பிப் . 16, 2025 16:44 Back to list

welded wire mesh for industry manufacturer

OEM low carbon soft galvanised wires are revolutionizing the industrial and manufacturing sectors with their remarkable adaptability and efficiency. These wires, crafted meticulously from low carbon steel, allow for a broad spectrum of uses across various niches, including construction, agriculture, and engineering. Their innovative design not only ensures durability but also aligns with eco-friendly initiatives, making them a go-to choice for businesses keen on maintaining sustainable operations.

The authoritative stance of OEM low carbon soft galvanised wires is further reinforced by positive feedback from end-users. Regular testimonials highlight the wires’ ability to withstand high-stress environments while maintaining their functional integrity. Their eco-friendly composition also appeals to environmentally-conscious projects, as the use of less carbon aligns with global sustainability goals. In an era where reducing carbon footprints is imperative, adopting materials that contribute to greener practices enhances a company’s corporate responsibility profile. Experience shared by industry veterans underscores the exceptional performance of these wires in practical applications. Construction managers and engineers recount scenarios where the wires’ flexibility and strength made significant differences in project outcomes, particularly in regions with harsh climatic conditions. The ease of installation and integration into existing systems has made them indispensable tools for various operational needs, streamlining processes that were traditionally labor-intensive and time-consuming. In conclusion, the forward-thinking design and engineering behind OEM low carbon soft galvanised wires position them as the future of sustainable industrial materials. Their multi-industry applicability, combined with a track record of reliability and eco-friendliness, ensures that they remain at the forefront of product innovation. By continuously evolving to meet market demands and environmental expectations, these wires exemplify how advanced technology and conscientious manufacturing can coexist to produce unparalleled outcomes. As businesses navigate the complexities of modern industry requirements, incorporating such advanced materials will undoubtedly provide a competitive edge, enhancing both performance and sustainability.

The authoritative stance of OEM low carbon soft galvanised wires is further reinforced by positive feedback from end-users. Regular testimonials highlight the wires’ ability to withstand high-stress environments while maintaining their functional integrity. Their eco-friendly composition also appeals to environmentally-conscious projects, as the use of less carbon aligns with global sustainability goals. In an era where reducing carbon footprints is imperative, adopting materials that contribute to greener practices enhances a company’s corporate responsibility profile. Experience shared by industry veterans underscores the exceptional performance of these wires in practical applications. Construction managers and engineers recount scenarios where the wires’ flexibility and strength made significant differences in project outcomes, particularly in regions with harsh climatic conditions. The ease of installation and integration into existing systems has made them indispensable tools for various operational needs, streamlining processes that were traditionally labor-intensive and time-consuming. In conclusion, the forward-thinking design and engineering behind OEM low carbon soft galvanised wires position them as the future of sustainable industrial materials. Their multi-industry applicability, combined with a track record of reliability and eco-friendliness, ensures that they remain at the forefront of product innovation. By continuously evolving to meet market demands and environmental expectations, these wires exemplify how advanced technology and conscientious manufacturing can coexist to produce unparalleled outcomes. As businesses navigate the complexities of modern industry requirements, incorporating such advanced materials will undoubtedly provide a competitive edge, enhancing both performance and sustainability.

Latest news

-

Chain Link Fence - Anping County Puersen | Durability&Customization

NewsAug.11,2025

-

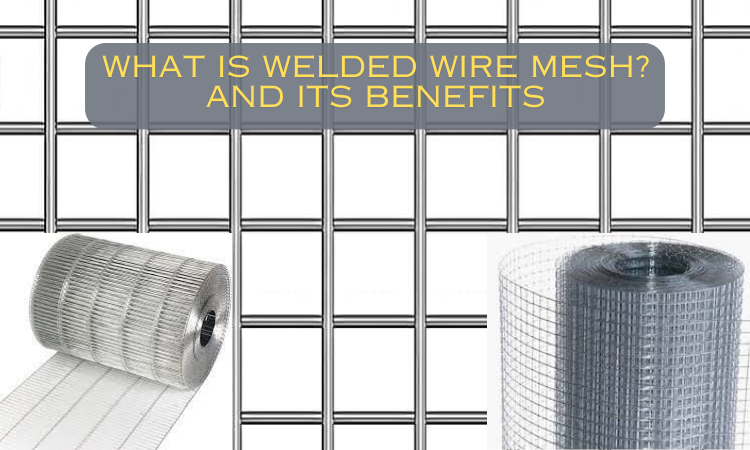

High-Quality Welded Wire Mesh for Industry Factory Direct

NewsAug.11,2025

-

Galvanized Steel Fence Factory | Durable, Versatile, Reliable

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen | Durability, Flexibility, Cost-Effective

NewsAug.11,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable Security, Versatile Application

NewsAug.10,2025