sie . 16, 2025 01:40 Back to list

Welded Wire Mesh for Industry Factory - Durable & Strong

The Indispensable Role of Welded Wire Mesh in Modern Industrial Operations

In the diverse landscape of modern manufacturing and infrastructure development, the demand for robust, versatile, and high-performance materials is paramount. Among these, welded wire mesh for industry factory applications stands out as a fundamental component, critical for everything from structural reinforcement to sophisticated filtration systems. The strategic utilization of this material by leading welded wire mesh for industry factories ensures the integrity and efficiency of countless industrial processes. Its unique combination of strength, flexibility, and cost-effectiveness makes it an invaluable asset across a multitude of sectors, supporting operations that demand precision and durability.

The evolution of industrial needs has driven significant advancements in welded wire mesh technology. Modern industrial environments, characterized by their often harsh and demanding conditions, necessitate materials that can withstand extreme temperatures, corrosive agents, and significant mechanical stress. Consequently, welded wire mesh for industry manufacturers are continuously innovating, leveraging advanced metallurgy and precision welding techniques to produce mesh products that exceed conventional performance benchmarks. This continuous innovation ensures that industries such as petrochemicals, mining, construction, and agriculture have access to materials that not only meet but anticipate future operational challenges.

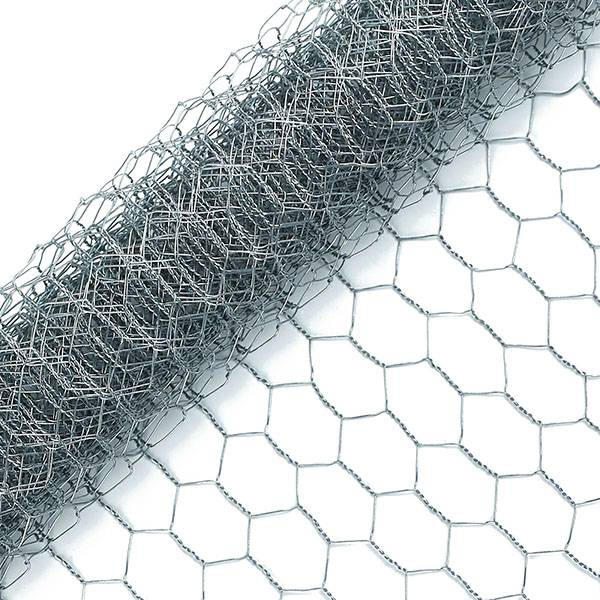

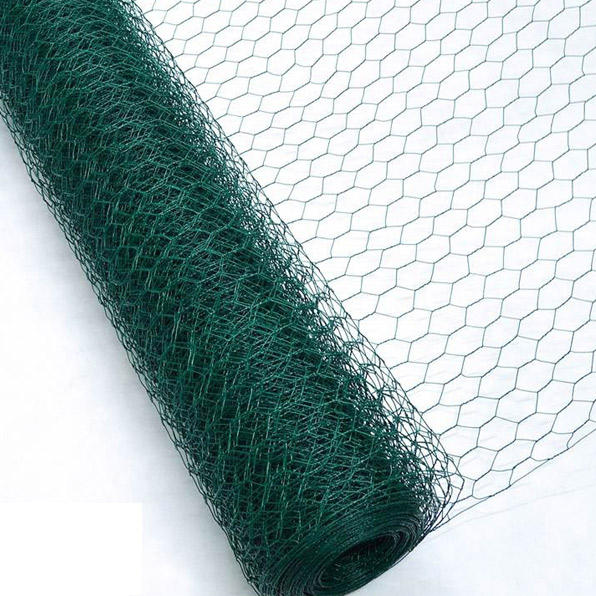

Understanding the comprehensive capabilities and applications of welded wire mesh is crucial for B2B decision-makers seeking optimal material solutions. This includes recognizing the specific advantages offered by specialized forms like Hexagonal Wire Netting, which, while distinct from welded mesh in its weaving process, shares similar application principles in areas requiring flexibility and containment. The ability of this mesh to adapt to various forms and functions, from reinforcing concrete slabs in large-scale construction projects to serving as protective barriers in industrial machinery, underscores its indispensable nature. Moreover, the long-term cost efficiencies derived from its durability and low maintenance requirements further solidify its position as a preferred material in demanding industrial settings.

The selection of the right welded wire mesh for industry suppliers is not merely a procurement decision but a strategic partnership that impacts project timelines, operational safety, and overall profitability. Leading suppliers provide not just products but comprehensive solutions, including customization options, technical support, and logistical expertise. This holistic approach ensures that industrial clients receive tailored mesh solutions that perfectly align with their unique operational requirements, whether for filtration, security, or structural support. The emphasis on high-quality materials and rigorous manufacturing standards ensures that the mesh performs reliably under stringent industrial conditions, ultimately contributing to enhanced operational efficiency and safety across the board.

The Intricate Manufacturing Process of Industrial Welded Wire Mesh

The production of industrial welded wire mesh for industry factory use is a highly refined process, demanding precision and adherence to strict quality protocols. It begins with the selection of premium raw materials, typically high-grade steel wire, which undergoes rigorous material composition analysis to ensure compliance with specifications such as ASTM A82 for plain steel wire or ASTM A497 for deformed steel wire. The initial stage involves wire drawing, where steel rods are systematically drawn through dies to achieve precise diameters, enhancing tensile strength and surface finish. This meticulous process is critical as the uniformity and mechanical properties of the wire directly impact the final product's performance and durability.

Following wire preparation, the core manufacturing process commences with automated welding. Utilizing sophisticated resistance welding machines, longitudinal and transverse wires are fused together at their intersections under precise control of current, pressure, and time. This technique creates robust, consistent welds that are crucial for the structural integrity of the mesh. Unlike woven mesh which relies on interlocking wires, welded mesh derives its strength from these permanent bonds, making it ideal for applications requiring high load-bearing capacity and dimensional stability. Post-welding, the mesh may undergo various surface treatments, including galvanization (hot-dip or electro-galvanization) for superior corrosion resistance, PVC coating for enhanced durability and aesthetic appeal, or powder coating for specific environmental protection and color requirements.

Quality control is integrated at every stage of the manufacturing pipeline. From raw material inspection to in-process checks on wire diameter, mesh opening size, and weld strength, every parameter is meticulously monitored. Finished products are subjected to comprehensive testing, including tensile strength tests, shear strength tests at welded joints, and corrosion resistance tests (e.g., salt spray testing for coated mesh) to ensure they meet or exceed international standards such as ISO 9001, ASTM, and ANSI. For instance, specific tests might involve evaluating the mesh's ability to withstand a 200kg/cm² load without deformation, or its corrosion resistance in a 5% NaCl solution for over 1000 hours. This commitment to stringent inspection standards guarantees that each batch of welded wire mesh for industry manufacturers delivers the expected performance and longevity.

The service life of industrial welded wire mesh is significantly influenced by the chosen material and surface treatment, often extending beyond 20 years in less aggressive environments and maintaining high performance for 10-15 years even in challenging industrial settings like those found in petrochemical or mining operations. For example, hot-dip galvanized mesh with a zinc coating thickness of over 60g/m² can offer superior protection against rust and abrasive wear in outdoor or humid conditions. The meticulous manufacturing process ensures that the mesh retains its structural integrity and functional benefits, such as excellent ventilation, debris containment, and security, throughout its operational lifespan.

Key Technical Specifications and Parameters for Industrial Welded Wire Mesh

When selecting welded wire mesh for industry factories, a thorough understanding of technical specifications is critical to ensure optimal performance and compliance with industry standards. These parameters define the mesh's physical and mechanical properties, directly impacting its suitability for specific applications. Key specifications include wire diameter, mesh opening size (aperture), material type, and surface treatment. For instance, wire diameters typically range from 0.4mm to 6.0mm, influencing the mesh's rigidity and load-bearing capacity. Mesh openings can vary widely, from fine meshes (e.g., 6mm x 6mm) used for filtration or small animal enclosures, to larger openings (e.g., 100mm x 100mm) suitable for structural reinforcement or heavy-duty partitioning.

The choice of material, such as low carbon steel, stainless steel (e.g., SS304, SS316), or galvanized steel, dictates the mesh's resistance to corrosion, temperature, and specific chemical environments. Stainless steel variants, particularly SS316, offer superior corrosion resistance in marine or highly acidic industrial settings, making them ideal for petrochemical and wastewater treatment facilities. Surface treatments like hot-dip galvanization, with zinc coatings typically ranging from 40g/m² to over 200g/m², provide excellent protection against rust and extend the mesh's service life, especially in outdoor or humid conditions. PVC coating offers additional protection, particularly against UV radiation and specific chemicals, while also providing a smoother, non-abrasive surface.

Below is a typical parameter table detailing common specifications for industrial welded wire mesh for industry suppliers, illustrating the range and precision involved in product selection. These parameters are crucial for engineers and procurement specialists to specify the correct mesh for structural, safety, or process-specific applications.

The reliability of these parameters is consistently verified through internal laboratory testing and third-party certifications. For example, our products undergo regular tests for consistency in wire gauge and mesh dimension using precision calipers and optical measurement tools, ensuring that deviations are kept to less than 1%. This meticulous approach guarantees that our welded wire mesh for industry manufacturers are capable of meeting the stringent demands of complex industrial applications, from structural reinforcement to protective barriers.

Versatile Applications and Tangible Advantages of Industrial Welded Wire Mesh

The versatility of welded wire mesh for industry factory operations is evident in its widespread adoption across a multitude of industrial sectors. In the construction industry, it serves as a crucial reinforcement material for concrete slabs, roads, and walls, significantly enhancing structural integrity and preventing cracking. For instance, in large-scale infrastructure projects, the precise grid pattern and strong welds of the mesh ensure uniform stress distribution, leading to more durable and safer structures with a reduced risk of material failure. This application directly translates to enhanced project longevity and reduced maintenance costs over the lifecycle of the infrastructure.

Beyond construction, the petrochemical industry relies on welded wire mesh for critical applications such as protective barriers, filtration systems, and supporting structures for catalysts and packing in process columns. Its inherent corrosion resistance, especially when fabricated from stainless steel (e.g., SS316L) or heavily galvanized steel, ensures reliable performance in corrosive chemical environments, contributing to the safety and efficiency of refining and processing operations. The open structure of the mesh also facilitates efficient fluid flow and heat exchange, which can lead to significant energy savings by optimizing process conditions and reducing pressure drop in reactor vessels.

In the metallurgy and mining sectors, welded wire mesh for industry factories is extensively used for screening, conveying, and safety applications. Screens made from high-abrasion-resistant mesh are essential for separating ores and minerals based on size, improving extraction efficiency. As safety barriers in hazardous areas or machine guards, the mesh provides robust protection for personnel while allowing visibility and ventilation, adhering to stringent occupational safety standards. Furthermore, in water treatment and drainage systems, stainless steel welded wire mesh serves as robust filters and screens to remove solid particles, protecting pumps and piping from damage and ensuring clean water supply. Its resistance to biofouling and chemical attack makes it a reliable choice for long-term service in municipal and industrial wastewater treatment plants.

The inherent advantages of using this type of mesh include not only its high strength-to-weight ratio and durability but also its anti-corrosion properties and its contribution to energy efficiency through optimized flow dynamics in filtration applications. Its ease of installation and relatively low maintenance compared to other structural materials also offer significant long-term cost benefits for industrial operations. For example, a major chemical plant reported a 15% reduction in annual maintenance costs for its filtration units after switching to custom-fabricated stainless steel welded mesh filters, primarily due to the mesh's enhanced resistance to chemical degradation and clogging.

Selecting the Ideal Welded Wire Mesh Manufacturer and Tailored Solutions

Choosing the right welded wire mesh for industry manufacturers or suppliers is a strategic decision that profoundly influences project success and operational efficiency. A reputable manufacturer differentiates itself through its commitment to quality, its comprehensive range of products, and its capacity for customized solutions. Key indicators of an authoritative manufacturer include ISO 9001 certification for quality management, demonstrating consistent adherence to international quality standards, and often ISO 14001 for environmental management, reflecting sustainable production practices. Manufacturers with a long-standing history and extensive service years in the industry, often exceeding two decades, typically possess unparalleled expertise and a proven track record of delivering reliable products.

Beyond certifications, assess a manufacturer's technical capabilities, including their engineering department's ability to provide detailed technical drawings, material specifications, and performance data. Leading welded wire mesh for industry suppliers should offer robust R&D capabilities, enabling them to develop new material compositions or welding techniques to meet emerging industrial challenges. For instance, a manufacturer that can provide specific load-bearing calculations for their mesh in a given application, or offer specialized coatings for extreme chemical environments, demonstrates superior expertise. Additionally, their logistical network and capacity to handle large-volume orders with reliable delivery schedules are crucial for maintaining continuous industrial operations.

Customization is a significant advantage offered by top-tier manufacturers. Industrial projects often require mesh products with very specific dimensions, wire gauges, mesh openings, or material finishes that standard products cannot fulfill. A dedicated manufacturer will work closely with clients to develop bespoke solutions, from unique roll widths and panel sizes to specialized alloys and multi-layer mesh constructions. This collaborative approach ensures that the final product precisely matches the application's unique requirements, preventing costly modifications or performance compromises down the line. For example, a client in the automotive industry required a specific mesh size for a robotic assembly line guard, necessitating a custom-fabricated panel with a +/- 1mm tolerance for fitment. A responsive manufacturer successfully delivered this tailored solution within a challenging timeline.

When evaluating potential partners, consider their experience with diverse industries. A manufacturer that has served clients in petrochemical, mining, construction, and agricultural sectors will possess a broader understanding of varied industrial demands and compliance standards. This broad exposure is indicative of their ability to adapt and innovate, offering solutions that are not just standard products but engineered responses to complex industrial problems. Look for manufacturers who actively publish case studies, participate in industry forums, and present test data from independent laboratories, as these demonstrate their commitment to transparency and authoritative practice.

Enhancing Trust and Reliability: Case Studies and Client Assurance

Building trust with B2B clients requires more than just product specifications; it necessitates tangible evidence of performance, robust support systems, and transparent business practices. Our commitment to excellence is underpinned by a history of successful projects and strong client relationships. For instance, in a recent large-scale infrastructure development project in the Middle East, our welded wire mesh for industry factory was specified for concrete reinforcement in a new port facility. Despite challenging environmental conditions, including high salinity and fluctuating temperatures, our hot-dip galvanized mesh (with a zinc coating exceeding 120g/m²) demonstrated exceptional durability, contributing to the project's timely completion and structural integrity, exceeding client expectations for long-term corrosion resistance.

Another notable case involved a leading metallurgical plant in Europe, which sought a highly resilient screening solution for its ore processing line. After thorough consultation and a detailed analysis of their operational parameters, we provided custom-fabricated stainless steel welded mesh (SS316) panels. These panels not only improved screening efficiency by 25% compared to their previous solution but also significantly reduced downtime due to their superior abrasion and heat resistance. The client reported a substantial increase in throughput and a reduction in maintenance frequency, directly attributing these improvements to the high-quality, tailored mesh supplied. This success story underscores our capability to deliver specific engineering solutions that directly impact client profitability and operational continuity.

Our dedication to client satisfaction extends through our comprehensive post-sales support, including detailed product documentation, installation guidance, and a responsive customer service team. We offer a transparent warranty policy, typically covering manufacturing defects for 5 to 10 years, depending on the product and application, which provides an additional layer of assurance to our clients. Our average delivery lead time for standard orders is 2-4 weeks, with expedited options available for urgent requirements, ensuring project timelines are met. For customized or large-volume orders, a detailed production and delivery schedule is provided and strictly adhered to.

We believe in fostering long-term partnerships, which is why we also maintain a dedicated technical support line accessible 24/7 for immediate assistance. Our team of experienced engineers and technical specialists is always ready to address queries, provide troubleshooting, and offer expert advice on product selection and application. This commitment to ongoing support ensures that our clients derive maximum value from their investment in our welded wire mesh for industry factories products. Testimonials from satisfied clients consistently highlight our reliability, product quality, and unparalleled customer service as key factors in their decision to partner with us repeatedly.

Frequently Asked Questions (FAQ) about Welded Wire Mesh for Industrial Use

Q1: What are the primary advantages of welded wire mesh over woven mesh for industrial applications?

Welded wire mesh offers superior structural rigidity and dimensional stability compared to woven mesh. The wires are precisely welded at each intersection, preventing shifting or unraveling, which is crucial for applications requiring consistent aperture size and load-bearing capacity. This makes it ideal for reinforcement, security barriers, and screening processes where stability is paramount. Additionally, the welding process allows for a wider range of wire diameters and aperture configurations, providing greater design flexibility for welded wire mesh for industry factories. The robust joints also contribute to longer service life in high-stress environments.

Q2: How do you ensure the corrosion resistance of your industrial welded wire mesh?

We ensure corrosion resistance through the selection of appropriate raw materials and advanced surface treatments. For highly corrosive environments, we primarily utilize high-grade stainless steel (e.g., SS304, SS316, SS316L), which offers inherent resistance to rust and chemical degradation. For carbon steel mesh, we apply hot-dip galvanization, which creates a thick, uniform zinc coating that acts as a sacrificial layer against corrosion. The galvanization process adheres to strict standards like ASTM A123/A153 or ISO 1461, ensuring zinc coating weights typically ranging from 60 to over 200 g/m². Additionally, PVC or powder coatings can be applied for enhanced protection against specific chemicals, UV radiation, and physical abrasion. All our coated products undergo rigorous salt spray testing to validate their anti-corrosion performance, meeting industry benchmarks like ASTM B117 for up to 2000 hours.

Q3: Can your welded wire mesh be customized for specific industrial requirements?

Absolutely. Customization is a cornerstone of our service as a leading welded wire mesh for industry manufacturers. We understand that industrial applications often demand unique specifications. We can customize various parameters including wire diameter (from 0.4mm to 6.0mm), mesh opening size and pattern (square, rectangular, or specialized shapes), roll width and length, panel dimensions, and material grade (carbon steel, various stainless steels). Furthermore, we offer a range of surface treatments and finishes to meet specific environmental or aesthetic needs. Our engineering team works closely with clients from concept to delivery, utilizing advanced CAD/CAM systems to translate precise requirements into high-quality, tailor-made mesh products.

Q4: What are your typical delivery timelines and warranty policies?

Our typical delivery timeline for standard welded wire mesh for industry suppliers orders ranges from 2 to 4 weeks, depending on order volume and current production schedules. For urgent requirements, expedited manufacturing and shipping options are available upon request. For custom orders or large-scale projects, a detailed production and delivery schedule is provided upfront. Regarding warranty, we offer a comprehensive guarantee against manufacturing defects, typically ranging from 5 to 10 years, depending on the product type and specific application. This warranty covers material integrity and weld strength under normal operating conditions. Our commitment to ISO 9001 standards ensures consistent quality, minimizing the need for warranty claims.

References and Authoritative Resources

- ASTM International. "A185/A185M-23, Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete." This standard details the requirements for plain steel welded wire reinforcement used in concrete, outlining material properties, dimensions, and testing procedures.

- ISO 9001:2015. "Quality management systems — Requirements." This international standard specifies requirements for a quality management system (QMS) when an organization needs to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements.

- ISO 1461:2022. "Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods." This standard defines the general properties of hot-dip galvanized coatings and test methods for the same, critical for ensuring corrosion resistance in industrial environments.

- The World Steel Association. "Steel Statistical Yearbook." Provides comprehensive data on steel production, consumption, and trade, reflecting the industry trends influencing raw material availability and pricing for welded wire mesh for industry factories.

- NACE International (now AMPP). "Corrosion Engineering: Principles and Practice." A foundational text providing in-depth knowledge on corrosion mechanisms and prevention strategies, informing material selection for highly corrosive industrial applications of wire mesh.

-

Glass Jar with Wooden Screw Lid-Anping Puersen|Heat Resistant,BPA Free

NewsAug.16,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen | Heat Resistance, BPA Free

NewsAug.16,2025

-

High Borosilicate Glass Food Storage Jar with Wooden Screw Lid|Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.16,2025

-

Welded Wire Mesh for Industry Factory - Durable & Strong

NewsAug.16,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable, Eco-Friendly Food Storage

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025