Nov . 24, 2024 00:19 Back to list

welded wire mesh sizes for concrete manufacturers

Understanding Welded Wire Mesh Sizes for Concrete Manufacturers

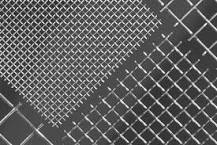

Welded wire mesh is an essential component in the construction and manufacturing industry, particularly for concrete applications. It serves as a reinforcement measure, improving the structural integrity and durability of various concrete products. As concrete manufacturers expand their production capabilities, understanding the different sizes and specifications of welded wire mesh becomes crucial for optimizing their operations and ensuring quality outcomes.

What is Welded Wire Mesh?

Welded wire mesh, also known as welded wire fabric, consists of intersecting wires that are welded together at their junctions. This grid-like structure is commonly made from high-strength steel wires, providing enhanced tensile strength and support to concrete. It is available in various sizes and configurations, allowing manufacturers to select the most suitable mesh for their specific applications.

The Importance of Size in Welded Wire Mesh

When it comes to welded wire mesh, size matters. Different projects have unique requirements concerning the size of the mesh, including its wire gauge, spacing, and sheet dimensions. These factors are critical as they determine the mesh's performance and its ability to resist cracking and deformation under loads.

1. Wire Gauge and Diameter The wire gauge refers to the thickness of the wire used in the mesh. Common gauges include 6, 8, 10, and 12, with lower numbers indicating thicker wire. Thicker wires typically offer greater strength and load-bearing capabilities, making them suitable for heavy-duty applications, such as commercial buildings and industrial flooring. For lighter applications, such as slabs or precast products, thinner wires may suffice.

2. Spacing The spacing of the wires in the mesh is another important consideration. Common spacing options include 4 inches by 4 inches, 6 inches by 6 inches, and 8 inches by 8 inches. Tighter spacing typically provides more reinforcement, which is essential for high-stress areas. Conversely, wider spacing may reduce material costs and weight but could compromise the overall structural integrity in certain scenarios.

welded wire mesh sizes for concrete manufacturers

3. Sheet Dimensions Welded wire mesh is available in various dimensions, typically ranging from 3 feet by 6 feet to 5 feet by 10 feet. The choice of sheet dimensions often depends on the specific application and the size of the concrete components being produced. Larger sheets can cover more area and reduce the number of joints, enhancing overall strength.

Materials and Coating Options

Most welded wire meshes are manufactured from carbon steel, but there are options available coated with materials like galvanized steel or plastic. Galvanized wire mesh offers corrosion resistance, making it ideal for applications exposed to moisture, such as foundations and retaining walls. Manufacturers must consider the environmental conditions of the project site when selecting the appropriate material.

Standards and Regulations

Concrete manufacturers should also be aware of local and international standards governing the production and use of welded wire mesh. Organizations like the American Concrete Institute (ACI) and the American Society for Testing and Materials (ASTM) provide guidelines to ensure that the welded wire used meets specific quality and safety criteria. Familiarizing oneself with these standards can help manufacturers avoid costly mistakes and ensure compliance.

Conclusion

In summary, the selection of the appropriate welded wire mesh size is a critical factor for concrete manufacturers. Understanding the implications of wire gauge, spacing, and sheet dimensions, along with considering material options and compliance with regulations, can lead to better product performance and enhanced structural integrity. As industries continue to evolve and demand higher quality concrete products, manufacturers who invest time in understanding these specifications will likely hold a competitive edge in the marketplace. By prioritizing the right welded wire mesh for their needs, manufacturers can ensure they deliver durable and reliable concrete solutions.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025