Nov . 04, 2024 18:13 Back to list

Affordable Welded Wire Mesh Panels for Concrete Applications and Construction Needs

Understanding Wholesale Welded Wire Mesh Panels for Concrete Applications

Welded wire mesh panels have become a staple in construction for a variety of applications, particularly in concrete reinforcement. The demand for these products has surged, prompting numerous manufacturers to offer wholesale options to builders, contractors, and suppliers seeking cost-effective and durable solutions.

What is Welded Wire Mesh?

Welded wire mesh consists of a grid of wires that are welded together at intersections, creating a strong and stable framework. This grid can come in various sizes, shapes, and wire gauges, depending on the intended use. For concrete applications, the mesh panels are used to provide additional strength and stability to poured concrete structures, such as slabs, walls, and foundations.

Benefits of Using Welded Wire Mesh Panels

1. Strength and Durability One of the standout features of welded wire mesh is its ability to significantly enhance the tensile strength of concrete structures. The mesh helps distribute loads evenly, reducing the risk of cracking and ensuring longevity.

2. Cost-Effectiveness Buying welded wire mesh panels wholesale can lead to substantial savings for construction projects. Bulk purchasing reduces costs per unit, allowing contractors to budget more effectively for their projects.

3. Ease of Installation Welded wire mesh panels are easy to handle and install. They come pre-cut and can be placed quickly within concrete forms, saving time during the construction process. This efficiency is vital for meeting project deadlines and keeping labor costs down.

4. Versatility These panels can be used in a wide variety of concrete applications. Whether it’s residential, commercial, or industrial, welded wire mesh is adaptable to different project requirements. It can be used in floors, walls, driveways, and more.

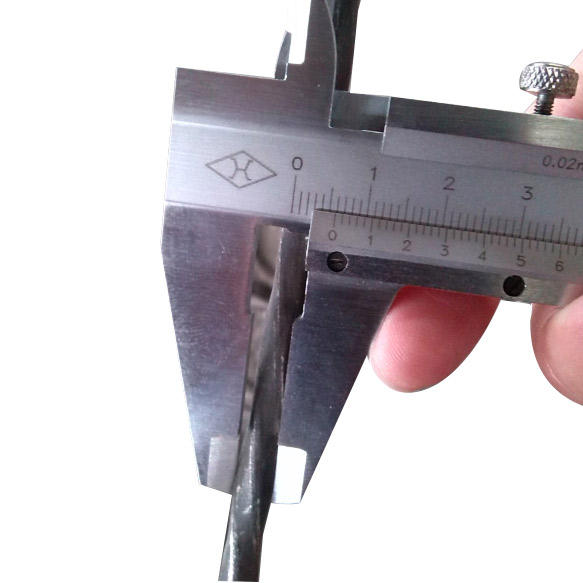

wholesale welded wire mesh panels concrete

5. Reduced Maintenance Structures reinforced with welded wire mesh tend to require less maintenance over time. The increased structural integrity means fewer repairs due to cracking or settling, making it a smart choice for long-term construction investments.

Choosing the Right Welded Wire Mesh Panels

When selecting welded wire mesh panels for concrete projects, it is important to consider several factors

- Wire Gauge and Spacing The gauge of the wire and the spacing within the mesh will depend on the specific load requirements of your project. Thicker wires and tighter spacing are generally used for high-load applications, while lighter meshes may be used for less demanding projects.

- Panel Size Welded wire mesh panels come in various sizes. Choose a size that suits your concrete formwork without excessive cutting, which could add time and labor costs.

- Coating Some wire meshes are coated to enhance corrosion resistance, especially in environments that are exposed to moisture and salts. Evaluating the environmental conditions of the project site can guide decisions on whether a coated option is necessary.

- Supplier Reliability When purchasing wholesale, it’s crucial to work with reputable suppliers. Look for companies that have a history of delivering high-quality products on time. Checking customer reviews and seeking recommendations can help identify reliable sources.

Conclusion

In the realm of construction, welded wire mesh panels play a critical role in ensuring the strength and durability of concrete structures. With the option to purchase these panels wholesale, contractors can enjoy significant savings while benefiting from the reliability and efficiency that welded wire mesh offers. By considering the specific needs of their projects and selecting the right materials, builders can create robust concrete structures that stand the test of time. Ultimately, investing in quality welded wire mesh reinforces not just concrete, but the very foundation of construction success.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025