Sep . 25, 2024 02:54 Back to list

welded steel mesh panel manufacturer

Understanding Welded Steel Mesh Panel Manufacturing

Welded steel mesh panels have become an essential component in various sectors, including construction, agriculture, and industrial applications. These panels are renowned for their strength, durability, and versatility. This article explores the manufacturing process of welded steel mesh panels, their applications, advantages, and factors influencing the choice of a manufacturer.

Manufacturing Process

The manufacturing of welded steel mesh panels involves several key steps. Initially, high-quality steel wires are selected, often with varying diameters depending on the intended use of the mesh. These wires are processed through a series of machines that cut them to the required lengths.

Once the wires are cut, they are arranged in a grid-like pattern. This grid design is crucial, as it determines the strength and stability of the final product. The wires are then welded together at their intersections using electric resistance welding techniques. This method ensures a firm bond, resulting in a panel that can withstand substantial stress and strain.

After the welding process, the panels undergo several quality checks. These checks include visual inspections and tensile tests to ensure that the welded joints are strong and that the panel meets industry standards. Following the quality assurance phase, the panels may be coated with a protective layer of galvanization or other finishes to enhance durability and resistance to corrosion.

Applications

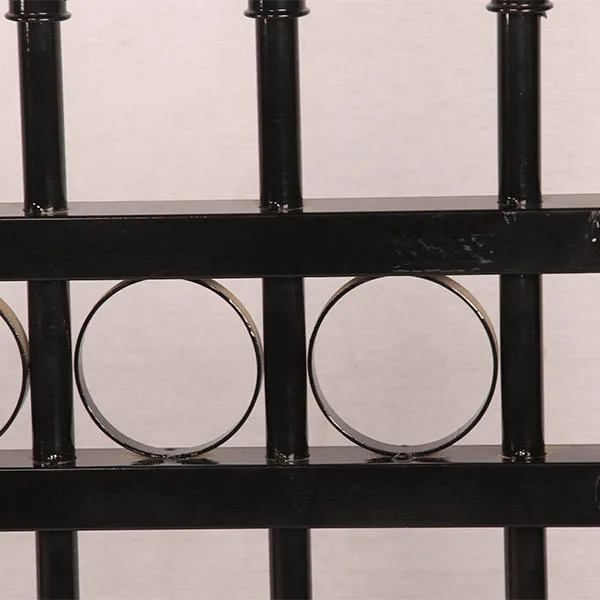

Welded steel mesh panels serve a multitude of purposes. In construction, they are commonly used for reinforcing concrete structures, creating a robust framework that adds stability and support. Additionally, these panels are employed in the production of fencing for residential, agricultural, and industrial properties.

welded steel mesh panel manufacturer

In agriculture, welded steel mesh is frequently used in the construction of animal enclosures, storage cages, and garden fencing

. The panels provide a secure environment for livestock and crops, protecting them from external threats while also ensuring optimal ventilation.Moreover, in industrial settings, these panels are used for safety barriers, security fencing, and partitioning within warehouses. Their versatility and strength make them suitable for various applications, allowing manufacturers to tailor solutions based on specific client needs.

Advantages

One of the primary advantages of welded steel mesh panels is their outstanding strength-to-weight ratio. This property ensures that structures built with these panels can withstand heavy loads while remaining lightweight and easy to handle. Additionally, the uniformity of the grid pattern allows for consistent performance across the entire panel.

Another significant advantage is the ease of installation. Welded panels can be prefabricated to required sizes, reducing labor costs and minimizing installation time. Furthermore, their resistance to corrosion, especially when coated with galvanization, contributes to their long lifespan, making them a cost-effective choice in the long run.

Choosing the Right Manufacturer

Selecting the right manufacturer for welded steel mesh panels is critical to ensuring high-quality products. When considering a manufacturer, it is essential to evaluate their experience in the industry, the quality of materials they use, and their commitment to quality assurance practices. A reputable manufacturer should also be able to provide customization options to meet specific requirements.

In conclusion, welded steel mesh panels are a remarkable solution for a wide range of applications, thanks to their strength, durability, and versatility. Understanding the manufacturing process, applications, and choosing a reliable manufacturer will help ensure the successful use of these panels in various projects. As the necessity for robust and reliable materials continues to grow, welded steel mesh panels will likely remain a preferred choice in multiple industries.

-

Leading Diamond Steel Grating Factory - Durable & Custom

NewsAug.10,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Durable, Versatile, Reliable

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen | Durable Fencing Solution

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable, Versatile, Cost-Effective

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd. | Durable, Versatile, Reliable

NewsAug.09,2025

-

Welded Wire Mesh for Industry Factory | Quality & Custom Solutions

NewsAug.09,2025