Nov . 25, 2024 07:05 Back to list

High-Quality Welded Wire Mesh in 9 Gauge from Leading Manufacturer

Understanding Welded Wire Mesh 9 Gauge A Comprehensive Overview

Welded wire mesh is a versatile construction material used across various industries, from agriculture to commercial construction. Among the various specifications available, 9-gauge welded wire mesh holds a significant place because of its strength, durability, and adaptability. This article will explore the key aspects, benefits, and applications of 9-gauge welded wire mesh, particularly focusing on factory production.

What is Welded Wire Mesh?

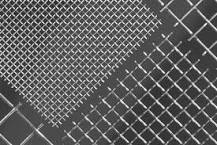

Welded wire mesh consists of wire strands that are welded at their intersections, creating a grid-like structure. The gauge refers to the thickness of the wire; in this case, a 9-gauge wire is approximately 0.148 inches in diameter. This thickness provides substantial strength and makes the mesh suitable for demanding applications. Typically manufactured using high-quality steel, the mesh can be galvanized or coated to enhance its resistance to corrosion and environmental wear.

Advantages of 9-Gauge Welded Wire Mesh

1. Strength and Durability With its thicker wire, 9-gauge welded wire mesh offers enhanced tensile strength compared to thinner gauges. This feature makes it ideal for heavy-duty applications where structural integrity is crucial. Whether used in concrete reinforcement or as a fence, 9-gauge mesh can withstand significant loads and stresses.

2. Versatility 9-gauge welded wire mesh is available in various sizes and configurations, allowing it to be customized for specific needs. Factories can produce different widths, lengths, and mesh openings, making it adaptable for diverse projects, such as livestock enclosures, security fencing, or industrial flooring.

3. Cost-Effectiveness Although the initial investment may be higher for thicker mesh, the long-term benefits often outweigh the costs. The durability and strength of 9-gauge welded wire mesh mean less frequent replacements and repairs, leading to overall savings.

4. Ease of Installation The welded design allows for straightforward installation. Depending on the application, sections can easily be cut to size, and the mesh can be connected using various methods, including welding or lacing. This factor minimizes labor time and costs on the job site.

welded wire mesh 9 gauge factory

Applications of 9-Gauge Welded Wire Mesh

1. Construction In the construction industry, 9-gauge welded wire mesh is commonly used for reinforcing concrete slabs, walls, and other structures. Its strength promotes stability and longevity in building projects.

2. Fencing The robustness of 9-gauge welded wire mesh makes it an excellent choice for fencing applications. It not only provides security for industrial facilities but also serves well in agricultural settings for containing livestock and protecting crops.

3. Agriculture Farmers frequently use welded wire mesh for various purposes, including animal enclosures, plant support, and even in greenhouses. The mesh helps in maintaining a safe environment for livestock while allowing air and light to penetrate.

4. Industrial Usage In warehouses and factories, 9-gauge welded wire mesh can be used for storage racks, shelving, and partitions. Its ability to support heavy loads makes it an ideal material for organizing equipment and maintaining safety within industrial spaces.

Manufacturing Process

The manufacturing of 9-gauge welded wire mesh involves several steps. First, high-quality wire is drawn to the desired gauge. Next, the wire is cut and arranged into a grid format. Advanced welding machinery is then used to fuse the wires at their intersections, ensuring a solid and durable bond. Finally, the mesh may undergo a protective coating process to enhance its resistance to rust and other environmental factors.

Conclusion

In conclusion, 9-gauge welded wire mesh is a reliable and robust material suitable for various applications across multiple sectors. Its strength, durability, versatility, and cost-effectiveness make it an ideal choice for construction and agricultural projects. As industries continue to seek efficient and reliable materials, welded wire mesh remains a steadfast option, demonstrating that quality and performance can go hand in hand with practicality. Whether for building, fencing, or agricultural use, the importance of quality manufacturing cannot be overstated, ensuring that the final product meets the specific requirements of each project.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025