Oct . 14, 2024 08:06 Back to list

Welded Mesh Solutions for Bridge Construction and Manufacturing Industries

The Importance of Welded Mesh in Bridge Factories

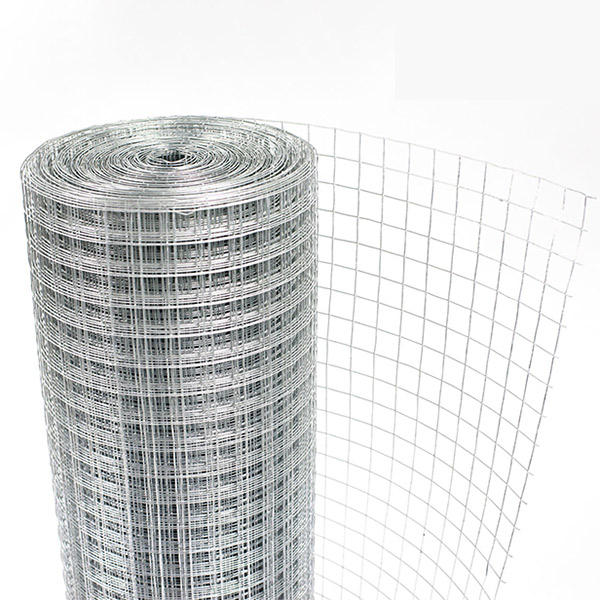

Welded mesh, a versatile and durable material, plays a crucial role in the construction of bridges. This interconnected grid of wire, typically made from high-quality steel, offers a variety of advantages that contribute to the strength, stability, and longevity of bridge structures. In this article, we will explore the significance of welded mesh in bridge factories and how it enhances the construction process.

Composition and Production of Welded Mesh

Welded mesh is manufactured by welding together wires at various intersections, forming a grid pattern. The welding process creates a strong bond between the wires, ensuring that the mesh can withstand intense pressure and stress while remaining flexible enough to adapt to various designs and loads. Depending on the application, manufacturers can customize the size, spacing, and thickness of the wires to meet specific project requirements.

Bridge factories often utilize welded mesh for reinforcing concrete, as it provides an efficient way to distribute load evenly across components. The steel wires used in welded mesh exhibit remarkable tensile strength, and this quality makes them an ideal choice for structures that experience dynamic and static forces, such as bridges.

Advantages of Welded Mesh in Bridge Construction

1. Structural Integrity One of the primary benefits of welded mesh is its ability to enhance the structural integrity of a bridge. By incorporating welded mesh into the concrete, engineers can minimize the risk of cracking and deformation over time. The mesh acts as a reinforcement barrier that distributes weight evenly, resulting in improved load-bearing capacity.

2. Cost-Effective Solution In the competitive landscape of construction, cost management is crucial. Welded mesh is not only affordable but also reduces labor costs associated with traditional reinforcement methods. Its easy handling and installation streamline the construction process, allowing workers to save time without compromising quality.

welded mesh for bridge factories

3. Durability and Longevity Bridges are subject to harsh environmental conditions, including varying weather patterns and heavy traffic loads. The corrosion-resistant properties of welded mesh prolong the lifespan of the structures, ensuring they remain safe and functional for decades. With proper treatment, welded mesh can withstand rust and deterioration, making it a smart investment for bridge manufacturers.

4. Versatility Welded mesh is suitable for various applications within bridge construction, such as slabs, beams, and retaining walls. Its adaptability allows engineers to design complex structures tailored to specific needs while maintaining safety and compliance with regulatory standards.

5. Enhanced Safety The incorporation of welded mesh enhances the safety of bridge structures. By reducing the likelihood of structural failures, it minimizes the risks associated with heavy loads and environmental impacts. This focus on safety is paramount in bridge design, as any compromise can have severe consequences.

Case Studies and Applications

Several iconic bridges around the world utilize welded mesh in their construction. For instance, the use of welded wire reinforcement in the concrete slabs of major highway bridges has proven effective in dispersing stress and preventing cracking. Additionally, welded mesh plays a vital role in the construction of pedestrian bridges, where safety and durability are of utmost importance.

Innovative bridge factories continuously explore new welding techniques and wire materials to enhance the performance of welded mesh. Research and development in this field aim to create lighter yet stronger mesh options, further improving the efficiency of bridge construction.

Conclusion

In conclusion, welded mesh is an indispensable component in the field of bridge construction. Its impressive strength, durability, and versatility make it a preferred choice for engineers and manufacturers alike. As bridge factories continue to evolve, the role of welded mesh will undoubtedly expand, further contributing to the safety and longevity of our bridges. With ongoing advancements, welded mesh will remain a vital material in the pursuit of innovative and resilient infrastructure.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025