Nov . 24, 2024 02:15 Back to list

wire diameter 6mm welded wire mesh factory

Understanding 6mm Diameter Welded Wire Mesh Applications and Benefits from a Factory Perspective

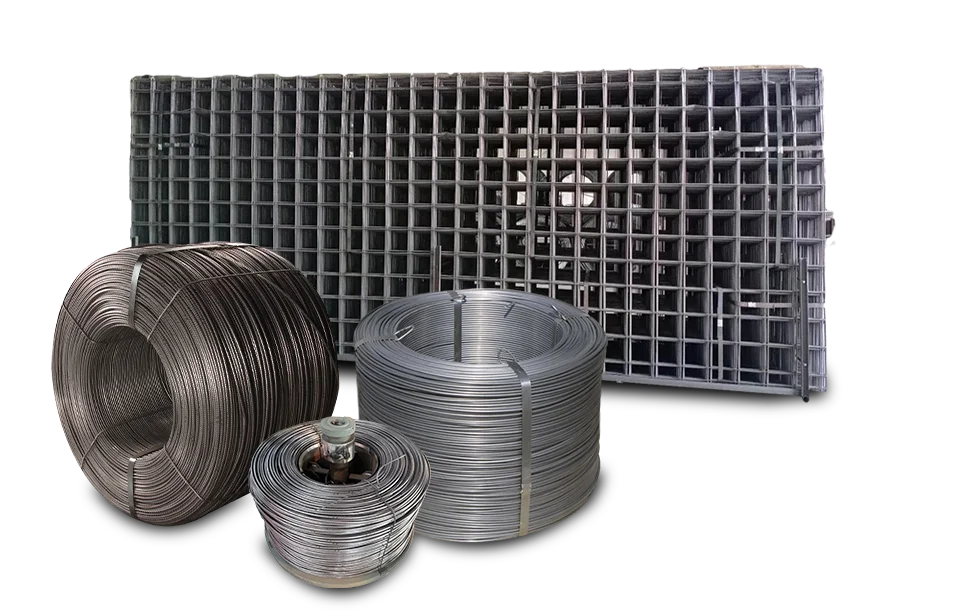

Welded wire mesh is an essential component in various construction and industrial applications, providing both strength and versatility. Among the various specifications available, the 6mm wire diameter welded wire mesh is particularly noteworthy due to its robust characteristics and wide range of uses. This article delves into the manufacturing process, applications, and benefits of 6mm diameter welded wire mesh from the perspective of a factory specializing in this product.

Manufacturing Process

The production of 6mm diameter welded wire mesh begins with the careful selection of raw materials. High-quality steel wire is essential, as it directly influences the durability and strength of the finished product. The wire is first drawn to the desired diameter, in this case, 6mm, through a series of die tools that reduce its thickness while maintaining its tensile strength. The next step involves the formation of a mesh grid, where the wires are arranged in a perpendicular configuration.

Once the grid is established, a welding process is employed. This involves applying heat and pressure at the junctions, where the horizontal and vertical wires intersect. Automated welding machines ensure consistency and precision, producing a sturdy mesh product that can withstand significant stresses. Finally, the welded wire mesh is treated to prevent corrosion, which may include galvanization or the application of plastic coatings, enhancing its longevity and suitability for outdoor applications.

Applications of 6mm Welded Wire Mesh

The versatility of 6mm welded wire mesh makes it suitable for a plethora of applications across various industries. One prominent use is in construction, where it is employed for reinforcing concrete structures. The mesh provides added tensile strength, aiding in the stability of pavements, walls, and ceilings. This significantly reduces the risk of cracking due to shrinkage or settlement.

In agriculture, 6mm welded wire mesh is widely used for fencing purposes. It serves as an effective barrier against livestock and wildlife while allowing for visibility and air circulation. Additionally, it is utilized in the construction of cages and pens, providing secure environments for animals.

wire diameter 6mm welded wire mesh factory

Manufacturers also find applications for this type of mesh in the production of security fencing. Its sturdy nature deters trespassers, providing a reliable layer of protection for residential and commercial properties. The mesh can be coated in various materials, enhancing not only its aesthetic appeal but also its protective qualities against the elements.

Benefits of 6mm Welded Wire Mesh

One of the most significant advantages of 6mm welded wire mesh is its strength-to-weight ratio. The robust design can endure considerable stress while remaining relatively lightweight, making it easy to handle and install. The uniform grid pattern also ensures even distribution of forces, preventing localized failures.

Moreover, welded wire mesh provides excellent visibility and airflow. Unlike solid walls or barriers, the mesh allows light to penetrate and air to circulate, which is crucial in agricultural settings where crops require sunlight.

Another benefit lies in its cost-effectiveness. Once in place, 6mm welded wire mesh requires little maintenance, translating to long-term savings. Its durability means fewer replacements, making it a smart investment for both industrial and domestic applications.

Conclusion

In summary, 6mm diameter welded wire mesh represents a pinnacle of engineering excellence within the construction and agricultural domains. From its manufacturing process to its diverse applications and numerous benefits, it exemplifies quality and versatility. As factories continue to innovate in the production of this essential product, its importance in enhancing structural integrity, security, and efficiency across various sectors cannot be overstated. With ongoing advancements in material science and production techniques, the future of welded wire mesh looks promising, ensuring that it remains a staple in construction and industry for years to come.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025