Dec . 13, 2024 15:37 Back to list

welded iron wire mesh 50x50 factories

The Importance and Applications of Welded Iron Wire Mesh A Focus on 50x50 Factories

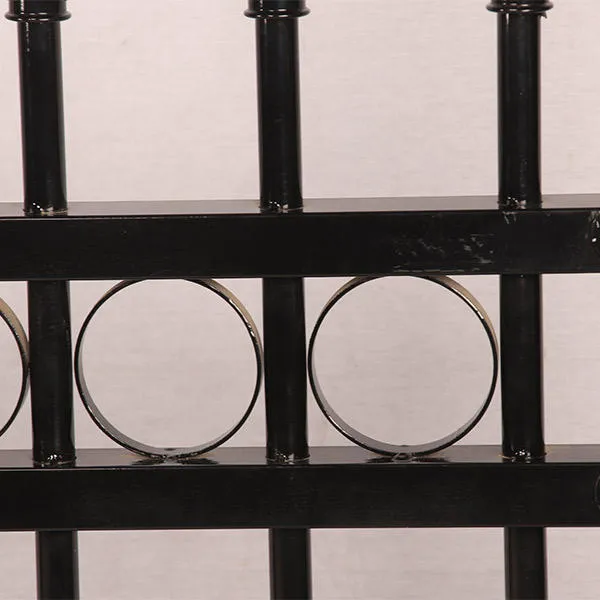

Welded iron wire mesh has emerged as a fundamental material across various industries due to its strength, durability, and versatility. Among the many specifications available, the 50x50 mm welded iron wire mesh is particularly noteworthy, enjoying widespread use in both construction and industrial applications. This article will explore the manufacturing processes, properties, and diverse applications of 50x50 welded iron wire mesh and highlight the significance of factories dedicated to its production.

Manufacturing Process

The production of welded iron wire mesh begins with the selection of high-quality iron wire, which is often galvanized to enhance its resistance to corrosion. The wire is then arranged in a grid pattern, typically with 50 mm spacing between the horizontal and vertical wires. Once the wire is positioned, it undergoes a welding process where the intersections are fused together using electric current. This ensures a robust and stable structure capable of withstanding various loads and stresses.

After the welding process, the mesh is subjected to several quality control measures to verify its strength, dimension accuracy, and overall durability. Factories specializing in the production of 50x50 welded iron wire mesh pay particular attention to these quality checks, ensuring compliance with industry standards and customer specifications. The final product is often rolled or cut into sheets for convenient handling and transportation.

Properties of 50x50 Welded Iron Wire Mesh

One of the significant advantages of 50x50 welded iron wire mesh is its outstanding tensile strength. The method of welding prevents the wires from loosening or deforming under pressure, making it ideal for applications that require structural integrity. Additionally, the mesh's uniform grid pattern provides consistent spacing that aids in effective load distribution, enhancing its functionality in various applications.

welded iron wire mesh 50x50 factories

Furthermore, the galvanized coating enhances the mesh's resistance to environmental factors, including moisture and chemicals, thereby prolonging its lifespan

. Whether used in outdoor structures or internal applications, the welded iron wire mesh can maintain its performance even in harsh conditions.Applications of 50x50 Welded Iron Wire Mesh

The applications of 50x50 welded iron wire mesh are extensive and varied. In construction, it serves multiple purposes, including concrete reinforcement and fencing. As a concrete reinforcing mesh, it reinforces slabs, walls, and beams, helping to control cracking and enhance durability. Its robust nature allows it to effectively distribute weight and stress, which is crucial in modern construction practices.

In terms of fencing, 50x50 welded iron wire mesh is an excellent choice for areas that require security and visibility, such as residential properties, commercial facilities, and agricultural land. Its transparent nature allows for visibility while maintaining a strong barrier against intruders. Moreover, it can be customized in terms of height and coating to suit specific security needs.

In the industrial sector, this type of wire mesh is frequently used as partitioning in warehouses and manufacturing units, providing a flexible solution for creating designated areas within a larger space. It is also used in the production of shelves, racks, and cages for various storage solutions.

Conclusion

The role of 50x50 welded iron wire mesh in modern industries cannot be overstated. Its superior strength, durability, and versatility make it an essential component in construction, fencing, and industrial applications. Factories dedicated to producing this mesh play a crucial role in ensuring quality and availability, catering to the growing demands of various sectors. As industries continue to evolve and innovate, the significance of welded iron wire mesh, particularly in the 50x50 specification, will likely increase, confirming its status as a reliable and indispensable material in the market.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025