ஜூலை . 23, 2025 11:50 மீண்டும் பட்டியலில்

How PVC Welded Wire Mesh Enhances Industrial Safety Standards

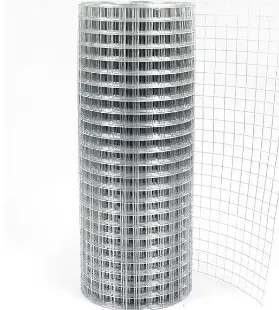

Industrial safety is a cornerstone of modern manufacturing and infrastructure development. Among the many materials and solutions employed to uphold these standards, welded wire mesh has emerged as a versatile and reliable option. Specifically, products like பற்றவைக்கப்பட்ட கம்பி வலை 100x100 மிமீ, பிவிசி பற்றவைக்கப்பட்ட கம்பி வலை, best selling welded wire mesh panel galvanized iron wire, மற்றும் 10 மிமீ ஸ்டீல் பார் வெல்டட் வயர் மெஷ் play pivotal roles in reinforcing safety protocols across industries. This article explores how these specialized mesh products contribute to safer workplaces, durable structures, and compliance with regulatory requirements.

The Role of Welded Wire Mesh 100x100mm in Structural Reinforcement

Welded wire mesh 100x100mm is a grid-like structure made from intersecting steel wires welded at each junction. Its uniform 100mm x 100mm openings provide an optimal balance between strength and visibility, making it ideal for applications requiring both security and airflow. In industrial settings, this mesh is widely used for fencing machinery, creating safety barriers, and reinforcing concrete structures.

The high tensile strength of the steel wires ensures that the mesh can withstand heavy impacts, preventing accidental breaches in hazardous zones. For example, in chemical plants, பற்றவைக்கப்பட்ட கம்பி வலை 100x100 மிமீ acts as a protective shield around volatile equipment, reducing the risk of debris dispersal during malfunctions. Additionally, its corrosion-resistant coatings extend its lifespan, even in humid or chemically aggressive environments.

By integrating பற்றவைக்கப்பட்ட கம்பி வலை 100x100 மிமீ into facility design, industries achieve compliance with safety regulations while maintaining operational efficiency. Its modular design allows for easy installation and customization, ensuring adaptability to diverse industrial layouts.

Advantages of PVC Welded Wire Mesh in Corrosive Environments

பிவிசி பற்றவைக்கப்பட்ட கம்பி வலை combines the structural integrity of steel with the protective benefits of polyvinyl chloride (PVC) coating. This dual-layer construction makes it exceptionally resistant to rust, chemicals, and UV radiation, positioning it as a top choice for industries operating in corrosive or outdoor environments.

In food processing plants, for instance, பிவிசி பற்றவைக்கப்பட்ட கம்பி வலை is used to create hygienic partitions and storage racks. The PVC layer prevents metal-to-food contact, ensuring compliance with sanitation standards. Similarly, in marine facilities, the mesh’s anti-corrosive properties make it suitable for fencing and equipment enclosures exposed to saltwater.

The flexibility of பிவிசி பற்றவைக்கப்பட்ட கம்பி வலை also enhances safety. Unlike rigid barriers, the coated wires can absorb minor impacts without permanent deformation, reducing maintenance costs. Its smooth surface minimizes injury risks during handling, aligning with workplace safety guidelines.

Best Selling Welded Wire Mesh Panel Galvanized Iron Wire: Durability Meets Versatility

The best selling welded wire mesh panel galvanized iron wire is renowned for its durability and wide-ranging applications. Galvanization involves coating steel wires with a layer of zinc, which acts as a sacrificial barrier against rust. These panels are pre-fabricated in standardized sizes, streamlining installation processes in time-sensitive projects.

Construction sites frequently use welded wire mesh panel galvanized iron wire to reinforce concrete slabs and foundations. The mesh distributes weight evenly, preventing cracks and structural failures. In warehousing, these panels serve as secure partitions for inventory storage, protecting workers from falling objects.

The popularity of this product stems from its cost-effectiveness and longevity. Unlike untreated steel, galvanized panels require minimal upkeep, making them a sustainable investment for industries prioritizing safety and budget efficiency.

10mm Steel Bar Welded Wire Mesh: Heavy-Duty Protection for High-Risk Zones

For industries requiring unparalleled strength, 10 மிமீ ஸ்டீல் பார் வெல்டட் வயர் மெஷ் offers a robust solution. Constructed from thick steel bars welded into a grid pattern, this mesh is designed to endure extreme loads and pressures. Its 10mm bar thickness ensures exceptional resistance to bending or breaking, even in high-stress environments.

Mining operations, for example, rely on 10 மிமீ ஸ்டீல் பார் வெல்டட் வயர் மெஷ் to secure tunnels and prevent rockfalls. The mesh’s rigidity also makes it suitable for vehicle barriers in logistics hubs, where collisions are common. Additionally, its open design allows for ventilation and visibility, critical factors in emergency scenarios.

By deploying 10 மிமீ ஸ்டீல் பார் வெல்டட் வயர் மெஷ், industries mitigate risks associated with heavy machinery and dynamic workloads, fostering safer workplaces without compromising productivity.

FAQs About PVC Wமுதியவர் Wகோபம் Mஈஷ் தயாரிப்புகள்

What makes welded wire mesh 100x100mm suitable for outdoor use?

The பற்றவைக்கப்பட்ட கம்பி வலை 100x100 மிமீ is often coated with galvanized or PVC layers, providing resistance to weathering, UV exposure, and corrosion. This ensures long-term durability in outdoor applications like perimeter fencing or construction sites.

How does PVC welded wire mesh enhance hygiene in food facilities?

The PVC coating on பிவிசி பற்றவைக்கப்பட்ட கம்பி வலை creates a non-porous surface that prevents bacterial growth and avoids metal contamination. It is easy to clean and meets strict food safety regulations.

Why is the best selling welded wire mesh panel galvanized iron wire preferred for concrete reinforcement?

Galvanized iron wire panels offer superior tensile strength and rust resistance, ensuring the structural integrity of concrete slabs over time. Their standardized panels simplify installation and reduce labor costs.

Can 10mm Steel Bar Welded Wire Mesh be customized for unique industrial needs?

Yes, manufacturers provide customization options for 10 மிமீ ஸ்டீல் பார் வெல்டட் வயர் மெஷ், including varying dimensions and bar spacing, to meet specific load-bearing or spatial requirements.

Are bulk orders of these பிவிசி பற்றவைக்கப்பட்ட கம்பி வலை products cost-effective?

Absolutely. Bulk purchasing of பற்றவைக்கப்பட்ட கம்பி வலை 100x100 மிமீ, பிவிசி பற்றவைக்கப்பட்ட கம்பி வலை, and other variants reduces per-unit costs, making them ideal for large-scale industrial projects.

From safeguarding workers to reinforcing infrastructure, welded wire mesh products like பற்றவைக்கப்பட்ட கம்பி வலை 100x100 மிமீ, பிவிசி பற்றவைக்கப்பட்ட கம்பி வலை, best selling welded wire mesh panel galvanized iron wire, மற்றும் 10 மிமீ ஸ்டீல் பார் வெல்டட் வயர் மெஷ் are indispensable tools for elevating industrial safety standards. By investing in these solutions, industries not only comply with regulations but also build a foundation for sustainable, accident-free operations. As technology advances, the role of welded mesh in industrial safety will continue to expand, driven by its adaptability, durability, and proven performance.

இதுதான் கடைசிக் கட்டுரை

-

How PVC Welded Wire Mesh Enhances Industrial Safety Standards

செய்திJul.23,2025

-

Hexagonal Wire Mesh Innovations for Coastal Protection Projects

செய்திJul.23,2025

-

Galvanized Wire Fence Maintenance Tips for Harsh Weather Conditions

செய்திJul.23,2025

-

Galvanized Steel Grating Applications in Industrial Flooring Solutions

செய்திJul.23,2025

-

Energy Absorption Capabilities of Twisted Square Bars in Seismic-Resistant Structures

செய்திJul.23,2025

-

Affordable Chain Link Fence Gate Options for Residential Security

செய்திJul.23,2025