Nov . 11, 2024 03:38 Back to list

Suppliers of Welded Wire Mesh Panels for Concrete Applications and Projects

The Importance of Welded Wire Mesh Panels in Concrete Applications

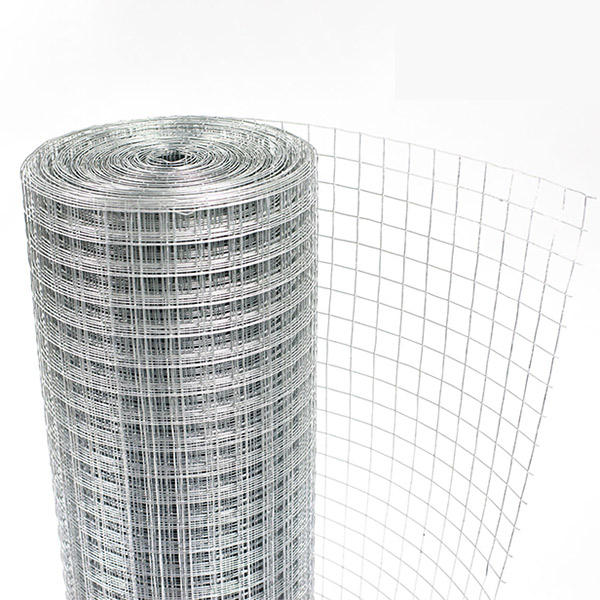

Welded wire mesh panels have become an essential component in various construction and concrete applications. As the demand for durable and efficient building materials continues to rise, suppliers of welded wire mesh panels are stepping up to meet the needs of builders, engineers, and contractors. This article explores the significance of these panels in concrete construction and the reasons why they remain a popular choice among construction professionals.

What are Welded Wire Mesh Panels?

Welded wire mesh panels are made from carbon steel wires that are electrically welded at their intersections. These panels come in various sizes and gauges, making them suitable for numerous applications in construction. Their design allows them to provide strength, reduce cracking, and support concrete structures effectively. They are often used in floors, walls, and other structural elements, serving as a reinforcement to ensure longevity and stability.

Benefits of Using Welded Wire Mesh Panels

1. Enhanced Structural Integrity One of the primary advantages of using welded wire mesh panels is the enhancement of structural integrity in concrete applications. The panels help distribute loads evenly across the concrete slab, thus preventing localized stress and reducing the risks of cracking. This is particularly crucial in areas with heavy traffic or loads, such as industrial floors.

2. Cost-Effective Solution When compared to traditional rebar reinforcement, welded wire mesh offers a more cost-effective solution. The ease of installation results in lower labor costs and shorter construction timeframes. Furthermore, since the panels can be manufactured in various sizes, they can be customized to fit specific project requirements, minimizing waste and optimizing resource use.

3. Versatility Welded wire mesh panels are incredibly versatile and can be employed in numerous construction scenarios, making them a favorite among suppliers. Whether reinforcing concrete slabs, pavements, or precast concrete products, these panels can adapt to various designs and specifications. They are also utilized in fencing and other architectural elements, showcasing their diverse applications.

4. Resistance to Corrosion Many suppliers offer welded wire mesh panels treated with anti-corrosive coatings. This feature significantly extends the life of the mesh, especially in environments prone to moisture and chemicals. This resistance to corrosion is critical in ensuring that concrete structures maintain their strength and integrity over time.

welded wire mesh panels concrete suppliers

Choosing the Right Supplier

When it comes to sourcing welded wire mesh panels for your concrete projects, selecting the right supplier is crucial. Here are a few considerations to keep in mind

- Quality Assurance Look for suppliers who adhere to industry standards and provide products that undergo rigorous quality control. This guarantees that you receive panels that will perform effectively in your specific application.

- Customization Options Many projects require specific dimensions or characteristics in wire mesh panels. A reliable supplier should offer customization options to meet these needs efficiently.

- Timely Delivery Construction schedules are often tight, and delays can lead to increased costs. Choose a supplier with a proven track record for timely delivery to ensure that your project stays on schedule.

- Customer Support A supplier with excellent customer support can help you navigate through the purchasing process, offering guidance on product selection and addressing any concerns that may arise.

Conclusion

Welded wire mesh panels play a crucial role in modern concrete construction, providing strength, durability, and versatility. With numerous benefits, including cost-effectiveness and resistance to corrosion, they are an indispensable component for builders and contractors. By choosing the right suppliers, construction professionals can ensure that they have access to high-quality welded wire mesh panels that meet their project's specific needs, contributing to the overall success and longevity of their structures.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025