Oct . 13, 2024 04:49 Back to list

welding steel mesh manufacturers

Understanding Welding Steel Mesh Manufacturers A Comprehensive Overview

Welding steel mesh has become an integral component across a multitude of industries, offering strength, durability, and versatility. The process of manufacturing welding steel mesh involves the intersection of technology, craftsmanship, and stringent standards to produce a product that meets the diverse needs of construction, agriculture, mining, and more. In this article, we will delve into the world of welding steel mesh manufacturers, exploring their processes, benefits, and the qualities that set them apart in a competitive market.

What is Welding Steel Mesh?

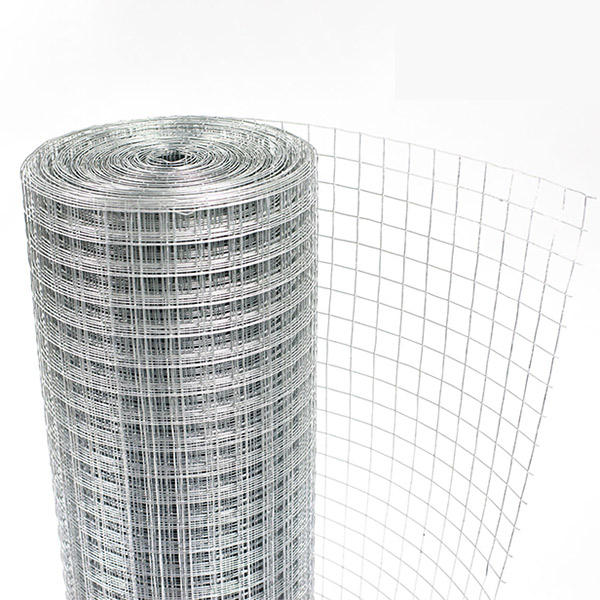

Welding steel mesh, commonly referred to as welded wire mesh or welded wire fabric, is a grid-like structure made from intersecting steel wires that are welded together at their junctions. This robust construction allows for high tensile strength, making it suitable for various applications including reinforced concrete, fences, and industrial flooring. The mesh is available in various sizes and wire gauges, tailored to suit specific structural requirements.

The Manufacturing Process

The production of welding steel mesh typically follows a well-defined process

1. Raw Material Selection Manufacturers start by sourcing high-quality steel wire, which is essential for ensuring the longevity and integrity of the final product. Common materials include low-carbon steel and stainless steel, chosen for their strength and resistance to corrosion.

2. Wire Drawing The sourced wire undergoes a drawing process, where it is pulled through a series of dies to achieve the desired diameter. This step is crucial for ensuring uniformity and consistency in the mesh.

3. Mesh Formation Once the wires are drawn, they are arranged into a grid pattern. The spacing between the wires can be customized based on client specifications and intended use.

4. Welding The intersection points of the laid-out wires are then welded using either electric resistance welding or laser welding techniques. This step not only binds the wires together but also enhances the structural integrity of the mesh.

5. Finishing Treatments After welding, the mesh may undergo various finishing treatments such as galvanization or coating to enhance its corrosion resistance and longevity. This is particularly important for applications exposed to harsh environmental conditions.

6. Quality Control Finally, rigorous quality checks are conducted to ensure that the welded wire mesh meets industry standards and client specifications. This may involve testing for tensile strength, weld integrity, and overall dimensional accuracy.

Benefits of Using Welding Steel Mesh

welding steel mesh manufacturers

Manufactured welding steel mesh offers several advantages

- Strength and Stability The welded intersections create a robust structure capable of withstanding significant loads, making it ideal for use in concrete reinforcement.

- Versatility The adaptability of welded wire mesh allows it to be utilized in a wide range of applications, from construction to landscaping, and even in decorative projects.

- Cost-Effectiveness In comparison to alternative reinforcement methods, welding steel mesh can be a more economical option, reducing the labor and material costs associated with construction projects.

- Ease of Installation The lightweight nature of the mesh simplifies handling and installation, thereby speeding up construction timelines.

Choosing the Right Manufacturer

When selecting a welding steel mesh manufacturer, it is vital to consider several factors

- Experience and Reputation A manufacturer with extensive experience in the industry is more likely to adhere to high-quality standards. Researching customer reviews and case studies can provide insight into their reliability.

- Custom Capabilities Ensure that the manufacturer can produce customized mesh solutions that meet your specific requirements in terms of size, gauge, and coating options.

- Compliance with Standards Verify that the manufacturer adheres to industry standards and certifications, which assures you of the quality and safety of the products.

- Customer Support A manufacturer with strong customer support will be invaluable for addressing inquiries, handling special requests, and providing after-sales service.

Conclusion

Welding steel mesh manufacturers play a crucial role in providing foundational materials for various industries. By understanding the manufacturing process, benefits, and key selection criteria, clients can make informed decisions that affect their projects' overall success. Investing in high-quality welded wire mesh is not only integral to ensuring structural reliability but also contributes to the efficiency and cost-effectiveness of construction and manufacturing processes. As industries continue to evolve, the importance of quality welded steel mesh will undoubtedly remain paramount.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025