Sep . 01, 2025 12:15 Back to list

Welded Wire Mesh for Industry Factory | Structural Strength & Corrosion Resistance

Introduction

Welded wire mesh is a critical material in modern construction, industrial applications, and agricultural systems. Its combination of strength, durability, and adaptability makes it an essential component across various sectors. From reinforcing concrete structures to creating secure fencing solutions, welded wire mesh for industry factory plays a pivotal role in shaping infrastructure and industrial processes. This article provides an in-depth analysis of the product’s features, technical specifications, and real-world applications, supported by authoritative references and industry insights.

Product Overview

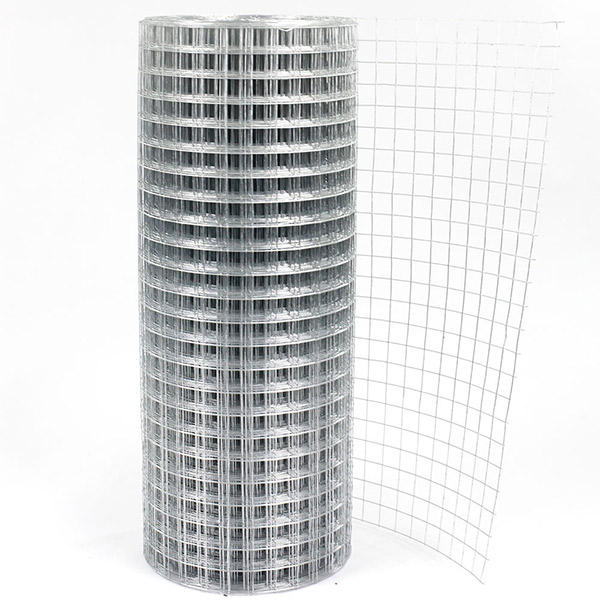

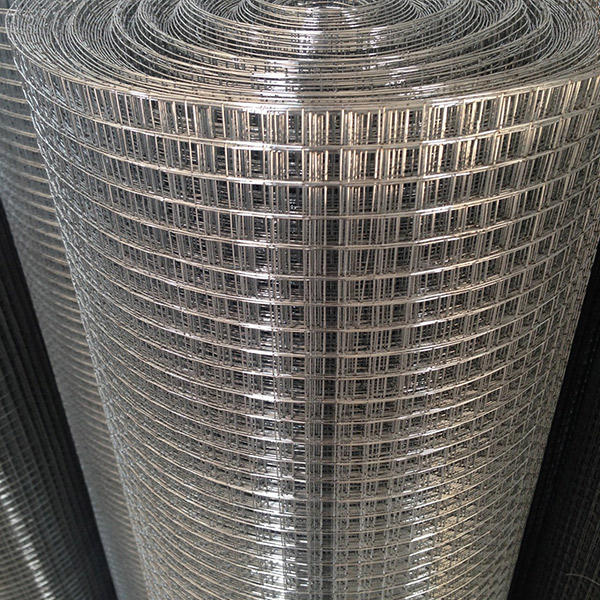

Welded wire mesh is manufactured using low-carbon steel or stainless steel wires, which are welded together at their intersection points to form a grid-like structure. The material undergoes surface treatments such as hot-dip galvanization, electric galvanization, or PVC coating to enhance its resistance to corrosion and environmental wear. These treatments ensure the product’s longevity, making it suitable for both indoor and outdoor applications.

The company background of Anping County Puersen Hardware Wire Mesh Products Co., Ltd. (https://www.building-wiremesh.com/) highlights its commitment to producing high-quality welded wire mesh tailored to diverse industrial needs. As a leading manufacturer, the company offers a wide range of products, including standard, galvanized, and PVC-coated variants, all designed to meet stringent industry standards.

Key Features and Advantages

One of the standout features of welded wire mesh for industry factories is its structural integrity. The welding process ensures that the mesh maintains its shape under heavy loads, making it ideal for applications such as fencing, shelving, and construction reinforcement. Additionally, the material’s ease of installation and cost-effectiveness further enhance its appeal.

Another significant advantage is its versatility. The mesh can be customized to meet specific requirements, including varying wire diameters, opening sizes, and surface treatments. For instance, hot-dip galvanized welded wire mesh provides superior protection against rust, while PVC-coated variants offer enhanced aesthetics and chemical resistance.

Technical Specifications

The following tables detail the standard specifications for different types of welded wire mesh:

Standard Mesh Specifications

| Opening (Inch) | Opening (Metric Unit) | Wire Diameter (BWG) |

|---|---|---|

| 1/4" x 1/4" | 6.4mm x 6.4mm | 22, 23, 24 |

| 3/8" x 3/8" | 10.6mm x 10.6mm | 19, 20, 21, 22 |

| 1/2" x 1/2" | 12.7mm x 12.7mm | 16, 17, 18, 19, 20, 21, 22, 23 |

| 5/8" x 5/8" | 16mm x 16mm | 18, 19, 20, 21 |

| 3/4" x 3/4" | 19.1mm x 19.1mm | 16, 17, 18, 19, 20, 21 |

| 1" x 1/2" | 25.4mm x 12.7mm | 16, 17, 18, 19, 20, 21 |

| 1-1/2" x 1-1/2" | 38mm x 38mm | 14, 15, 16, 17, 18, 19 |

| 1" x 2" | 25.4mm x 50.8mm | 14, 15, 16 |

| 2" x 2" | 50.8mm x 50.8mm | 21, 22, 23, 24 |

Galvanized Welded Wire Mesh Specifications

| Opening (Inch) | Opening (Metric Unit) | Wire Diameter (BWG) |

|---|---|---|

| 2" x 3" | 50mm x 75mm | 2.0mm, 2.5mm, 1.65mm |

| 3" x 3" | 75mm x 75mm | 2.67mm, 2.41mm, 2.11mm, 1.83mm, 1.65mm, 4.0mm |

| 2" x 4" | 50mm x 100mm | 2.11mm, 2.5mm, 3.0mm, 4.0mm |

| 4" x 4" | 100mm x 100mm | 2.0mm, 2.5mm, 3.0mm, 4.0mm |

PVC Coated Welded Wire Mesh Specifications

| Opening (Inch) | Opening (Metric Unit) | Wire Diameter (BWG) |

|---|---|---|

| 1/2" x 1/2" | 12.7mm x 12.7mm | 16, 17, 18, 19, 20, 21 |

| 3/4" x 3/4" | 19mm x 19mm | 16, 17, 18, 19, 20, 21 |

| 1" x 1" | 25.4mm x 25.4mm | 15, 16, 17, 18, 19, 20 |

Common Applications

Welded wire mesh is employed in a wide array of applications, including:

- Fencing and Gates: Welded wire mesh fencing is commonly used for residential, commercial, and industrial properties due to its durability and cost-effectiveness.

- Architectural Uses: The material is used in building facades, infill panels, and decorative elements, offering both structural support and aesthetic appeal.

- Green Building Design: By incorporating welded wire mesh for industry manufacturers, architects can achieve LEED (Leadership in Energy and Environmental Design) credits, contributing to sustainable construction practices.

- Animal Control: Farmers and ranchers utilize welded wire mesh to create secure enclosures for livestock and stray animals.

- Industrial Machinery: Machine guards made from welded wire mesh for industry suppliers protect workers and equipment from hazards.

- Shelving and Partitions: The mesh’s strength makes it ideal for storage solutions and transparent partitions in warehouses and retail spaces.

Industry Relevance and Standards

The use of welded wire mesh for industry factories is supported by rigorous standards to ensure quality and performance. For instance, the National Institute of Standards and Technology (NIST), a U.S. government agency, plays a critical role in developing measurement standards that underpin the reliability of materials like welded wire mesh. According to NIST’s research, precise measurements and material testing are essential for ensuring the safety and efficiency of construction and industrial products (NIST Website).

By adhering to such standards, manufacturers like Anping County Puersen Hardware Wire Mesh Products Co., Ltd. ensure that their products meet the demands of global markets. The company’s commitment to quality is reflected in its diverse product range, which includes options for corrosion resistance, aesthetic finishes, and customized dimensions.

Conclusion

Welded wire mesh is an indispensable material in modern industry, offering a unique blend of strength, versatility, and cost-effectiveness. From construction sites to agricultural fields, its applications are vast and varied. With advancements in surface treatments and manufacturing techniques, the product continues to evolve, meeting the needs of a dynamic market. For businesses seeking reliable solutions, welded wire mesh for industry factories remains a top choice, supported by the expertise of manufacturers like Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

References

NIST. (n.d.). National Institute of Standards and Technology. Retrieved from https://www.nist.gov/

Additional Resources

-

Welded Wire Mesh for Industry Factories - Anping County Puersen | Durability, Versatility

NewsSep.01,2025

-

Welded Wire Mesh-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Corrosion-Resistant Industrial Solutions&Customizable Mesh Applications

NewsSep.01,2025

-

Welded Wire Mesh for Industry - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Structural Reinforcement, Industrial Applications

NewsSep.01,2025

-

Welded Wire Mesh for Industry - Anping County Puersen|Construction, Agriculture, Industrial

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory | Structural Strength & Corrosion Resistance

NewsSep.01,2025