авг . 26, 2025 01:40 Back to list

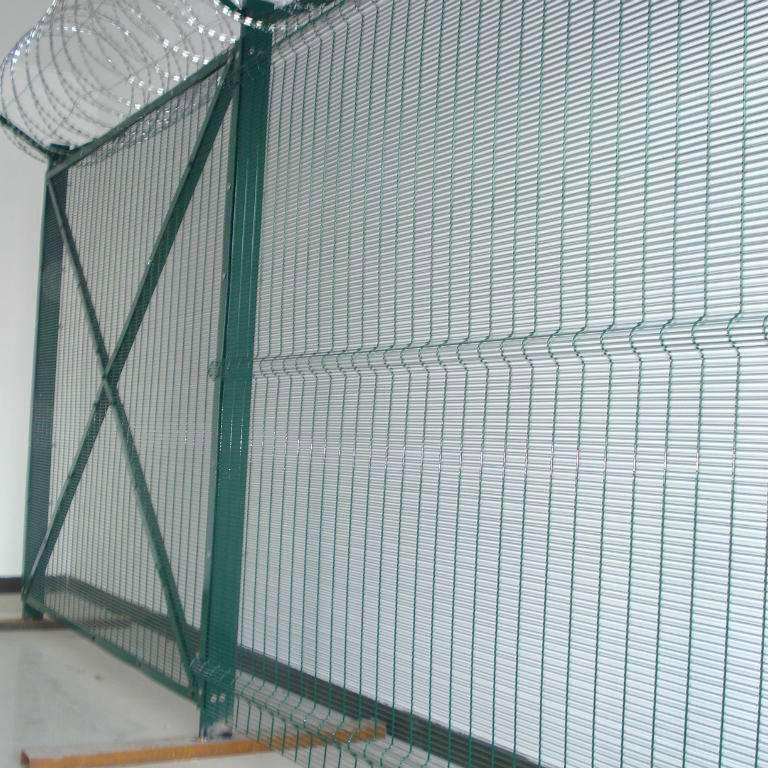

Durable Welded Wire Mesh for Industry Factory - High Quality

Industry Trends in Welded Wire Mesh for Industrial Applications

The demand for welded wire mesh for industry factory applications is experiencing robust growth, driven by an accelerating global industrialization and a heightened focus on robust, cost-effective, and sustainable infrastructure. Key trends influencing this sector include a shift towards automation in manufacturing, increased adoption of advanced materials, and a paramount emphasis on corrosion resistance and extended service life in harsh operating environments. Industries such as petrochemical, mining, construction, and power generation are increasingly specifying high-performance mesh solutions capable of withstanding extreme temperatures, chemical exposure, and significant mechanical stress. The market is also witnessing a surge in demand for customized solutions, moving away from generic products towards specialized designs that precisely meet unique project requirements.

Sustainability is another critical trend, prompting manufacturers to innovate with materials and processes that minimize environmental impact. This includes the development of mesh products with higher recycled content and more energy-efficient production methods. Furthermore, the integration of smart manufacturing principles, such as IoT-enabled quality control and predictive maintenance, is enhancing the reliability and efficiency of welded wire mesh for industry factory production, ensuring consistent quality that meets stringent international standards like ISO 9001 and ASTM A185.

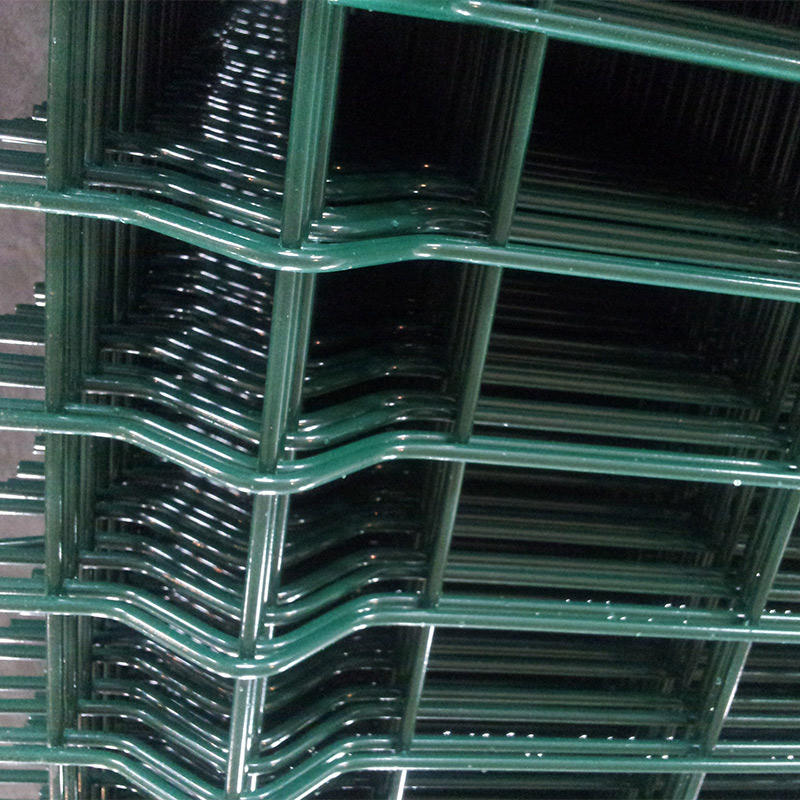

Detailed Manufacturing Process Flow for Industrial Welded Wire Mesh

The production of welded wire mesh for industry factories is a meticulously controlled multi-stage process designed to ensure durability, precision, and performance. Our advanced manufacturing facilities leverage state-of-the-art technology to produce high-quality PVC Coated Welded Wire Panels, adhering strictly to international quality benchmarks.

1. Raw Material Procurement & Inspection

We source premium-grade low carbon steel wire rod, typically conforming to SAE 1008 or equivalent standards. Each batch undergoes rigorous incoming inspection, verifying chemical composition (e.g., carbon, manganese, silicon content), tensile strength, and yield point, ensuring compliance with ASTM A82 or BS EN 10016 specifications. Only materials meeting our stringent quality thresholds are approved for processing.

2. Wire Drawing & Annealing

The steel wire rod is mechanically descaled and then drawn through a series of dies to achieve the desired wire diameter (e.g., 2.0 mm to 6.0 mm). This cold drawing process increases the wire's tensile strength and improves its surface finish. For applications requiring specific ductility, a controlled annealing process may be employed to relieve internal stresses and adjust mechanical properties.

3. Automated Electrowelding

Precisely cut longitudinal and transverse wires are fed into an automated electrowelding machine. This CNC-controlled process ensures every intersection is welded with a strong, consistent electrical resistance weld. The welding parameters (current, time, pressure) are meticulously monitored and adjusted to prevent under-welding or over-welding, which could compromise the mesh integrity. This step ensures uniform mesh aperture and superior structural stability, critical for reliable performance in industrial settings.

4. Surface Treatment (Galvanization)

Post-welding, the mesh panels undergo hot-dip galvanization, conforming to ASTM A123/A123M or BS EN ISO 1461 standards. This involves immersing the mesh in molten zinc, creating a metallurgical bond that provides an exceptionally durable and long-lasting barrier against corrosion and abrasion. The zinc coating thickness is precisely controlled to meet application-specific requirements, typically ranging from 60 to 300 g/m².

5. PVC Coating Application

For PVC Coated Welded Wire Panels, the galvanized mesh is prepared for coating. This involves chemical cleaning and pre-heating. The mesh is then immersed in a fluidized bed of PVC powder or passed through a specialized electrostatic spray booth. The PVC powder fusion-bonds to the heated galvanized surface, forming a thick, uniform, and highly adherent polymer layer. This coating enhances corrosion resistance significantly, provides UV stability, and offers aesthetic benefits. The typical PVC coating thickness is 0.5mm to 1.0mm, tested for adhesion and impact resistance according to relevant ISO standards.

6. Quality Control & Testing

Each finished panel undergoes a comprehensive quality assurance process. This includes visual inspection for defects, dimensional checks (mesh aperture, panel size), wire diameter verification, weld shear strength tests (e.g., in accordance with ASTM A740), and coating thickness/adhesion tests for galvanized and PVC-coated products. Salt spray tests (ASTM B117) are conducted on samples to validate corrosion resistance, ensuring a service life exceeding 15-20 years in typical industrial environments. Our products are certified to ISO 9001:2015 for quality management.

These stringent processes ensure that our welded wire mesh for industry factories consistently delivers superior performance, crucial for demanding applications in petrochemical, metallurgy, water supply & drainage, mining, and agricultural sectors. The PVC coating offers exceptional advantages in energy saving through reduced maintenance needs and unparalleled corrosion resistance, particularly against acidic or alkaline conditions.

Technical Specifications: PVC Coated Welded Wire Panel

Understanding the precise technical parameters is vital for selecting the appropriate welded wire mesh for industry manufacturers. Our PVC Coated Welded Wire Panels are engineered for maximum performance and durability, featuring a robust steel core protected by a resilient polymer coating. Below is a representative specification table outlining key attributes:

| Parameter | Specification Details | Standard / Test Method |

|---|---|---|

| Material (Core Wire) | Low Carbon Steel (SAE 1008 / Q195) | ASTM A82 |

| Wire Diameter (Core) | 2.0 mm - 6.0 mm (Customizable) | ISO 2232 |

| Mesh Aperture | 25x25 mm to 100x100 mm (Customizable) | EN 10223-4 |

| Panel Dimensions | Width: 0.5m - 2.5m; Length: 1.0m - 6.0m (Customizable) | Internal QC / Client Spec |

| Surface Treatment (Base) | Hot-Dip Galvanized | ASTM A123/A123M |

| Zinc Coating Weight | Min. 60 g/m² to 300 g/m² (As per spec) | ISO 1460 |

| Coating Material | Polyvinyl Chloride (PVC) | Internal QC / Supplier Cert |

| PVC Coating Thickness | 0.5 mm - 1.0 mm (Uniform) | ISO 2178 |

| Tensile Strength (Coated Wire) | 450-550 MPa | ASTM A740 |

| Weld Shear Strength | Min. 70% of wire tensile strength | ASTM A740 |

| Corrosion Resistance (Salt Spray) | >1000 hours without significant red rust | ASTM B117 |

| Operating Temperature Range | -30°C to +70°C | Manufacturer Data |

| Expected Service Life | 15-20+ years (depending on environment) | Industry Estimate |

These parameters underscore our commitment to delivering superior industrial mesh products, suitable for the most demanding applications.

Application Scenarios & Technical Advantages

The versatility and robustness of welded wire mesh for industry suppliers make it indispensable across a spectrum of industrial applications. Our PVC Coated Welded Wire Panels offer distinct technical advantages:

Typical Application Scenarios:

- Petrochemical Industry: Used for safety barriers, equipment enclosures, storage racks, and filtration supports in corrosive environments. The PVC coating provides an additional layer of chemical resistance against acids, alkalis, and hydrocarbons.

- Metallurgy & Mining: Employed in mine shaft protection, ore screening, machinery guards, and segregation fences within harsh, abrasive, and often wet conditions. Its high tensile strength and weld integrity ensure structural stability.

- Water Supply & Drainage Systems: Ideal for filter mesh, debris screens, intake screens, and protective covers for pumps and pipes. The exceptional corrosion resistance of the PVC coating makes it suitable for submerged or constantly wet applications, resisting algae and biofilm buildup.

- Construction & Infrastructure: Reinforcement in concrete, security fencing, bridge walkways, and animal enclosures. Its strength-to-weight ratio and ease of installation are significant benefits.

- Agricultural & Aquaculture: Used for livestock pens, crop protection, and fish farm enclosures. The smooth PVC coating is safe for animals and resists degradation from organic matter and UV exposure.

- General Industrial Manufacturing: Machine guards, shelving, partitions, and component drying racks where protection, ventilation, and a clean aesthetic are required.

Technical Advantages:

- Superior Corrosion Resistance: The dual protection of hot-dip galvanization and a thick PVC coating offers unparalleled resistance against rust, chemical attack, and environmental degradation, significantly extending product lifespan compared to uncoated or solely galvanized mesh. This translates to reduced maintenance costs and greater operational uptime.

- Enhanced Durability & Structural Integrity: Precision electrowelding ensures high weld shear strength, preventing wire separation under stress. The base steel wire's high tensile strength provides inherent robustness, capable of bearing substantial loads and resisting impact.

- Reduced Maintenance & Energy Saving: The low-maintenance nature of PVC-coated mesh means fewer repairs, replacements, and repainting. In terms of energy saving, its longevity and resistance to degradation contribute to a lower total cost of ownership (TCO) and reduced resource consumption over its lifecycle.

- UV and Weather Resistance: Specialized PVC formulations include UV stabilizers, ensuring the coating resists fading, cracking, and chalking even under prolonged exposure to sunlight and harsh weather conditions.

- Safety and Aesthetic Appeal: The smooth, non-abrasive PVC coating eliminates sharp edges, enhancing safety for personnel and animals. It also provides a clean, professional appearance available in various colors to blend with specific facility aesthetics or branding.

- Chemical Inertness: PVC is largely inert to a wide range of chemicals, making these panels ideal for environments where exposure to acids, alkalis, salts, and oils is common.

Vendor Comparison & Customized Solutions

Choosing the right supplier for welded wire mesh for industry factories is a critical decision that impacts project timelines, budget, and long-term performance. While many suppliers exist, differentiation often lies in manufacturing capabilities, quality assurance, and ability to provide tailored solutions.

Key Considerations for Vendor Comparison:

| Feature | Standard Vendor Offerings | Our Advanced Offerings |

|---|---|---|

| Raw Material Sourcing | Varied quality, sometimes uncertified. | Premium, certified low carbon steel (SAE 1008), traceable. |

| Welding Technology | Basic resistance welding, potential inconsistencies. | Automated CNC electrowelding, consistent weld strength per ASTM A740. |

| Corrosion Protection | Pre-galvanized or light hot-dip galvanized. | Heavy hot-dip galvanized (ASTM A123) + uniform PVC coating. |

| Coating Quality | Thin, inconsistent PVC, prone to peeling/fading. | 0.5-1.0mm thick, UV-stabilized, fusion-bonded PVC, tested for adhesion. |

| Customization Options | Limited standard sizes and mesh apertures. | Extensive customization: wire gauge, mesh size, panel dimensions, color. |

| Certifications | Basic or no relevant certifications. | ISO 9001:2015, CE compliance, adherence to ASTM/EN standards. |

| Customer Support | Reactive, limited technical assistance. | Proactive technical consulting, dedicated project management. |

Customized Solutions for Complex Industrial Needs:

We understand that off-the-shelf solutions rarely fit the precise requirements of complex industrial projects. Our expertise in welded wire mesh for industry factories extends to providing highly tailored solutions:

- Specific Mesh Configurations: We can produce mesh panels with varying wire diameters, mesh apertures, and panel sizes to meet exact design specifications for filtration, guarding, or structural reinforcement.

- Specialized Coatings: Beyond standard PVC, we offer coatings optimized for extreme chemical resistance, high-temperature applications (e.g., specific polymer blends), or enhanced anti-microbial properties for sensitive environments.

- Integrated Components: Fabrication services include bending, cutting, notching, and incorporating mounting brackets or framing elements directly into the mesh panels, streamlining installation processes for our clients.

- Engineering Support: Our team of engineers collaborates with clients from conception to deployment, offering design optimization, material selection advice, and structural analysis to ensure the final product meets all performance criteria.

Application Case Studies & Customer Feedback

Our commitment to quality and custom engineering has resulted in successful deployments of welded wire mesh for industry factory applications across diverse and challenging environments. Below are illustrative case studies and examples of positive feedback:

Case Study 1: Chemical Plant Safety Enclosures

A major petrochemical client required robust safety enclosures for critical processing units exposed to corrosive fumes (e.g., hydrochloric acid, sulfur dioxide). Traditional galvanized mesh required frequent maintenance due to accelerated corrosion. We supplied custom-fabricated PVC Coated Welded Wire Panels with enhanced PVC thickness (0.8mm) and specific UV stabilizers. The installation dramatically reduced maintenance cycles by over 70% and eliminated premature degradation, providing a safer, more durable barrier. The client reported, "The PVC-coated mesh has withstood conditions far better than anything we've used before. It's a significant improvement in operational safety and cost-efficiency."

Case Study 2: Municipal Water Treatment Filtration

For a large-scale municipal water treatment plant, coarse filtration screens were needed to prevent debris from entering sensitive pumping stations. The screens needed to be highly resistant to continuous water immersion, biological growth, and occasional chemical shock treatments. Our solution involved large format (2.0m x 4.0m) PVC Coated Welded Wire Panels with a precise 50x50mm mesh aperture, engineered for optimal flow rates and debris capture. The panels exhibited excellent resistance to fouling and corrosion over two years, outperforming the previously used stainless steel options in terms of cost-effectiveness and durability in their specific aquatic environment.

Customer Feedback Highlights:

- "The lead time was precise, and the product quality for our mine shaft safety barriers was exceptional. Weld integrity was perfect, crucial for our demanding environment." - Mining Operations Manager, South America.

- "We've been using their PVC coated mesh for several years in our food processing plant for equipment guards. The cleanability and anti-corrosion properties are exactly what we need for HACCP compliance." - QA Director, Food & Beverage Sector.

- "Their technical team was instrumental in designing the custom mesh panels for our new power plant's perimeter fencing. The detailed engineering support saved us significant time and resources." - Project Engineer, Energy Sector.

Trustworthiness & Support: FAQ, Lead Time, Warranty

Frequently Asked Questions (FAQ):

- Q: What is the primary advantage of PVC Coated Welded Wire Mesh over standard galvanized mesh?

- A: The PVC coating provides an additional, highly effective barrier against corrosion, chemical exposure, and UV radiation, significantly extending the service life and reducing maintenance in harsh environments. It also offers aesthetic benefits and a smooth, safe surface.

- Q: Can your mesh withstand extreme temperatures?

- A: Our standard PVC-coated mesh is rated for continuous operating temperatures from -30°C to +70°C. For applications requiring higher temperature resistance, we can discuss specialized polymer coatings or alternative material constructions.

- Q: How do you ensure the quality of the welds?

- A: We utilize advanced automated electrowelding machines with precise parameter controls. Post-production, weld shear strength tests are routinely performed in accordance with ASTM A740 to verify that each weld exceeds minimum strength requirements, ensuring the structural integrity of every panel.

- Q: What is the minimum order quantity (MOQ) for customized panels?

- A: MOQ for customized panels varies depending on the complexity of the specification and raw material availability. Please contact our sales team with your specific requirements for a detailed quotation and MOQ information.

Lead Time & Fulfillment:

Our standard lead time for PVC Coated Welded Wire Panels typically ranges from 4 to 6 weeks, depending on order volume and specific customization requirements. Expedited options may be available upon request. We maintain efficient production schedules and robust logistics partnerships to ensure timely delivery to industrial facilities worldwide. Detailed production schedules and estimated delivery dates are provided upon order confirmation.

Warranty Commitments:

We stand behind the quality and durability of our products. Our PVC Coated Welded Wire Panels come with a 5-year limited warranty against manufacturing defects and premature coating failure under normal operating conditions. This warranty reflects our confidence in our manufacturing processes and the high-grade materials used. Specific warranty terms and conditions are available upon request.

Customer Support & After-Sales Service:

Our commitment to our clients extends far beyond the point of sale. We provide comprehensive after-sales support, including technical assistance for installation, maintenance guidelines, and troubleshooting. Our dedicated customer service team is available via phone and email during business hours, with emergency technical support available 24/7 for critical industrial operations. We are focused on building long-term partnerships through reliable products and exceptional service.

References:

- American Society for Testing and Materials (ASTM) International. (Various Standards).

- International Organization for Standardization (ISO). (ISO 9001:2015, ISO 1461, etc.).

- British Standards Institution (BSI). (BS EN 10016, BS EN ISO 1461, etc.).

- The Galvanizing Association. (Technical Publications on Hot Dip Galvanizing).

- "Handbook of Steel Construction" by American Institute of Steel Construction (AISC).

This is the last article

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025