Nov . 13, 2024 14:26 Back to list

welded wire mesh for industry manufacturer

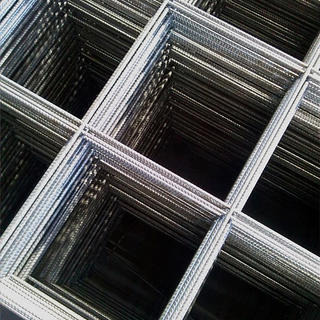

The Importance of Welded Wire Mesh in Industrial Applications

Welded wire mesh is a versatile and robust product essential for various industrial applications. Manufactured from high-quality steel wires that are welded together at their intersection points, welded wire mesh offers numerous advantages over traditional fencing and support structures. In this article, we will explore the various uses, benefits, and selection criteria for welded wire mesh, particularly in industrial settings.

Applications of Welded Wire Mesh

1. Construction and Civil Engineering In the construction industry, welded wire mesh serves as an effective reinforcement material in concrete elements. Using welded wire mesh enhances the tensile strength of concrete, making it an ideal choice for floor slabs, walls, and pavement. It minimizes the risk of cracking and provides stability to structures, contributing to durability and longevity.

2. Fencing Solutions Welded wire mesh is widely used as a fencing solution in industrial environments. Its uniform design and strength provide a secure barrier against unauthorized access while allowing visibility. Industries such as manufacturing, agriculture, and mining utilize welded wire mesh fences to safeguard their premises and assets. Various mesh sizes and gauges can be tailored to meet specific security requirements.

3. Animal Enclosures and Agricultural Use In agriculture, welded wire mesh is commonly used for animal enclosures, ensuring the safety and well-being of livestock. It provides a solid barrier against predators while allowing adequate airflow and visibility. Additionally, welded wire mesh can be utilized for garden fencing, covering compost bins, and securing plant nurseries against pests.

4. Industrial Equipment and Storage Welded wire mesh is an excellent solution for creating custom storage systems in warehouses and factories. It can be used to construct shelving units, tool racks, and partitioning systems, optimizing space and organization. Furthermore, welded wire mesh can support heavy machinery and act as a protective casing for equipment.

5. Filtration and Separation Welded wire mesh is widely used in filtration systems across industries, including food processing, pharmaceuticals, and oil and gas. Its fine mesh can effectively filter out impurities while allowing liquids or gases to flow through. The durability of the mesh also ensures it can withstand high pressure and corrosive environments.

Benefits of Welded Wire Mesh

- Strength and Durability Welded wire mesh is known for its robustness. The welding process creates strong bonds at the intersections, which significantly enhances its strength compared to woven wire mesh. This makes it particularly suitable for heavy-duty applications.

welded wire mesh for industry manufacturer

- Cost-Effectiveness Due to its durability and longevity, welded wire mesh is a cost-effective solution for many industrial applications

. It requires less maintenance and replacement over time, which translates to lower long-term costs.- Versatility Welded wire mesh is available in various sizes, shapes, and materials. Manufacturers can customize it to meet specific requirements, making it an adaptable solution for nearly any industrial need.

- Ease of Installation The uniform structure of welded wire mesh allows for straightforward installation. It can be easily cut to size and shaped accordingly, reducing labor costs and time spent on setup.

Selecting the Right Welded Wire Mesh

When selecting welded wire mesh for industrial applications, several factors must be considered

1. Material Type The choice of material, such as galvanized steel, stainless steel, or vinyl-coated wire, will depend on the specific environmental conditions and the desired durability. Galvanized wire offers corrosion resistance, suitable for outdoor use, while stainless steel is ideal for applications requiring high hygiene standards.

2. Mesh Size and Gauge The mesh size and wire gauge will significantly impact the strength and functionality of the final product. A careful assessment of the intended use will help determine the appropriate specifications.

3. Coating Options Depending on the application, coatings can enhance the longevity and aesthetic aspect of welded wire mesh. Options such as powder coating or PVC coating can provide additional protection from environmental factors and increase visual appeal.

Conclusion

Welded wire mesh is an essential component of various industrial applications, offering strength, versatility, and cost-effectiveness. Its ability to provide reinforcement, security, and organization makes it a preferred choice in construction, fencing, agriculture, and equipment storage. As industries continue to evolve, the demand for durable and adaptable solutions like welded wire mesh will remain high, making it a critical element in the development of modern industrial practices.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025