Dec . 10, 2024 08:49 Back to list

welded wire mesh panels concrete supplier

The Importance of Welded Wire Mesh Panels in Concrete Construction

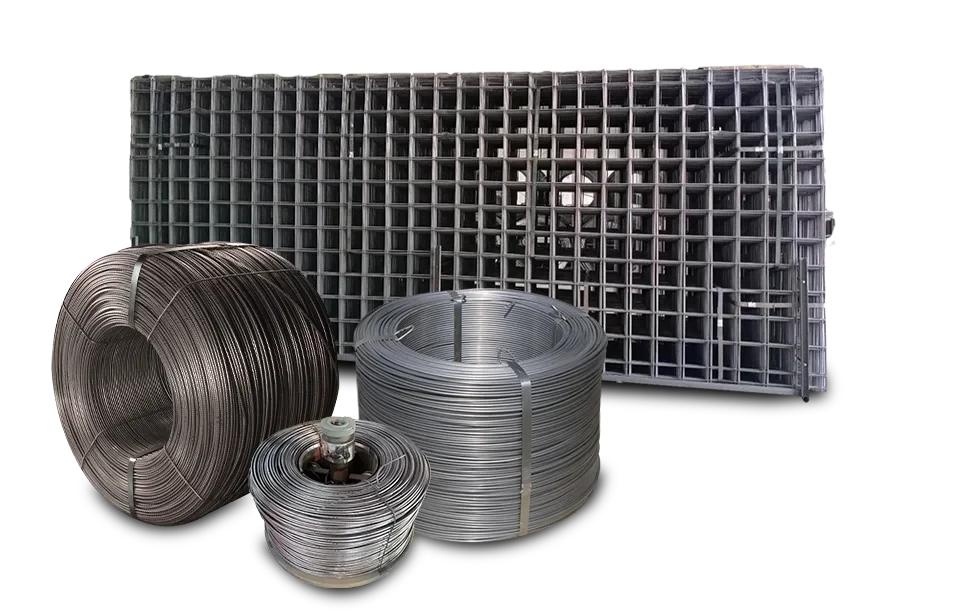

In the realm of modern construction, the use of welded wire mesh panels has become increasingly popular, especially in concrete applications. These panels serve as essential reinforcement materials, providing strength, durability, and structural integrity to various structures. As construction techniques evolve, understanding the significance of welded wire mesh panels in concrete work can greatly enhance project quality and efficiency.

What is Welded Wire Mesh?

Welded wire mesh is a grid of steel wires that are welded together at their intersections, typically creating a square or rectangular mesh pattern. The thickness of the wires and the spacing between them can vary depending on the specific application. These panels come in various sizes and shapes, allowing for versatility in use across different construction projects. They are commonly used in flooring, walls, and other concrete structures to enhance load-bearing capacity.

The Role of Welded Wire Mesh in Concrete

Concrete alone, while robust in compression, can be weak in tension. This is where welded wire mesh panels play a vital role. By incorporating these panels into the concrete mix, contractors significantly improve the tensile strength of the concrete, reducing the likelihood of cracks and ensuring a longer lifespan for the structure.

When placed within the concrete slab or wall, welded wire mesh helps to distribute loads more evenly. This distribution minimizes stress on any single point and alleviates the risk of localized failure, which is critical in large structures like bridges, highways, and high-rise buildings. Moreover, the incorporation of welded wire mesh is a cost-effective way to achieve enhanced strength without the need for heavier, more expensive reinforcement options.

Benefits of Using Welded Wire Mesh Panels

1. Enhanced Durability Structures reinforced with welded wire mesh panels withstand environmental stresses better, maintaining their integrity over time. This is particularly important in regions susceptible to seismic activity or extreme weather conditions.

2. Crack Resistance Implementing welded wire mesh effectively reduces the occurrence and extent of cracking in concrete. This is crucial for maintaining the aesthetic appearance of surfaces, as well as for ensuring they remain safe for use.

3. Ease of Installation Welded wire mesh panels are easy to handle and install, which can lead to significant time savings on the job site. The panels are typically laid out quickly, and their lightweight nature simplifies the overall construction process.

welded wire mesh panels concrete supplier

4. Versatile Applications From residential buildings to large industrial projects, welded wire mesh is suitable for various applications. It can be used in floors, walls, driveways, and even precast concrete elements.

5. Cost Effectiveness Compared to traditional rebar, welded wire mesh can be a more economical option. Its ability to enhance structural integrity means that fewer materials may be needed, translating into savings on labor and material costs.

Choosing the Right Supplier

To maximize the benefits of welded wire mesh panels in concrete applications, it is essential to select a reliable supplier. Quality control during the manufacturing process is critical, as inferior products can compromise structural integrity. When choosing a supplier, consider factors such as

- Reputation Look for suppliers with positive reviews and a track record of reliability in the construction industry.

- Product Quality Verify the quality standards of the welded wire mesh offered. Ensure that the materials meet or exceed relevant construction codes and regulations.

- Customization A good supplier should offer customizable options to meet the specific needs of your project.

- Customer Support A knowledgeable supplier can provide guidance on product selection and proper installation techniques, supporting your project from start to finish.

Conclusion

Welded wire mesh panels are an indispensable component of modern concrete construction, providing enhanced strength, durability, and cost-efficiency. Their versatility makes them suitable for a wide range of applications, ensuring that structures can withstand both time and environmental stresses. By partnering with a reputable supplier, contractors can leverage the full benefits of welded wire mesh panels, ultimately contributing to the success and longevity of their projects. As the construction industry continues to evolve, the importance of quality reinforcement materials like welded wire mesh panels cannot be overstated.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory | Structural Strength & Corrosion Resistance

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory-Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Durable, Corrosion-Resistant Solutions

NewsSep.01,2025

-

Welded Wire Mesh for Industrial - Anping Puersen | Durability, Corrosion Resistance

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsSep.01,2025

-

Welded Wire Mesh - Anping Puersen|Durability&Corrosion Resistance

NewsSep.01,2025