Dec . 03, 2024 17:49 Back to list

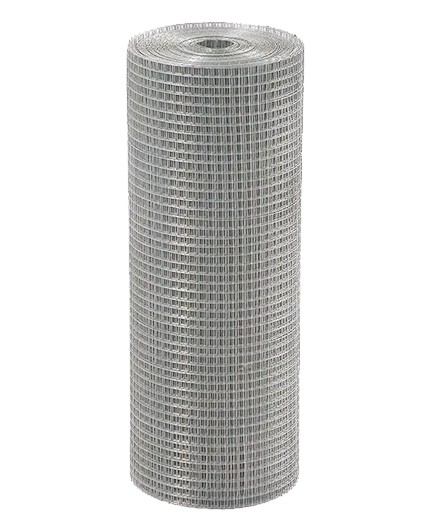

50x50 Welded Wire Mesh Supplier for Versatile Construction Applications

The Importance of Welded Wire Mesh Focus on 50x50 Suppliers

Welded wire mesh is a versatile and widely used material in various industries, underpinning construction, agriculture, and manufacturing with its strength and durability. Among the various specifications available in welded wire mesh, the 50x50 mm size stands out due to its optimal balance between structural integrity and flexibility, making it a preferred choice for suppliers and end-users alike.

Understanding Welded Wire Mesh

Welded wire mesh is created by intersecting horizontal and vertical steel wires, which are then welded at their junctions to form a grid. The dimensions, such as the 50x50 mm mesh size, refer to the spacing between the wires. Due to its robust construction, welded wire mesh is resistant to deformation and can withstand significant loads, making it ideal for a range of applications.

Applications of 50x50 Welded Wire Mesh

1. Construction and Civil Engineering One of the primary applications of 50x50 welded wire mesh is in reinforced concrete construction. It is incorporated into slabs, walls, and pavements to enhance structural strength and prevent cracking. The mesh distributes loads more evenly, improving the overall durability of buildings and other infrastructures.

2. Fencing Solutions The 50x50 mm welded wire mesh is also widely used in fencing applications. Its strength deters unwanted intrusions, while the grid design allows for visibility without compromising security. This makes it an ideal choice for residential, commercial, and industrial fencing.

3. Agricultural Uses In agriculture, welded wire mesh serves multiple functions, such as constructing livestock enclosures, crop protection nets, and storage solutions. The open grid allows for effective ventilation and visibility, creating a comfortable environment for animals while protecting crops from pests and environmental factors.

4. Manufacturing and DIY Projects For manufacturers and DIY enthusiasts, 50x50 welded wire mesh offers a reliable solution for a myriad of projects. From shelving units to manufacturing fixtures, the mesh provides support and structure, facilitating a wide range of creative applications.

welded wire mesh 50x50 supplier

Choosing a Reliable Supplier

Selecting the right supplier for 50x50 welded wire mesh is crucial to ensuring quality and meeting project specifications. Here are key factors to consider when choosing a supplier

1. Quality Assurance Look for suppliers that adhere to industry standards and certifications. High-quality welded wire mesh should possess adequate tensile strength and corrosion resistance. Request samples to verify the product quality before making bulk purchases.

2. Customization Options Different projects might require specific dimensions, coatings, or finishes. Reliable suppliers often offer customization services to meet diverse requirements. Ensure that the supplier can accommodate any specific needs you may have.

3. Production Capacity Assess the supplier's production capabilities. For large-scale projects, it’s essential to choose a supplier who can meet high volume demands without compromising on quality or delivery timelines.

4. Pricing and Value While price is an important factor, it’s essential to balance cost with quality. Evaluate the supplier’s pricing structure and ensure that you are getting value for your investment. Remember that the cheapest option might not always provide the best quality.

5. Customer Support and Service Good customer service can significantly enhance your purchasing experience. Choose a supplier that is responsive to inquiries and can provide assistance throughout the purchasing and delivery process.

Conclusion

Welded wire mesh, particularly the 50x50 mm variant, plays an essential role in various industries due to its strength, flexibility, and diverse applications. By selecting a reputable supplier, you can ensure that you receive high-quality products that effectively meet your project's needs. Whether for construction, agriculture, or manufacturing, investing in reliable welded wire mesh is a decision that enhances safety, durability, and functionality in your projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025