Nov . 13, 2024 02:02 Back to list

welded wire mesh in concrete slab manufacturers

Benefits of Using Welded Wire Mesh in Concrete Slabs

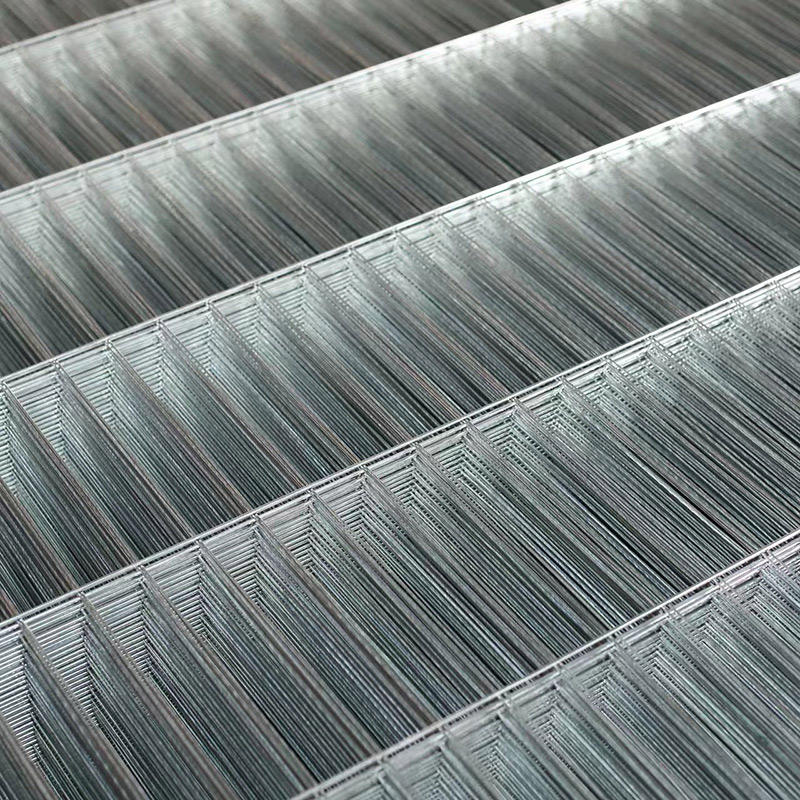

Welded wire mesh has become a popular choice among construction professionals for reinforcement in concrete slabs. Its unique composition and structure provide significant advantages that enhance the integrity and durability of concrete elements.

What is Welded Wire Mesh?

Welded wire mesh is a grid-like framework made from the intersection of high-quality steel wires that are electrically welded at their junctions. This construction method ensures uniform strength distribution throughout the mesh, making it an excellent reinforcing material for concrete applications. The mesh is available in various sizes and thicknesses, allowing manufacturers to tailor it to specific project requirements.

Strength and Stability

One of the primary benefits of using welded wire mesh in concrete slabs is its ability to provide enhanced tensile strength. Concrete is naturally strong under compression but weak under tension. By incorporating welded wire mesh, the tensile strength is significantly improved, reducing the risk of cracks and structural failures. This is particularly crucial in areas subjected to heavy loads or dynamic forces, such as industrial floors and highways.

Ease of Installation

Welded wire mesh is easy to install, making it a preferred choice for contractors. Unlike traditional reinforcement methods that require extensive labor, welded wire mesh can be quickly laid out across the slab area. With pre-cut sizes available, contractors can reduce onsite labor costs and expedite the project timeline. The mesh remains in place easily during the pouring of concrete, ensuring a consistent embedment throughout.

welded wire mesh in concrete slab manufacturers

Cost-Effectiveness

Using welded wire mesh can lead to significant cost savings in large construction projects. Its durability reduces the need for future repairs or replacements, ultimately lowering long-term maintenance costs. Additionally, the ease of installation minimizes labor expenses, allowing budget-conscious project managers to achieve their financial goals.

Sustainability Factors

With the growing emphasis on sustainable construction practices, welded wire mesh contributes positively to this trend. The material is made from recyclable steel, and its longevity means that less material is needed over time. The energy costs associated with manufacturing and transportation are also lower compared to other forms of reinforcement, making it an eco-friendly choice.

Versatility in Applications

Welded wire mesh is not only advantageous in concrete slabs but also versatile in its applications. It is commonly used in various structures such as pavements, foundations, walls, and roofing systems. Its adaptability makes it suitable for residential, commercial, and industrial projects alike.

Conclusion

In conclusion, welded wire mesh is an essential material in modern construction, especially for concrete slabs. With its strength, ease of installation, cost-effectiveness, sustainability, and versatility, it serves as a reliable solution for enhancing the durability of concrete structures. As more manufacturers recognize these benefits, the use of welded wire mesh in construction is likely to increase, paving the way for safer and more robust buildings.

-

Hot Dipped Galvanized Steel Grating Durable & Corrosion-Resistant Solutions

NewsMay.31,2025

-

Plastic-Coated Hexagonal Wire Mesh Manufacturer Durable Solutions

NewsMay.31,2025

-

Reinforced Concrete Expanded Metal Mesh Suppliers & Factories High-Strength

NewsMay.31,2025

-

Galvanized Steel Wire High-Strength, Rustproof Material & Suppliers

NewsMay.30,2025

-

1 Inch Hexagonal Wire Mesh Heavy-Duty Factories & Suppliers

NewsMay.30,2025

-

Green PVC Coated Wire Durable, Weather-Resistant Electrical Solutions

NewsMay.30,2025