Nov . 14, 2024 23:38 Back to list

welded wire fabric concrete factory

The Role of Welded Wire Fabric in Concrete Manufacturing

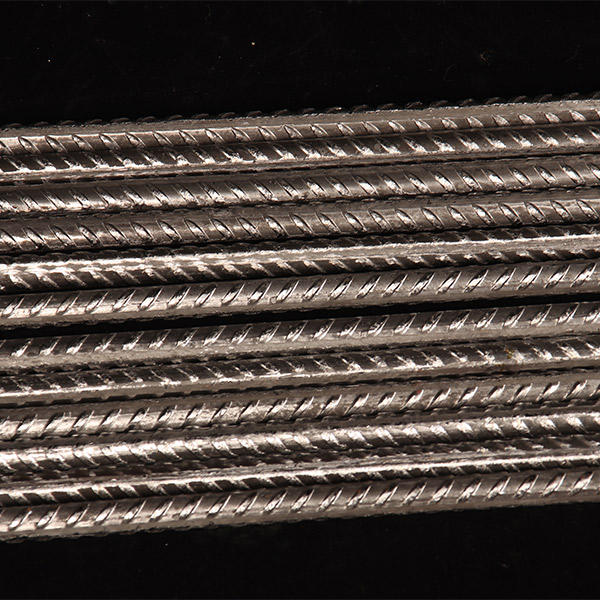

Welded wire fabric (WWF) has become an essential component in the construction industry, particularly in the realm of concrete manufacturing. This versatile material, composed of steel wires welded together at various intervals, offers numerous advantages that enhance the structural integrity and durability of concrete structures. As a result, many concrete factories have begun to incorporate WWF into their production processes.

One of the primary benefits of using welded wire fabric is its ability to evenly distribute loads across concrete slabs and walls. By providing a uniform reinforcement throughout the structure, WWF helps to minimize cracking and mechanical failures, which are common issues in traditional concrete applications. This characteristic is particularly valuable in areas subject to heavy loads or dynamic forces, such as bridges, industrial floors, and pavements. The incorporation of WWF thus leads to longer-lasting infrastructures and reduced repair costs over time.

Moreover, welded wire fabric facilitates a more efficient construction process. Manufacturing concrete products with WWF can significantly speed up the building process by pre-integrating the reinforcement into slab and wall systems. This reduces the time and labor required for installation, allowing construction teams to complete projects more rapidly. In today's fast-paced construction environment, the ability to streamline operations without compromising quality is a critical asset.

Additionally, WWF is cost-effective when compared to traditional rebar. While rebar installation typically requires more labor-intensive processes, WWF can be pre-fabricated in controlled environments, resulting in lower material waste and enhanced precision. Concrete factories that adopt WWF can therefore optimize their production lines and enjoy greater profitability through reduced labor costs and improved resource management.

welded wire fabric concrete factory

The application of welded wire fabric is not limited to industrial uses. It is also widely utilized in residential construction. For example, WWF is frequently employed in the formation of driveways, patios, and even foundations. The flexibility of WWF allows for various design options, making it an attractive choice for homeowners looking to enhance their property while ensuring durability and safety.

In response to environmental concerns, many concrete factories have started to explore eco-friendly production methods, and WWF aligns perfectly with these initiatives. By using welded wire fabric, manufacturers can produce concrete that boasts excellent tensile strength without the need for excessive amounts of material. This not only conserves natural resources but also minimizes the carbon footprint associated with concrete production.

As urbanization continues to rise, the demand for durable, efficient, and sustainable construction solutions is more pressing than ever. Welded wire fabric stands out as a practical reinforcement choice for concrete, supporting the industry's trend toward modernization and sustainability.

In conclusion, the integration of welded wire fabric into concrete manufacturing provides multiple advantages that drive the construction industry forward. With its ability to enhance structural integrity, reduce labor costs, speed up project timelines, and contribute to sustainable practices, WWF is a vital component that can help meet the increasing demands of modern building projects. Concrete factories embracing this innovative material will undoubtedly see improved performance, increased efficiency, and a positive impact on their bottom line. As the industry evolves, welded wire fabric will undoubtedly play an integral role in shaping the future of concrete construction.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025