Nov . 08, 2024 21:33 Back to list

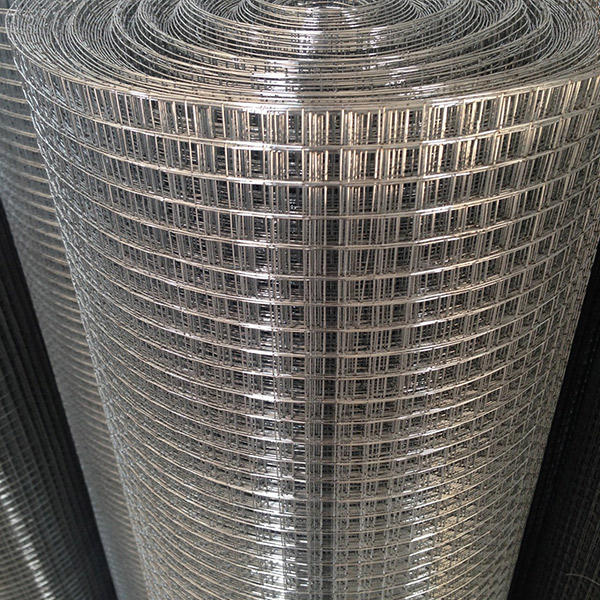

wholesale gi welded wire mesh

The Versatility and Applications of Wholesale GI Welded Wire Mesh

Welded wire mesh has become an essential material across various industries due to its strength, durability, and versatility. Among the different types of welded wire mesh available in the market, galvanized iron (GI) welded wire mesh stands out due to its corrosion resistance and longevity. In this article, we will explore the features, benefits, and applications of wholesale GI welded wire mesh.

What is GI Welded Wire Mesh?

Galvanized iron welded wire mesh is created by welding together strands of iron wire, which are then coated with a layer of zinc to protect against corrosion. This coating can be done either through the hot-dip galvanization process or by electro-galvanization. The hot-dip method provides a thicker layer of zinc, ensuring superior rust resistance, whereas the electro-galvanization method delivers a finer finish. Both types offer excellent protection against environmental factors, making them suitable for a range of applications.

Key Features of Wholesale GI Welded Wire Mesh

1. Corrosion Resistance One of the primary advantages of GI welded wire mesh is its ability to resist rust and corrosion. This feature makes it ideal for use in harsh environments, such as in coastal areas or industries that deal with chemicals.

2. Strength and Durability The welded construction of the mesh enhances its strength, enabling it to withstand heavy loads and impacts. The wires are tightly woven, creating a robust framework that can endure wear and tear over time.

3. Varied Sizes and Specifications Wholesale suppliers often provide a range of sizes and specifications, allowing customers to select the appropriate mesh according to their project needs. This includes different wire diameters, mesh openings, and panel sizes.

4. Cost-Effectiveness Purchasing GI welded wire mesh in wholesale quantities can lead to significant cost savings. Bulk buying often comes with reduced prices per unit, making it a more economical choice for contractors and businesses.

wholesale gi welded wire mesh

Applications of GI Welded Wire Mesh

GI welded wire mesh is utilized in a myriad of applications across various sectors, thanks to its versatility. Some of the most common uses include

- Construction In the construction industry, GI welded wire mesh is commonly used for reinforcement in concrete and masonry structures. It adds tensile strength to slabs, walls, and pavements, reducing the risk of cracking and structural failure.

- Fencing The durability and rust resistance of GI welded wire mesh make it an excellent choice for fencing applications. It is frequently used in agricultural settings to create enclosures for livestock, as well as in residential and commercial properties to enhance security.

- Industrial Applications In factories and warehouses, GI welded wire mesh is often used for creating barriers, machine guards, and storage racks. It safely holds goods in place while still allowing air circulation.

- Horticulture Gardeners and landscapers favor GI welded wire mesh for its use in trellising plants, constructing greenhouses, and creating protective cages around delicate plants to shield them from pests.

- Architectural Features More recently, GI welded wire mesh has found its way into architectural design, where it is used for aesthetic purposes in creating artistic installations, balustrades, and facade elements.

Conclusion

In conclusion, wholesale GI welded wire mesh is a versatile and durable material that offers a wide array of applications across multiple industries. Its corrosion resistance, strength, and cost-effectiveness make it an attractive option for both consumers and businesses. Whether for construction, agricultural fencing, or industrial use, GI welded wire mesh continues to play a crucial role in enhancing the quality and efficiency of various projects. With the ever-growing demand for reliable and durable materials, investing in wholesale GI welded wire mesh is not only a practical decision but also a smart one for ensuring longevity and performance in various applications.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025