Oct . 09, 2024 22:07 Back to list

welded wire mesh 9 gauge factories

Understanding Welded Wire Mesh A Focus on 9 Gauge Factories

Welded wire mesh has become an essential material in various industries due to its versatility, strength, and durability. Among the different specifications, 9 gauge welded wire mesh is particularly significant for its robust characteristics and a wide range of applications. This article delves into the intricacies of 9 gauge welded wire mesh and the role factories play in its production.

What is Welded Wire Mesh?

Welded wire mesh consists of a grid made from steel wires that are welded together at intersections. This method of construction provides enhanced strength compared to traditional wire fencing materials. The gauge of the wire indicates its thickness, with lower numbers signifying thicker wires. Consequently, 9 gauge wire, which measures approximately 0.148 inches in diameter, offers excellent load-bearing capacity and resistance to bending and breaking.

Applications of 9 Gauge Welded Wire Mesh

The 9 gauge welded wire mesh is particularly popular in applications where strength and durability are paramount. This type of mesh is widely used in

1. Construction Industry 9 gauge welded wire mesh is commonly utilized as reinforcement for concrete slabs, walls, and other structures. Its strength ensures that concrete retains its structural integrity and can withstand various stresses.

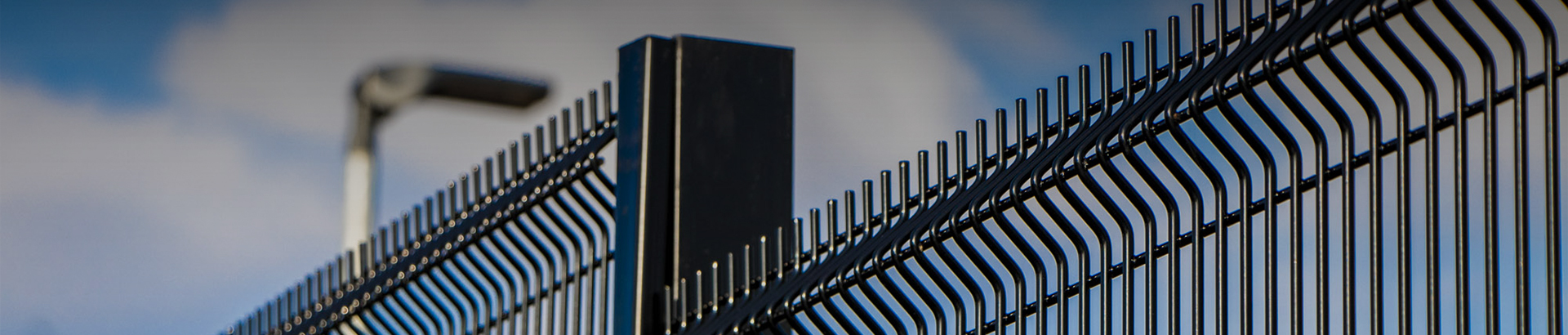

2. Fencing Solutions Many construction and agricultural projects incorporate 9 gauge welded wire mesh for fencing. Its sturdy design provides security for properties, livestock, and crops while allowing visibility and ventilation.

3. Industrial Uses Factories often require robust barriers and partitions, which can be effectively created using 9 gauge welded wire mesh. This mesh is not only strong but also resistant to corrosion, making it ideal for manufacturing environments.

4. Animal Cages and Enclosures The size of the openings in 9 gauge welded wire mesh can be customized, making it suitable for creating secure animal enclosures. It ensures that animals are safe while allowing for air circulation.

welded wire mesh 9 gauge factories

5. Landscaping and Garden Applications Gardeners and landscapers also benefit from 9 gauge welded wire mesh, using it for trellises, plant supports, and garden fencing.

The Manufacturing Process

Factories that specialize in producing 9 gauge welded wire mesh adhere to stringent quality control measures to ensure that the final product meets industry standards. The manufacturing process involves several key steps

1. Wire Drawing Raw steel is processed into thin wires of the desired gauge, in this case, 9 gauge. The metal is drawn through a series of dies to achieve the required thickness.

2. Welding The wires are then arranged in a grid pattern and welded at the intersections using electric welding techniques. This creates a strong bond that enhances the overall integrity of the mesh.

3. Surface Treatment To improve corrosion resistance, the welded mesh is often subjected to surface treatments such as galvanizing or applying protective coatings. This step is crucial, especially for outdoor applications.

4. Quality Inspection After production, the mesh undergoes thorough testing to assess its strength and integrity. Factories implement strict inspection protocols to ensure that only high-quality welds and materials are used.

5. Customization Many factories also offer customization options, allowing customers to specify dimensions, mesh size, and coating preferences to meet their unique requirements.

Conclusion

Welded wire mesh, especially in the form of 9 gauge, plays a vital role across a variety of industries. Its strength, durability, and versatility make it an essential material for construction, agriculture, and industrial applications. Factories dedicated to producing this type of mesh ensure that high standards of quality and innovation are maintained, catering to a growing market's needs. As industries continue to evolve, the demand for reliable, robust materials like 9 gauge welded wire mesh is poised to increase, solidifying its place as a cornerstone in modern construction and related sectors.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025