet specific load-bearing requirements.

- Dual-Directional Wire Gauges: For highly optimized designs, we can produce mesh with different wire diameters in the longitudinal and transverse directions.

- Special Coatings: Hot-dip galvanization for superior corrosion resistance or epoxy coatings for chemical resistance can be applied, extending the lifespan in aggressive environments.

- Deformed vs. Plain Wire: While standard mesh uses plain wires, we can supply mesh made from deformed wires (ribbed) for enhanced mechanical bond with concrete, increasing shear strength.

- Project-Specific Consultations: Our engineering team works closely with clients to understand project specifications and recommend the most suitable mesh configuration, optimizing both performance and cost.

Real-World Application Cases & Client Feedback

Our extensive experience as a leading 100x100 cm square reinforcing mesh product factory is reflected in numerous successful projects across various sectors. We take pride in our service record spanning over two decades, delivering high-quality mesh solutions globally.

Case Study 1: Large-Scale Industrial Warehouse Flooring

Client: Major Logistics Corporation, Europe

Project Scope: Over 100,000 sq. meters of heavy-duty concrete flooring for a new logistics hub. The floor needed to withstand significant point loads from forklifts and continuous heavy traffic.

Our Solution: We supplied thousands of sheets of 100x100 cm square reinforcing mesh with 8mm wire diameter (Grade 500B). Our ability to deliver large volumes on schedule and provide technical support for laying plans was critical. The client reported a 15% reduction in labor time compared to traditional rebar methods and excellent crack resistance after two years of operation. "The precision and consistency of their mesh made installation incredibly smooth. We've seen no signs of significant cracking, even under heavy load," says the project manager.

Case Study 2: Coastal Residential Development Foundations

Client: Boutique Property Developer, Australia

Project Scope: Foundations for 50 luxury beachfront villas, requiring exceptional corrosion resistance due to the saline environment.

Our Solution: We provided custom-sized 100x100 cm square mesh with 6mm wires, hot-dip galvanized for superior long-term performance against corrosion. Our expertise in galvanized products ensured the mesh met the stringent longevity requirements. The developer highlighted the ease of handling and the confidence in the product's lifespan, which reduced long-term maintenance concerns. This demonstrates our strength as a reliable 100x100 cm square reinforcing mesh product factory for specialized needs.

Frequently Asked Questions (FAQ) about 100x100 cm Square Reinforcing Mesh

Q1: What is the primary purpose of 100x100 cm square reinforcing mesh?

A1: Its primary purpose is to provide tensile strength to concrete, which is inherently strong in compression but weak in tension. The mesh helps control cracking caused by drying shrinkage, thermal stresses, and external loads, ensuring the long-term structural integrity of concrete elements like slabs, walls, and foundations. It acts as a stress distributor, preventing localized stress concentrations.

Q2: What material is typically used for this mesh, and what are its properties?

A2: It is typically made from cold-drawn, high-tensile steel wire, often corresponding to Grade 500B (equivalent to ASTM A1064/A1064M or BS 4483). This steel offers a minimum yield strength of 500 MPa and a tensile strength of 550 MPa, providing excellent reinforcement capabilities and ductility to withstand deformation without brittle failure.

Q3: How does resistance welding contribute to the mesh's quality?

A3: Resistance welding is an automated process where electric current and pressure fuse the wires at their intersections. This creates strong, consistent, and uniform welds, crucial for the mesh's structural performance. It eliminates the inconsistencies of manual tying and ensures precise grid spacing, leading to a superior final product from a reliable 100x100 cm square reinforcing mesh product factory.

Q4: What are the common wire diameters available for 100x100 cm mesh?

A4: Common wire diameters range from 4mm to 12mm. The most frequently used are 5mm, 6mm, 8mm, and 10mm. The selection of wire diameter depends on the specific structural requirements, anticipated loads, and thickness of the concrete member.

Q5: What are the benefits of using pre-fabricated mesh over traditional rebar?

A5: Pre-fabricated mesh offers significant benefits including faster installation, reduced labor costs, consistent quality, minimized material waste, and precise spacing. It also helps in achieving a more uniform concrete cover, enhancing durability. For contractors and project managers, this translates to faster project completion and predictable material costs.

Q6: Can this mesh be used in corrosive environments, and how?

A6: Yes, for corrosive environments like coastal areas, chemical plants, or wastewater treatment facilities, the mesh can be hot-dip galvanized or epoxy-coated. These surface treatments create a protective barrier against rust and chemical attack, significantly extending the mesh's lifespan and maintaining its structural integrity over decades.

Q7: What quality standards should I look for when purchasing from a 100x100 cm square reinforcing mesh product factory?

A7: Always look for certifications such as ISO 9001 for quality management systems. Furthermore, ensure the product complies with relevant international standards like ASTM A1064/A1064M (USA), BS 4483 (UK), or AS/NZS 4671 (Australia/New Zealand). These certifications and standards guarantee that the mesh meets strict specifications for material properties, dimensions, and weld strength.

Trustworthiness: Warranty, Delivery, and Customer Support

As a professional 100x100 cm square reinforcing mesh product factory, our commitment extends beyond just manufacturing. We build trust through transparent policies and dedicated support:

- Quality Assurance & Warranty: All our products, including the Twisted Square Bar, come with a comprehensive material and manufacturing defect warranty, typically ranging from 5 to 10 years, ensuring peace of mind for our clients. We stand behind our products' performance and compliance with stated specifications.

- Delivery & Logistics: We understand the critical nature of timely deliveries in construction. Our optimized logistics network ensures reliable and efficient delivery, with standard lead times of 2-4 weeks for typical orders and expedited options available for urgent requirements. Our robust supply chain management minimizes delays.

- Customer Support: Our dedicated customer service team and technical experts are available to assist with product selection, order tracking, technical queries, and post-sales support. We provide detailed installation guidelines and site assistance when required.

- Certifications & Compliance: Our factory is ISO 9001 certified, and our products consistently meet or exceed international standards like ASTM, BS, and EN specifications. Test certificates are provided with every batch, validating material properties and weld strength.

Conclusion: Partnering with a Premier 100x100 cm Square Reinforcing Mesh Product Factory

The 100x100 cm square reinforcing mesh is a cornerstone of modern concrete construction, offering unparalleled strength, durability, and efficiency. Choosing an experienced and reputable 100x100 cm square reinforcing mesh product factory is not just about procurement; it's about partnering with a specialist who understands your project's demands and delivers solutions that exceed expectations.

At Building Wire Mesh, we are dedicated to setting the benchmark for quality and service in the industry. Our commitment to advanced manufacturing processes, stringent quality control, and comprehensive customer support ensures that every sheet of mesh you receive contributes to the longevity and integrity of your structures. Explore our range, including the robust Twisted Square Bar, and experience the difference that true expertise makes.

Further Reading and References:

- Grand View Research - Reinforcing Mesh Market Size, Share & Trends Analysis Report: https://www.grandviewresearch.com/industry-analysis/reinforcing-mesh-market-report

- ASTM International - Standards for Reinforcing Steel: https://www.astm.org/products-services/standards-and-publications/standards/material-categories/steel/rebar-reinforcing-steel-standards.html

- Concrete Construction Magazine - Benefits of Welded Wire Reinforcement: https://www.concreteconstruction.net/how-to/materials/the-benefits-of-welded-wire-reinforcement_o

-

Chain Link Fence: Comprehensive Guide to Features, Applications, and Specifications - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.08,2025

-

100x100cm Square Reinforcing Mesh - Direct Factory Supply

NewsAug.08,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Chain Link Fence - Durable, Versatile Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Chain Link Fence: Durable, Versatile, Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Galvanized Steel Fence Factory: Durable & Rust-Proof Fencing

NewsAug.07,2025