Nov . 01, 2024 02:10 Back to list

Welded Wire Mesh 100x100mm Custom Manufacturing Solutions for Various Applications

Exploring the Advantages of Welded Wire Mesh 100x100mm from Factories

Welded wire mesh has become an essential component in various construction and industrial applications, and one of the most popular formats is the 100x100mm variant. This article delves into the benefits of welded wire mesh, particularly the 100x100mm specification, produced by factories dedicated to high-quality manufacturing.

What is Welded Wire Mesh?

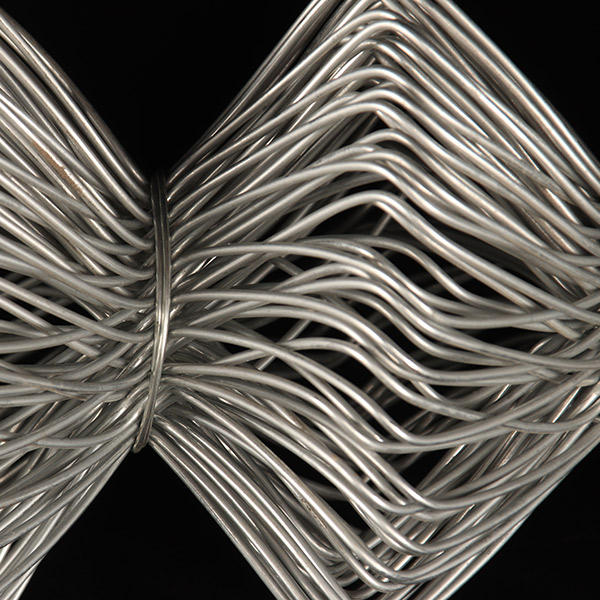

Welded wire mesh consists of longitudinal and transverse wires welded together at intersections to form a grid-like structure

. The 100x100mm specification refers to the spacing between the wires, with each square measuring 100mm by 100mm. This specific layout offers a perfect balance between support and flexibility, making it suitable for a multitude of applications.Advantages of 100x100mm Welded Wire Mesh

1. Strength and Durability One of the most significant benefits of welded wire mesh is its strength. The welding process creates a robust grid that can withstand heavy loads and resist deformation. This is particularly important in construction projects where structural integrity is paramount.

2. Versatility The 100x100mm mesh size makes it highly versatile. This specification is ideal for various applications, including concrete reinforcement, animal enclosures, fencing, and even architectural projects. It can easily adapt to different materials and structures, making it a go-to choice for builders and designers.

3. Cost-Effectiveness Factories that produce welded wire mesh often benefit from economies of scale. This means that the cost of manufacturing is lower, enabling suppliers to offer competitive pricing. For contractors and builders, this translates to significant savings on material costs without compromising on quality.

welded wire mesh 100x100mm factory

4. Easy Installation Welded wire mesh is relatively easy to handle and install. It comes in various sizes and can be cut, bent, or shaped to fit specific project requirements. The installation process is streamlined, saving time and labor costs, thereby enhancing overall project efficiency.

5. Corrosion Resistance Many factories utilize galvanized steel or offer coatings that enhance the lifespan of welded wire mesh. This corrosion resistance is particularly beneficial in environments that are exposed to moisture and chemical elements, ensuring that the mesh maintains its strength and performance over time.

6. Environmental Benefits Increasingly, welded wire mesh manufacturers are focusing on sustainable practices. The production process can reuse materials and generate less waste, which is a significant advantage for environmentally conscious projects.

Choosing the Right Factory

When opting for welded wire mesh, selecting a reliable factory is crucial. Look for manufacturers with a reputation for quality and compliance with international standards. Read reviews, request certifications, and ensure that the factory offers comprehensive customer support and flexible order quantities.

Conclusion

Welded wire mesh in a 100x100mm format is an invaluable resource in construction and industrial applications. Its unmatched strength, versatility, and cost-effectiveness make it the preferred choice for many builders and contractors. With the added benefits of easy installation and corrosion resistance, investing in high-quality welded wire mesh from reputable factories is a decision that pays off, both in the short term and long-term durability of structures. As construction continues to evolve, the demand for reliable materials like welded wire mesh will undoubtedly grow, reinforcing its role in modern engineering and design.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025